Inflation-free hollow tire and manufacturing method thereof

A non-pneumatic, tire technology, used in non-pneumatic tires, tire parts, tires, etc., can solve the problem of load support characteristics and noise, vibration, and ride characteristics can not have both, poor load support characteristics, noise, vibration and ride comfort. and other problems, to achieve the effects of excellent ride comfort, improved bearing capacity and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also includes the preparation method of air-free hollow tire, comprising the following steps:

[0055] ①Put the rubber and auxiliary materials into the internal mixer to mix the mixed rubber, and then roll it into a rubber diaphragm with a thickness of 11-25mm through the calender for many times;

[0056] ②Calculate the quality of the rubber diaphragm required for each layer of the inner ring layer, the middle ring layer, the hollow layer and the outer ring layer, and set aside;

[0057] ③Add the rubber diaphragm of the quality required for the inner ring layer into the mold, pre-vulcanize at 110-163°C for 14-18 minutes, open the left and right flaps of the inner ring layer of the mold, and replace the left and right flaps required by the middle ring layer After adding the rubber diaphragm of the quality required for the middle ring layer, close the left and right flap molds required for the middle ring layer, pre-vulcanize at 110-163°C for 3-4 min...

Embodiment 1

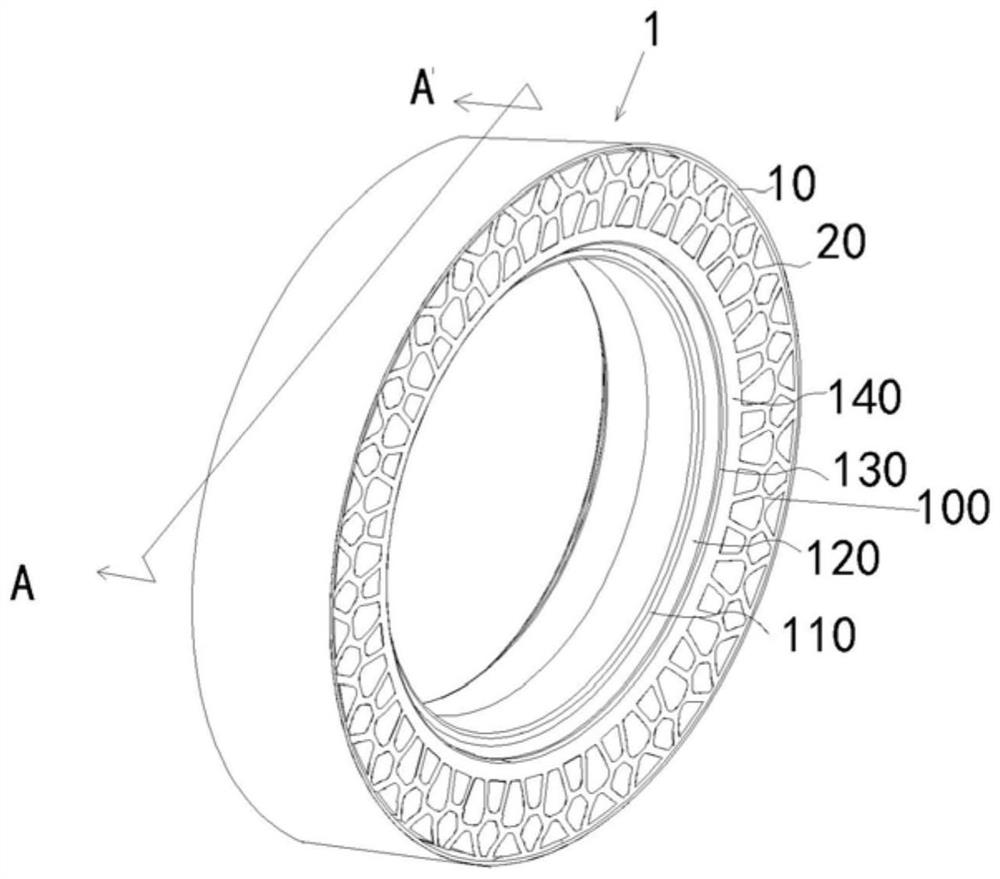

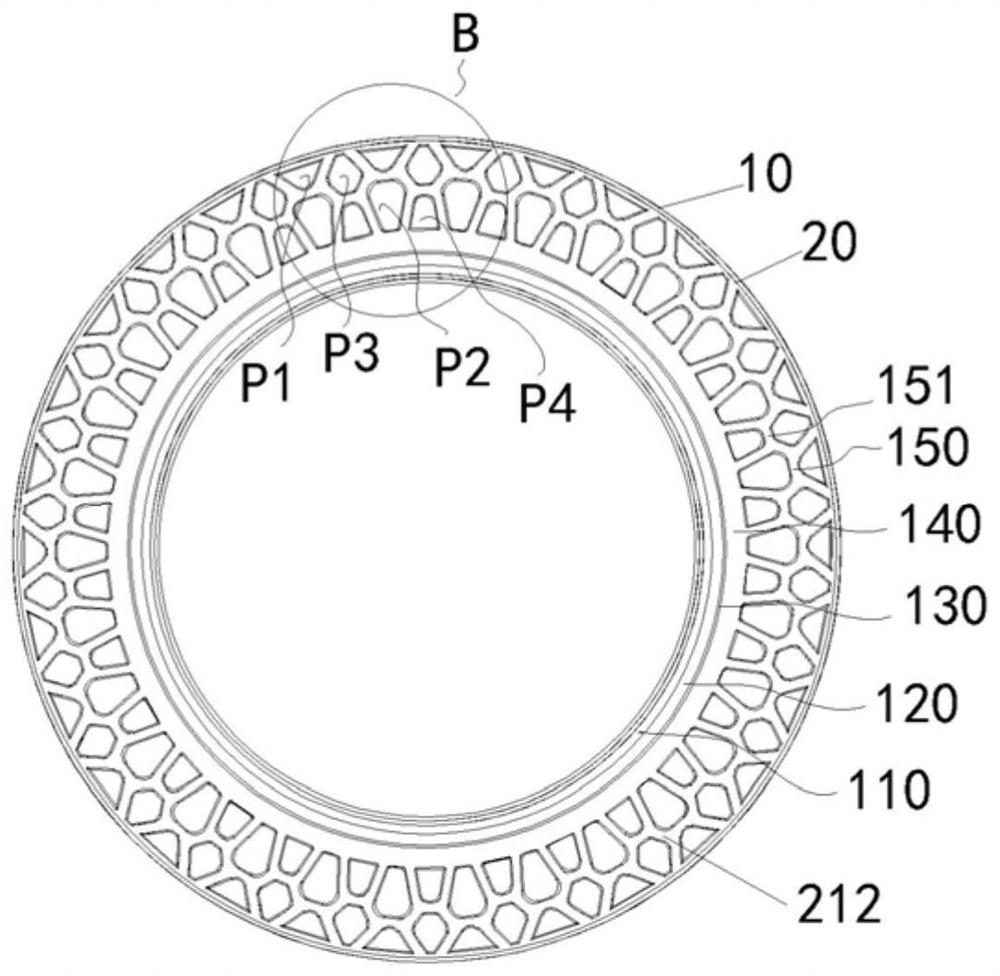

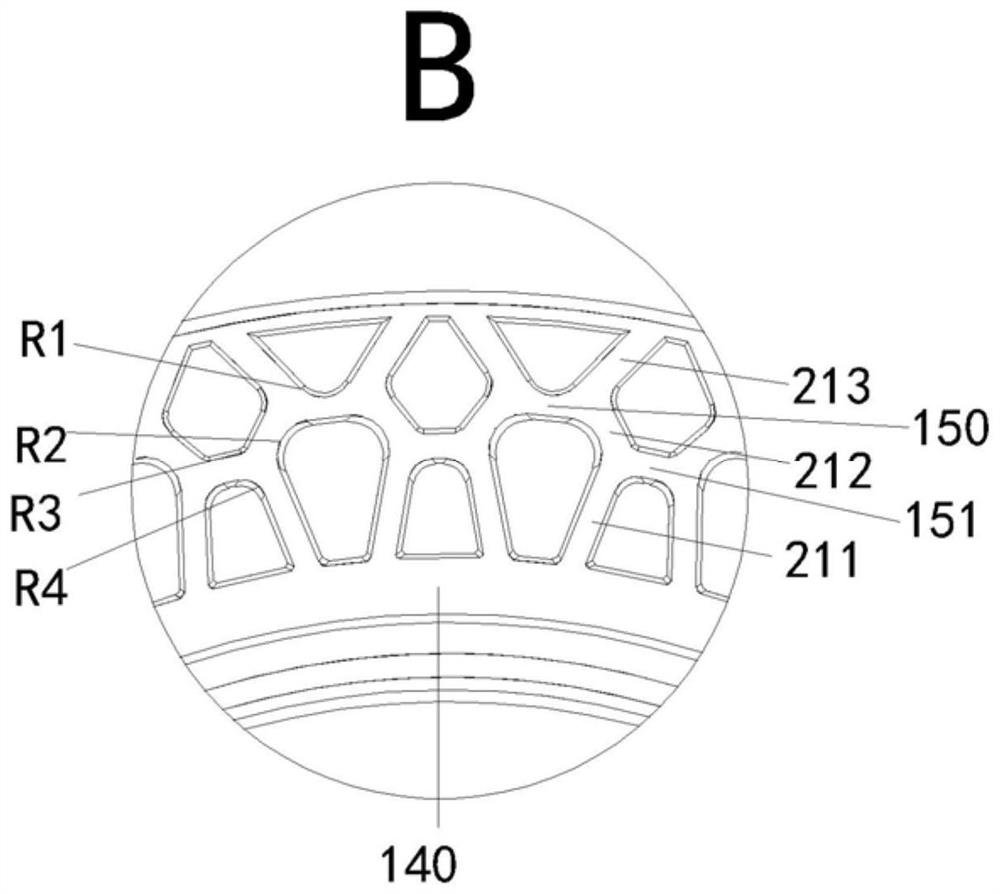

[0068] A kind of air-free hollow tire 1, such as Figure 1~5 As shown, from the inside to the outside are the inner ring layer, the middle ring layer, the hollow layer 100 and the outer ring layer 20, wherein the inner ring layer is the belt layer 110 and the bead layer 120 from the inside to the outside, and the middle ring layer is from the inside to the outside. The outer ones are the shoulder layer 130 and the middle inner ring layer 140 in sequence;

[0069] The outermost edge of the outer ring layer 20 is the tread 10, the tread 10 is in contact with the road surface, the belt layer 110 is installed on the rim of the vehicle, and the hollow layer 100 arranges multiple sets of shock absorbing units along the circumferential array, and each set of shock absorbing units Including the first shock-absorbing hole P1, the second shock-absorbing hole P2, the third shock-absorbing hole P3 and the fourth shock-absorbing hole P4, such as image 3 The shown corners of the first sho...

Embodiment 2

[0076] The preparation method of the non-inflation hollow tire described in embodiment 1, comprises the following steps:

[0077] ①Put the rubber and auxiliary materials into the internal mixer to mix the mixed rubber, and then roll it into a rubber diaphragm with a thickness of 11-25mm through the calender for many times;

[0078] ②Calculate the quality of the rubber diaphragm required for each layer of the inner ring layer, the middle ring layer, the hollow layer and the outer ring layer, and set aside;

[0079]③Add the rubber diaphragm of the quality required for the inner ring layer into the mold, pre-vulcanize at 110-163°C for 14-18 minutes, open the left and right flaps of the inner ring layer of the mold, and replace the left and right flaps required by the middle ring layer After adding the rubber diaphragm of the quality required for the middle ring layer, close the left and right flap molds required for the middle ring layer, pre-vulcanize at 110-163°C for 3-4 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com