Vacuum glass heat insulation performance testing device and method

A vacuum glass and testing device technology, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as low detection efficiency, strictness, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

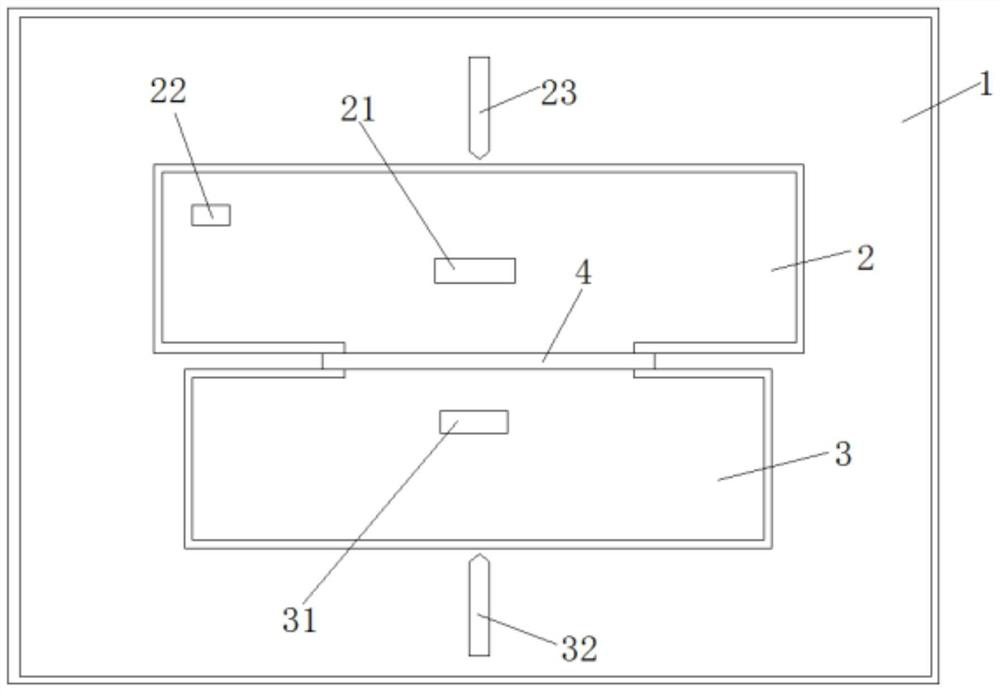

[0026] like figure 1 Shown is the vacuum glass heat insulation performance testing device according to the present invention, including a control system, a quiet room 1, and a sounding box 2 and a receiving box 3 arranged in the quiet room 1. A sounding device 21 and a receiving box 3 are arranged in the sounding box 2 The sound receiver I22 is provided with the sound receiver II31 in the sound receiver 3 .

[0027] The speaker and the receiving speaker are set opposite to each other and placed parallel to the ground. There are openings on the two side walls opposite the emitting and receiving speaker. The sound generator, sound receiver II and the opening are on the same line. Between the opening of the sound box and the sound box; it also includes a sound box pushing mechanism 23 and a sound box pushing mechanism 32, the sound box can move forward and backward under the action of the sound box pushing mechanism, and the sound box can move forward and backward under the effec...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the sounding box and the receiving sound box are placed vertically up and down, the sounding box is fixed on the ground of the silent room, and the receiving sound box is fixed directly above the sounding box, and the sounding box can be moved under the action of the sound box pushing mechanism. Moving up and down, the affected speaker can move up and down under the action of the pushing mechanism of the affected speaker.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the sound emitting box and the receiving sound box are placed vertically up and down, the receiving sound box is fixed on the ground of the silent room, the sound emitting box is fixed directly above the receiving sound box, and the sound emitting box can be moved under the action of the sound box pushing mechanism. Moving up and down, the affected speaker can move up and down under the action of the pushing mechanism of the affected speaker.

PUM

| Property | Measurement | Unit |

|---|---|---|

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com