A kind of production method of high flatness cold-rolled strip steel

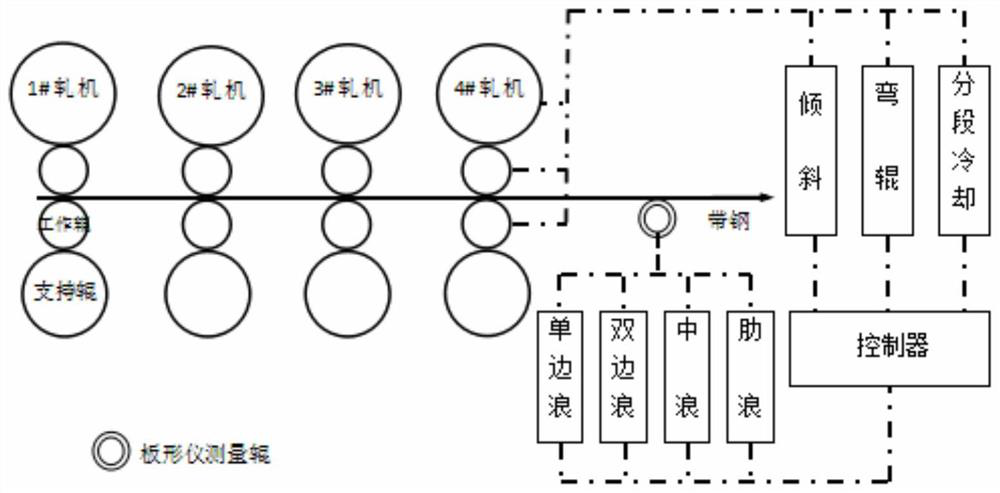

A technology for cold-rolled strip steel and production methods, which is applied in metal rolling, metal rolling, length measuring devices, etc., can solve the problems of control time lag, difficult to change, insufficient adjustment ability, etc., and achieves elimination of shape detection and adjustment. The effect of lag, high-quality product rate improvement, and getting rid of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

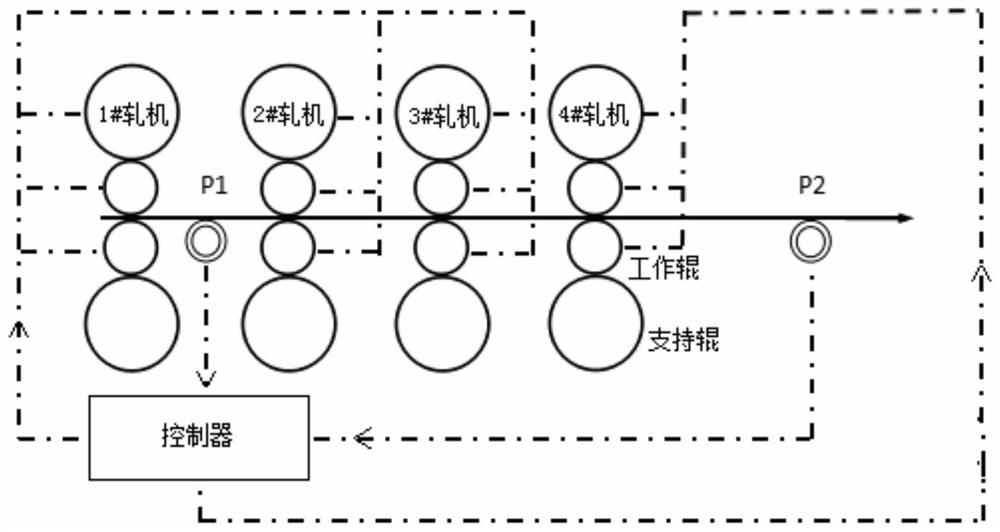

[0047] 1. P1 shape detection and adjustment:

[0048] incoming section ( Figure 4 ) → After rolling by 1# rolling mill → P1 detects the unilateral wave on the A side of the strip → The detected value is transmitted to the controller → The controller gives the inclination adjustment value of the 1#~3# frame rolling mill → The 1#~3# frame rolling mill is carried out Inclination adjustment → The 1#~3# rolling mills carry out the inclination adjustment for the strip shape.

[0049] 2. Distribution of shape adjustment:

[0050] 1# rolling mill feedback adjustment amount is 45%; 2# rolling mill feedforward adjustment amount is 35%; 3# rolling mill feedforward adjustment amount is 20%; 4# rolling mill micro feedback compensatory adjustment.

[0051] 3. P2 shape detection and adjustment

[0052] (1) After the strip shape is adjusted by the first three rolling mills → at the exit of the 4# rolling mill, the unilateral wave on the A side of the strip steel is detected by P2 → the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com