Universal positioner for drilling center hole

A technology for drilling center holes and locators, which is applied in the field of machinery and can solve the problems of multiple specifications of drilling templates, inconvenient management, and skewed center holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

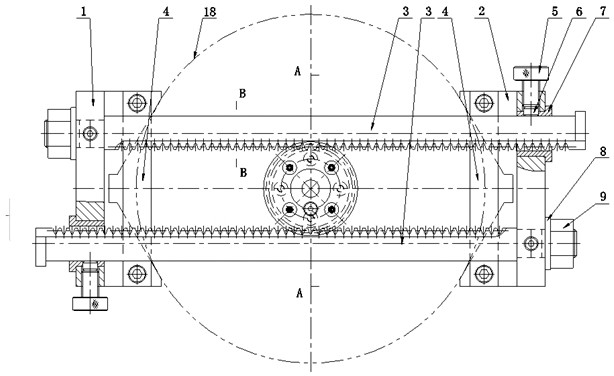

[0024] Primary technical conditions:

[0025] 1. The two rack rods should be processed to the same dimensional accuracy;

[0026] 2. The left V-shaped body and the right V-shaped body should be processed to the same dimensional accuracy;

[0027] 3. The number of gear teeth must be an even number.

[0028] 4. Related technical parameters:

[0029] The number of teeth on the rack bar is Z=54, the modulus m=1.5, the distance L1 from the first tooth groove to the center line of the gear is 108.383mm, and the dimension reference L2 of the first tooth of the two racks is 10±0.5mm. (The number of gear teeth Z=32, the modulus m=1.5, the number of span measuring teeth is 4, and the length of the common normal line is 16.1709)

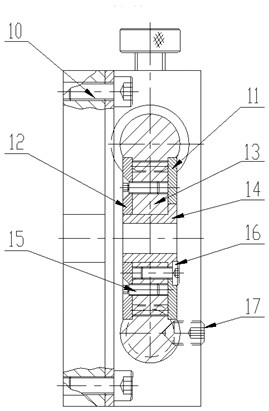

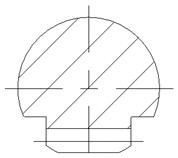

[0030] A universal positioner for drilling center holes, comprising a left V-shaped body 1 and a right V-shaped body 2, two rack bars 3 are arranged between the left V-shaped body 1 and the right V-shaped body 2, and the two rack bars 3 are opposite to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com