Motion mechanism plane three-degree-of-freedom measuring device and method based on PSD sensor

A technology of motion mechanism and measuring device, applied in the direction of measuring device, optical device, instrument, etc., can solve the problem of limited freedom of sensor measurement, and achieve the effect of satisfying high-speed measurement feedback and high measurement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

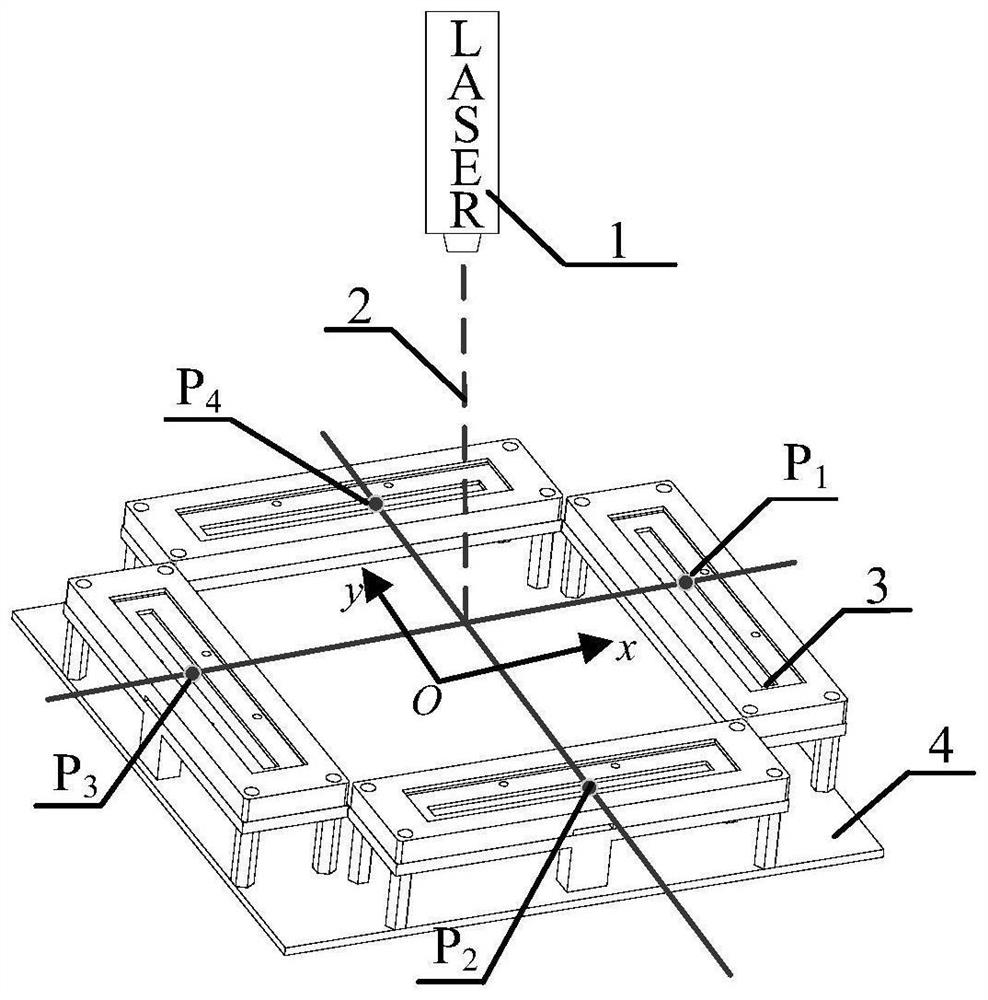

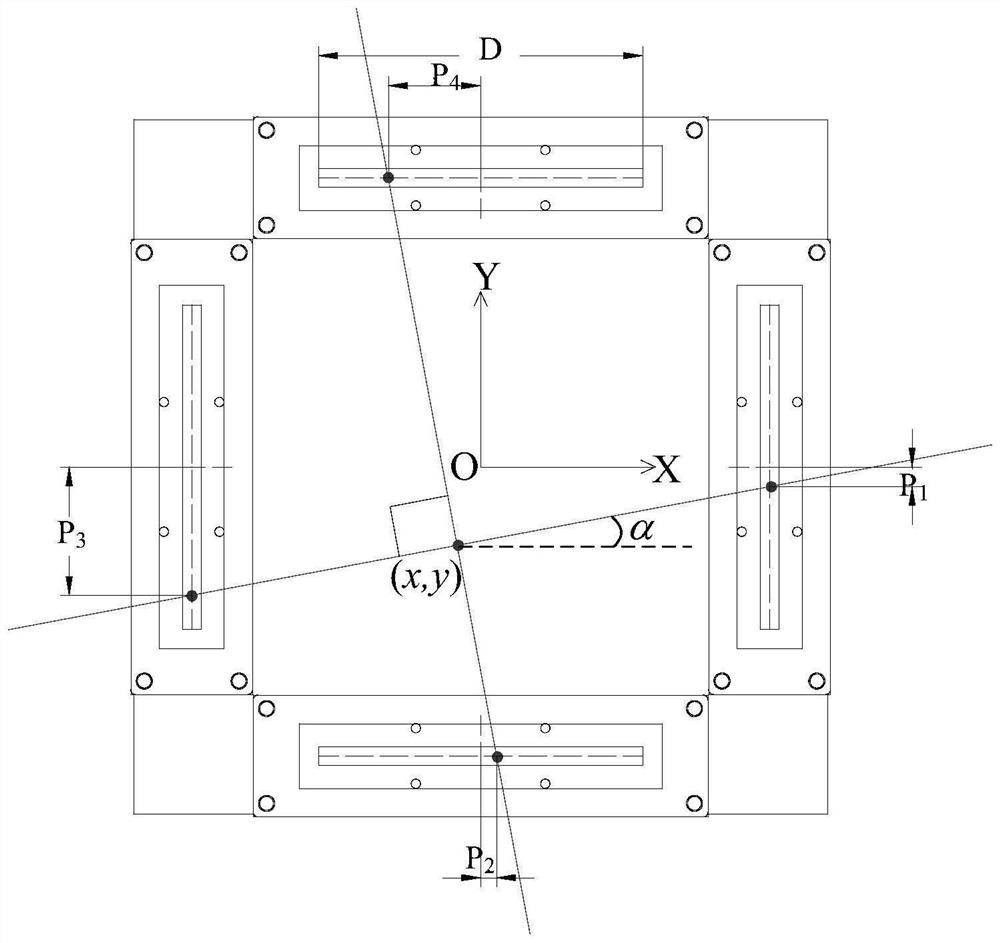

[0025] Such as figure 1 As shown, in this embodiment, the measurement device mainly includes a PSD sensor measurement part and a laser part, and there is relative movement between the PSD sensor measurement part and the laser part. In this embodiment, according to the characteristics