Blanking method for FPCA plate die cutting, die cutting method and die cutting device

A mold and blanking technology, which is applied in the processing of insulating substrates/layers, metal processing, electrical components, etc., can solve the problems that the suction nozzle cannot be aligned with the product, increase the product error of the suction nozzle, and affect the suction effect. The effect of convenient positioning, improved cutting speed and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

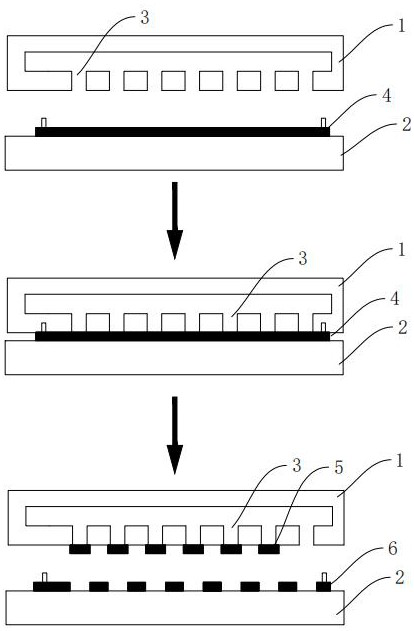

[0031] Embodiment one: see figure 1 Shown, a kind of blanking method of FPCA board die-cutting, this FPCA board die-cutting is finished by upper die 1 and lower die 2 mold closing, after described FPCA board 4 die-cutting, form a plurality of sizes less than 10mm*10mm Product 5, the blanking method comprises the following steps:

[0032] After the die-cutting of the FPCA board 4, the product 5 adsorbed thereon is separated from the lower die 2 while the upper die 1 with the suction hole 3 moves away from the lower die 2; wherein, each One said product 5 is sucked by at least one said suction hole 3, and a plurality of said products 5 formed by one die-cutting are sucked correspondingly by all said suction holes 3 on said upper mold 1 at the same time;

[0033] Moving and positioning the material receiving tray on the lower mold 2, and the lower mold 2 drives the material receiving tray to move toward the upper mold 1 to fit with the upper mold 1;

[0034] After the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com