Full-automatic production line for disc single detonators

A fully automatic, production-line technology, applied in detonators, offensive equipment, etc., can solve the problems of low production efficiency, many human contact processes, low safety, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

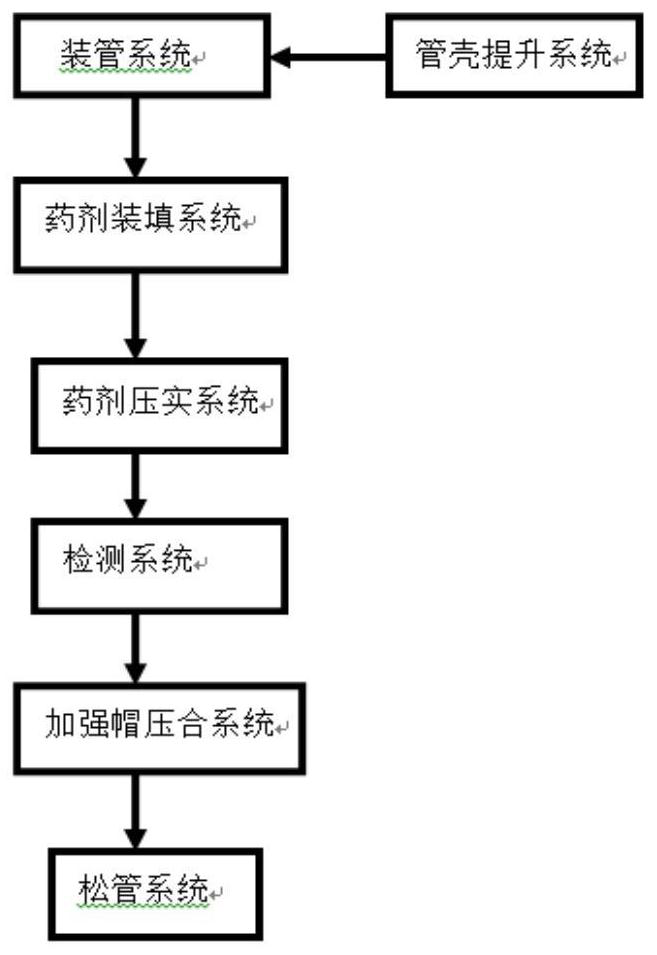

[0064]A fully automatic production line for disc single-shot detonators, which sequentially includes a casing lifting system, a tube loading system, a drug filling system, a drug compacting system, a detection system, a reinforcing cap pressing system, and a tube loosening system. The casing lifting system It is a pipe hoist 14, and the pipe outlet end of the pipe hoist 14 corresponds to the pipe inlet end of the pipe loading system. The transportation of single-shot detonators between each process is realized through the chain plate transmission equipment 17 between the pipe systems. The chain plate transmission equipment 17 is arranged on the side of each system, and the two sides of the chain plate transmission equipment 17 are provided with guide blocks 11. The guide block 11 is set along the transport direction of the chain plate conveying equipment 17, and the tube loading system, drug filling system, detection system, drug compaction system, reinforced cap pressing syste...