of the mechanism to be measured, the measured object can be set on the moving platform, the PSD sensor measurement part can be fixed on the fixed platform, and the laser can be driven by the moving mechanism to measure; The mechanism drives the measurement part of the PSD sensor to perform measurement.

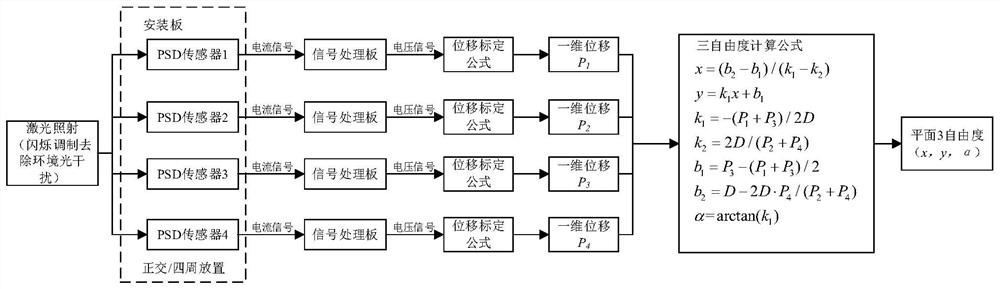

[0026] Among them, the PSD sensor measurement part includes a sensor installation base plate, 4 one-dimensional PSD sensors, 4 signal processing boards, and an 8-channel AD signal acquisition card. The 4 signal processing boards are respectively connected with 4 one-dimensional PSD sensors. After the output signal is processed by I-V conversion and voltage amplification, the obtained voltage sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com