High-precision positioning and mounting device for common-plate flange air pipe

A positioning and installation, common plate flange technology, used in measuring devices, optical devices, pipeline laying and maintenance, etc., can solve problems such as affecting appearance and quality, prone to accidents, abnormal noises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

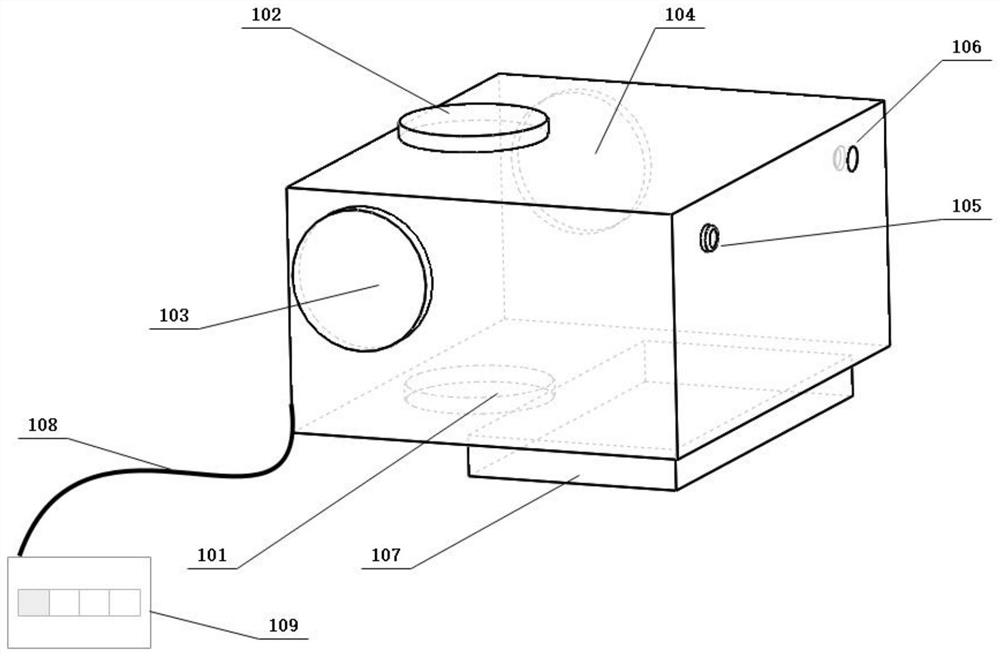

[0032] as attached image 3 , a high-precision positioning and installation device for a common-plate flange air duct, the installation device includes a positioning suction cup, a distance sensor, a sounder, a remote control, and a control module; The installation device is fixed on one end of the pipeline; the distance measuring sensor is used to measure the distance from the four walls of the pipeline to the device; The distance value is converted into a sound signal in real time; the remote control is connected to the control module for controlling the installation device; the control module is used for controlling each part of the installation device to work;

[0033] The positioning installation device includes a module A and a module B; the module A and the module B have the same structure and function; the module A and the module B can be combined with each other using a connection structure, and can transmit electrical signals after being combined;

[0034] The posit...