Embodiment 2

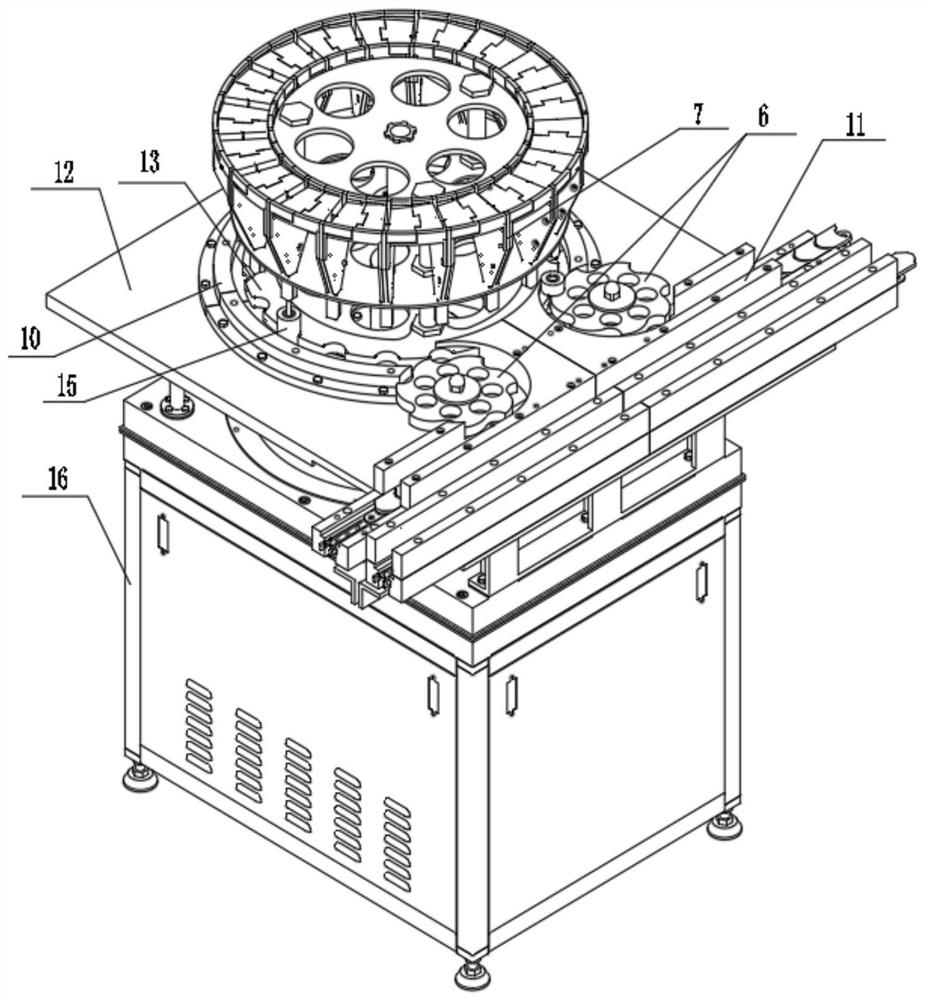

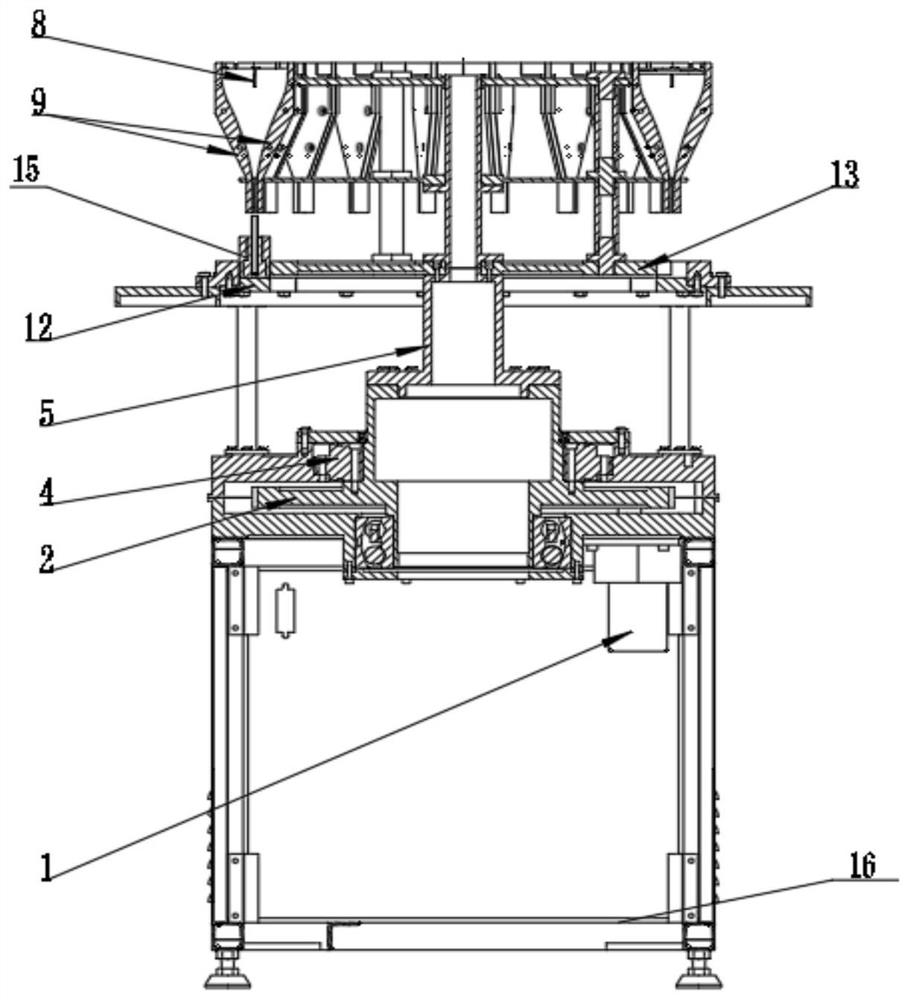

[0067] Such as Figure 2-10 and Figure 14 As shown, the tube loading system is used to fill the tube shell into the single-shot mold 15, and includes a rotating tube turning system. The chain plate transmission device 17 is arranged on the side of the rotating tube turning system. The rotating tube turning system includes a flange seat 5, The center dial 13 and the tube turning device, the center dial 13 is connected with the central rotary table 2 through the flange seat 5, the center dial 13 is provided with a guide ring 10 fixed on the mold running platform 12, the tube turning device and the center dial The discs 13 are coaxially connected, and the tube turning device is composed of a plurality of turning bodies 7, the turning bodies 7 include a left turning body 701 and a right turning body 702, and both sides of the top of the left and right turning bodies are provided with arc-shaped stoppers 705, The left side of the left turning body 701 is provided with a dovetail ...

Embodiment 3

[0088] Such as Figure 11-14 As shown, the medicament filling system includes a drug charging device for filling medicament in the tube shell, and the drug charging device includes a jacking track 26, a jacking shaft 24, a jacking block 23, a metering plate 20, a central rotating shaft 28 and Leakage plate 22, the track surface of jacking track 26 is inclined surface and is installed on transmission box 27 top surfaces, and jacking track 26 is provided with rolling bearing 25, and rolling bearing 25 connects an end of jacking shaft 24, and the other end of jacking shaft 24 One end is connected to the lifting block 23, and the lifting block 23 is located directly below the single-shot mold 15. The lower end of the central rotating shaft 28 extends to the inside of the transmission box 27 and is coaxially connected with the central rotating table 2. Plate 20 is provided with medicine hopper 19, and the below of measuring medicine plate 20 is provided with tray 29, and the medici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com