Double-station full-automatic double-sided grinding machine integrated with robot

A double-sided grinding and robot technology, applied in the field of polishing machines, can solve the problems of low workpiece grinding efficiency, small application range, and inability to automatically load and unload materials, and achieve the effects of improving grinding efficiency, grinding quality, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

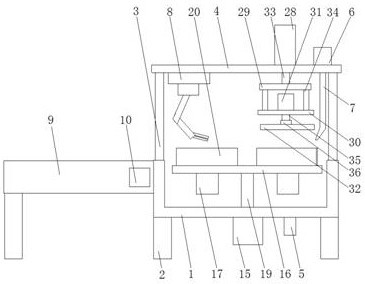

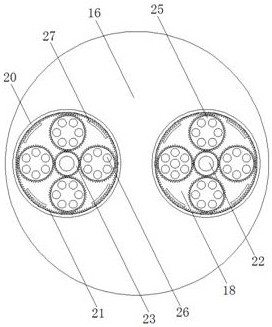

[0022] as attached Figure 1-4As shown, a double-station full-automatic double-sided grinding machine fused with a robot, including a box body 1, a transfer device, a lower grinding structure, a clamping robot 8, and an upper grinding structure, is characterized in that: the box body 1 Set on the bracket 2, the box body 1 is provided with a column 3, and a top plate 4 is arranged on the top of the column 3; the box body 1, the bracket 2, and the column 3 are connected by welding to strengthen the box body 1 and the bracket 2, The connection strength between the columns 3, and then improve the structural strength of the double-sided grinding machine, the transfer device includes a beam 9, a motor 10, a rotating roller 11, a conveyor belt 12, and one end of the beam 9 is arranged on the box 1 on the outer wall, the other end is set on the bracket 2, and a bearing 13 is set on the beam 9, the motor 10 is set on the beam 9, the two ends of the rotating roller 11 are set on the con...

Embodiment 2

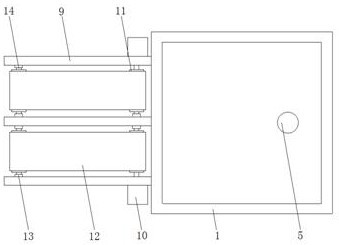

[0030] as attached Figure 5-6 as shown,

[0031] A double-station full-automatic double-sided grinding machine integrated with a robot, including a box body 1, a transfer device, a lower grinding structure, a clamping robot 8, and an upper grinding structure. It is characterized in that: the box body 1 is set on the bracket 2, a column 3 is provided on the box body 1, and a top plate 4 is provided on the top of the column 3; the box body 1 is connected to the bracket 2 and the column 3 by welding to strengthen the connection between the box body 1 and the bracket 2 and the column 3. The connection strength between them, and then improve the structural strength of the double-sided grinding machine, the transfer device includes a beam 9, a motor 10, a rotating roller 11, a conveyor belt 12, and one end of the beam 9 is arranged on the outer wall of the box 1 , the other end is arranged on the bracket 2, and a bearing 13 is arranged on the beam 9, the motor one 10 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com