Embodiment 2

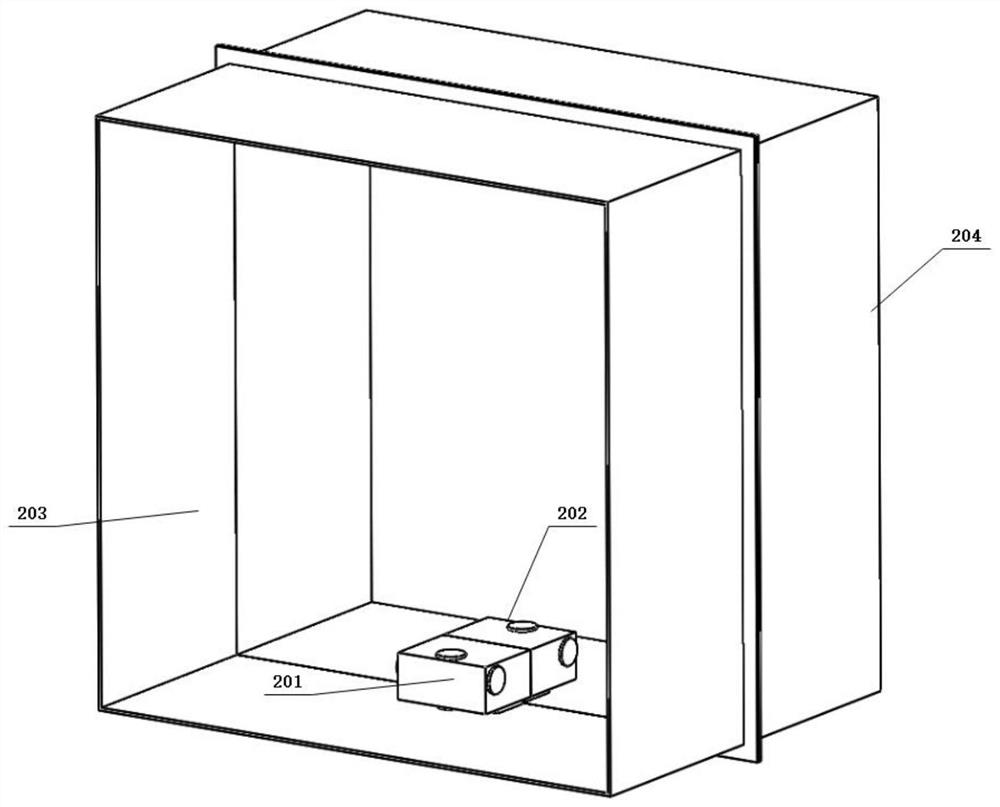

[0067] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements on the basis thereof; Figure 4 , a high-precision positioning and installation device for a common-plate flange air duct, the installation device includes a positioning suction cup, a distance sensor, a sounder, a remote control, and a control module; The installation device is fixed on one end of the pipeline; the distance measuring sensor is used to measure the distance from the four walls of the pipeline to the device; The distance value is converted into a sound signal in real time; the remote control is connected to the control module for controlling the installation device; the control module is used for controlling each part of the installation device to work;

[0068] The positioning installation device includes a module A and a module B; the module A and the module B have the same structure and function; the module A and...

Embodiment 3

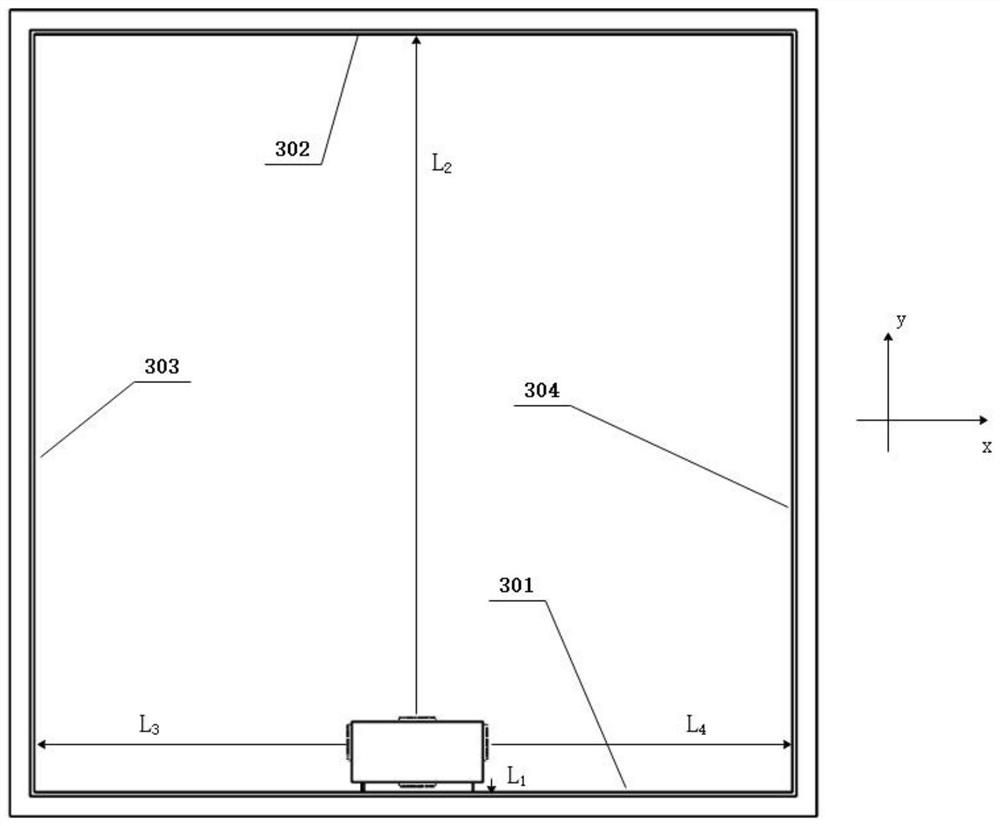

[0086] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements on the basis thereof; Figure 5 , a high-precision positioning and installation device for a common-plate flange air duct, the installation device includes a positioning suction cup, a distance sensor, a sounder, a remote control, and a control module; The installation device is fixed on one end of the pipeline; the distance measuring sensor is used to measure the distance from the four walls of the pipeline to the device; The distance value is converted into a sound signal in real time; the remote control is connected to the control module for controlling the installation device; the control module is used for controlling each part of the installation device to work;

[0087] The positioning installation device includes a module A and a module B; the module A and the module B have the same structure and function; the module A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com