Push bar for switchable valve train of reciprocating piston internal combustion engine

A valve train, push bar technology, applied in the directions of machines/engines, mechanical equipment, engine components, etc., can solve the problems of the spring tongue that cannot support the swing force, the deflection of the spring tongue, the weakening of the spring tongue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

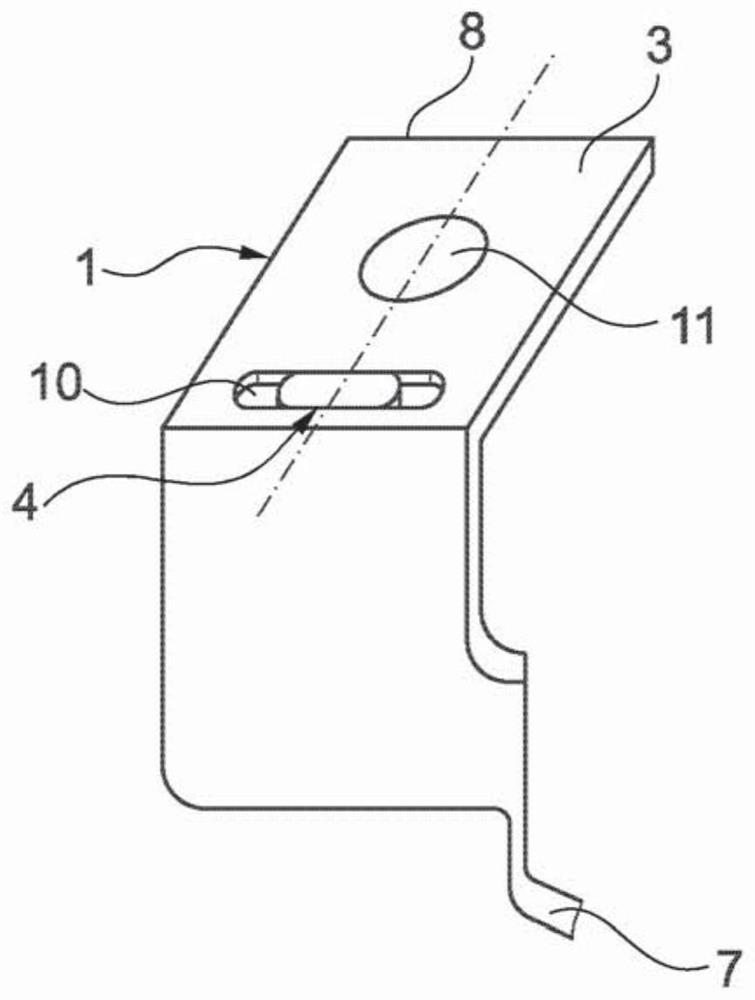

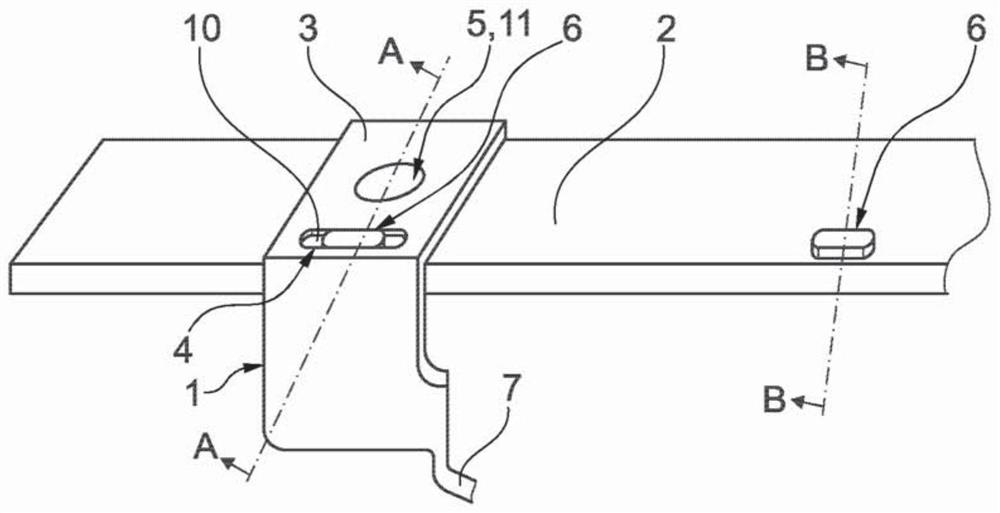

[0018] exist Figures 1 to 4 , the spring tongue marked with 1 is shown in detail, which is fastened to the push bar 2 . The push strip 2 (not shown) is mounted parallel to the camshaft of the internal combustion engine and is designed to be displaceable against spring force by means of a linear actuator.

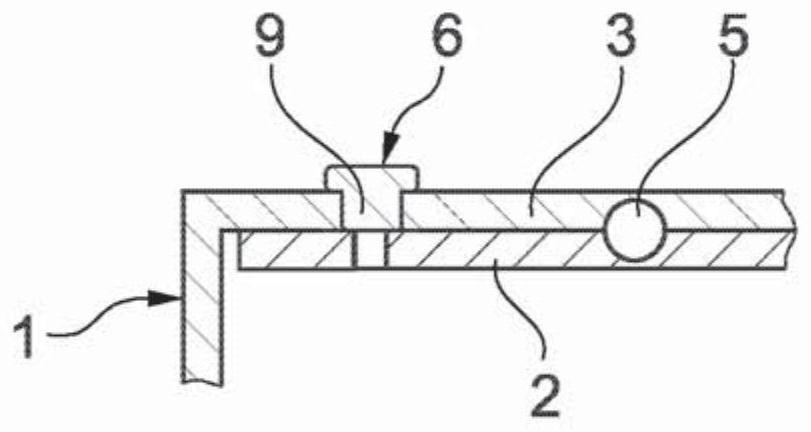

[0019] The spring tongue 1 has a butt strap 3 which is arranged bent over at the upper end of the spring tongue 1 . Adjacent to the bend of the spring tongue 1 , an elongated hole 4 is formed in the butt strap 3 , which is oriented transversely to the butt strap. The spring tongue 1 is arranged aligned on the push bar 2 and is then connected to the push bar 2 via spot welds 5 . Subsequently, the material 9 of the push strip 2 is pressed into the elongated hole 4 by means of punching and self-clinching by means of a tool arranged below the push strip 2 .

[0020] Such as image 3 As shown, the material displacement is carried out, for example by means of a corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com