Connecting and disconnecting device and disconnecting method for deep sea escape cabin

A technology of release device and escape cabin, which is applied in the field of deep-sea release equipment, can solve the problems that the flange of the locking ring cannot just match the groove of the fence, the escape cabin cannot be released and separated, and the driving mode is single, so as to improve the reliability of release and improve Unlock reliability, avoid stuck effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

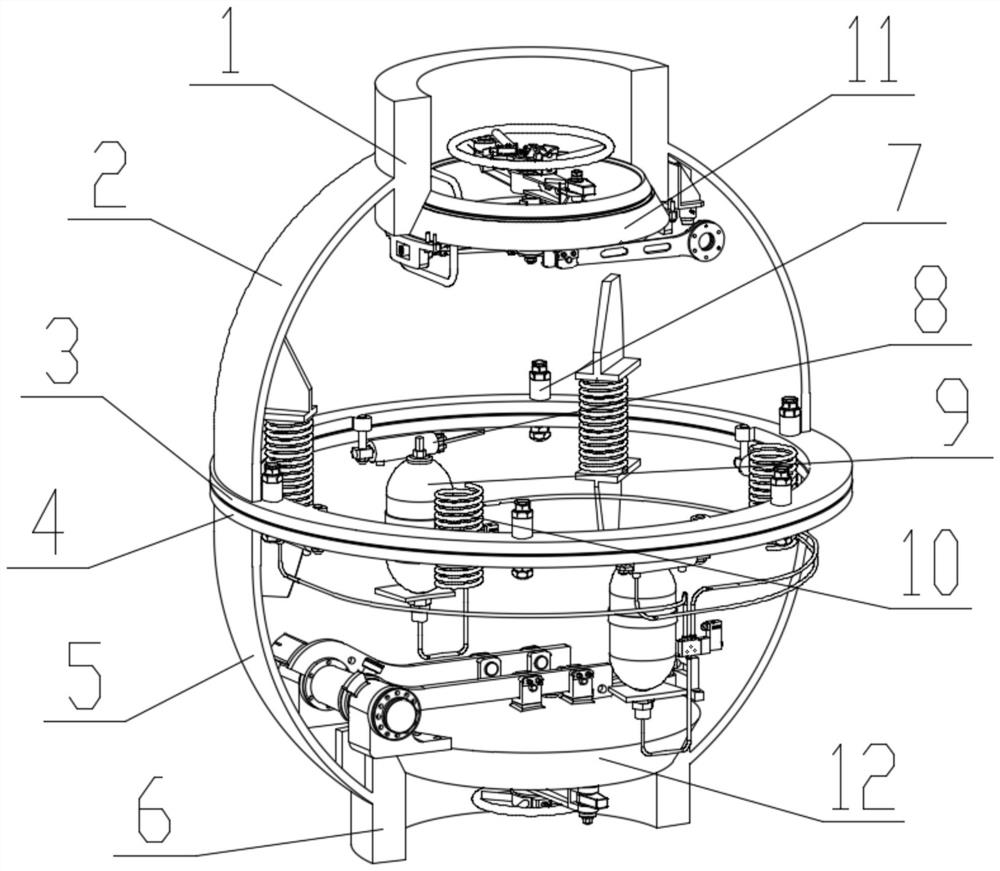

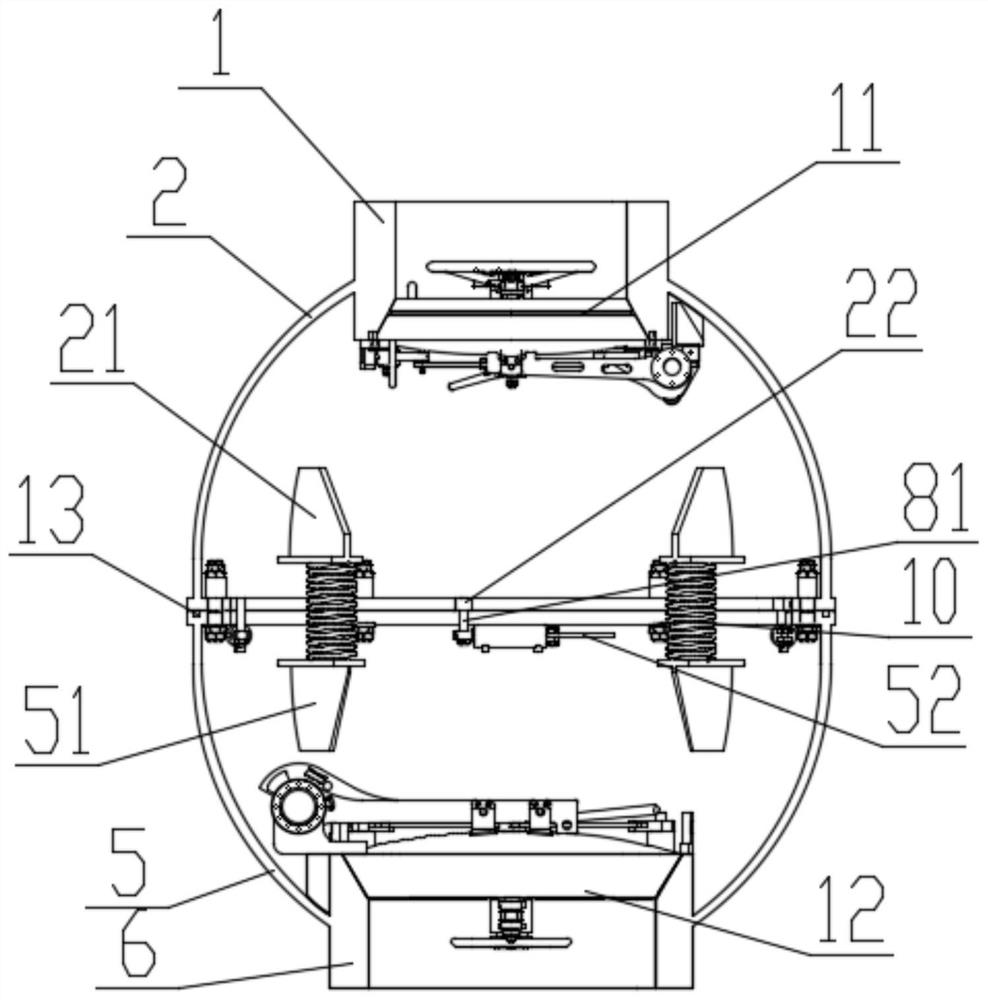

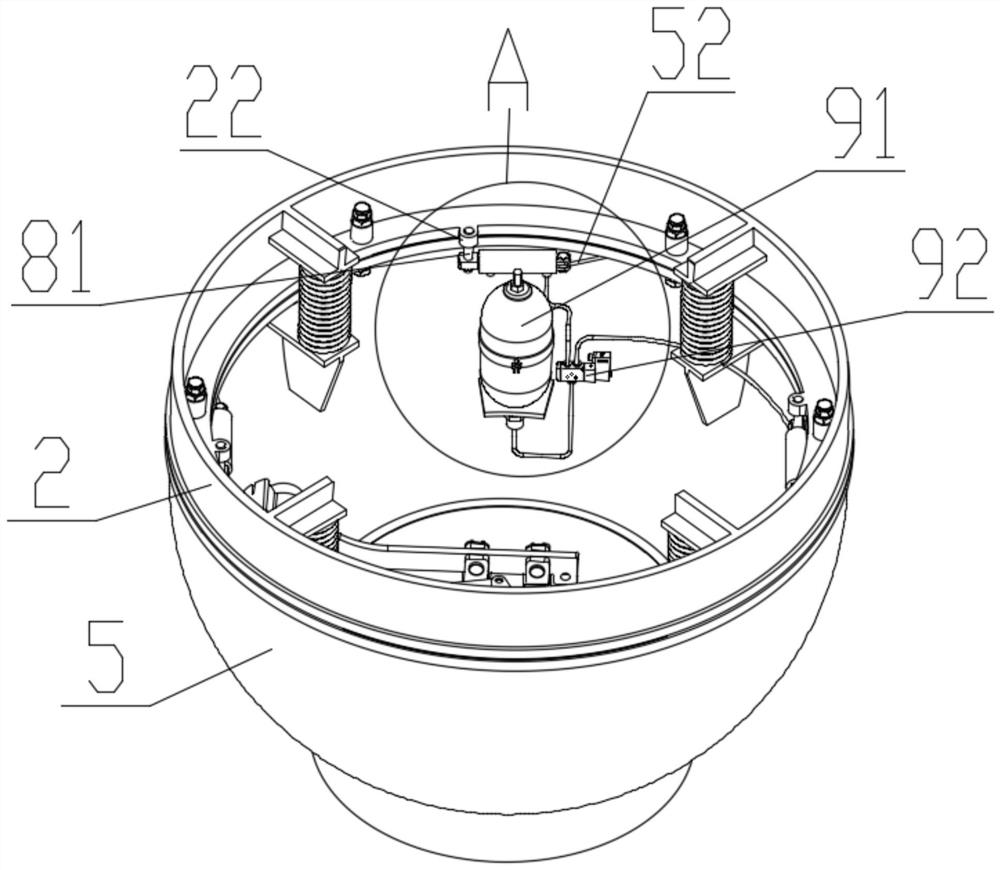

[0053] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0054] Such as Figure 1-Figure 9 As shown, the connection and release device for the deep-sea escape cabin of this embodiment includes an upper well 2 and a lower well 5 all in a hemispherical structure. The top of the upper well 2 is provided with an upper passage wall 1, and the upper passage The enclosure wall 1 is connected to the manned ball of the escape cabin, the bottom of the upper enclosure 2 is provided with an upper docking flange 3; the top of the lower enclosure 5 is provided with a lower docking flange 4, and the bottom of the lower enclosure 5 is provided with a lower passage enclosure wall 6. The lower passage wall 6 is connected to the manned cabin of the deep-sea manned submersible;

[0055] The upper butt flange 3 and the lower butt flange 4 are fixedly connected by explosive bolts 7, and the flange surface is sealed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wedge angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com