Workpiece deformation simulation prediction method for optimizing initial residual stress based on MSVR-GA

A residual stress, simulation prediction technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problems of inaccurate initial residual stress data, low simulation prediction model accuracy, etc. The effect of input dimension reduction and model simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

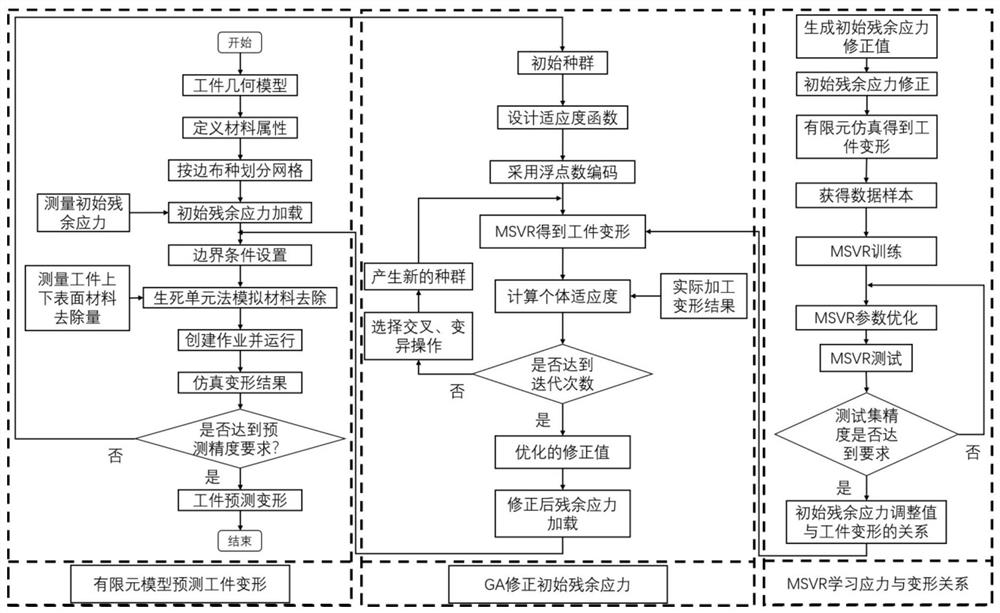

[0056] In order to further understand the workpiece deformation simulation prediction method based on MSVR-GA optimization of initial residual stress, the present invention will be described in detail below in conjunction with the embodiments, including the following steps:

[0057] A method for simulation prediction of workpiece deformation based on MSVR-GA optimization of initial residual stress, mainly including the following steps:

[0058] The workpiece is a copper sheet with a diameter of 200mm and a thickness of 2mm.

[0059] The first step is to obtain the initial data

[0060] 1.1) Carry out heat treatment on the same batch of workpieces, one of which is marked as A 1 , and the remaining workpieces are recorded as A 2 .

[0061] 1.2) Use a residual stress measuring instrument to measure A 1 The initial residual stress inside the workpiece, the residual stress is measured every 50 μm depth, and the residual stress distribution along the thickness direction of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com