Load maintaining sheet type multi-way valve

A load holding and multi-way valve technology, applied in the hydraulic field, can solve problems such as oil leakage and arm drop, and achieve the effect of ensuring sealing performance, good sealing effect, and preventing arm drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

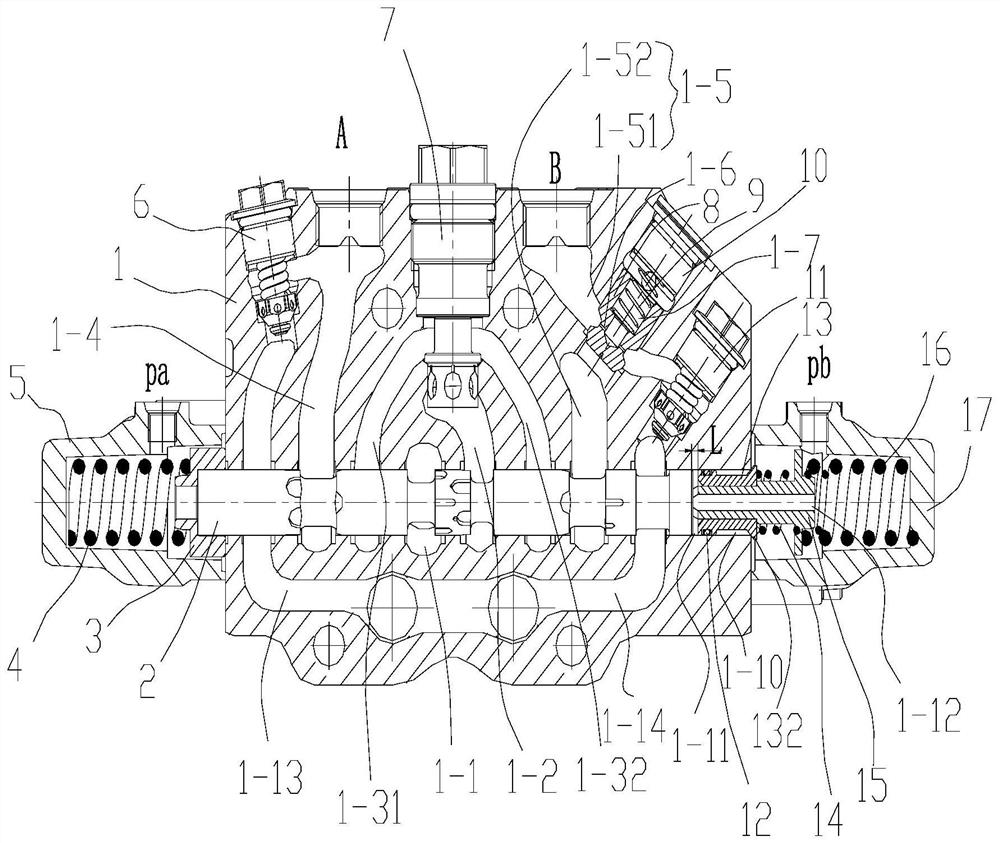

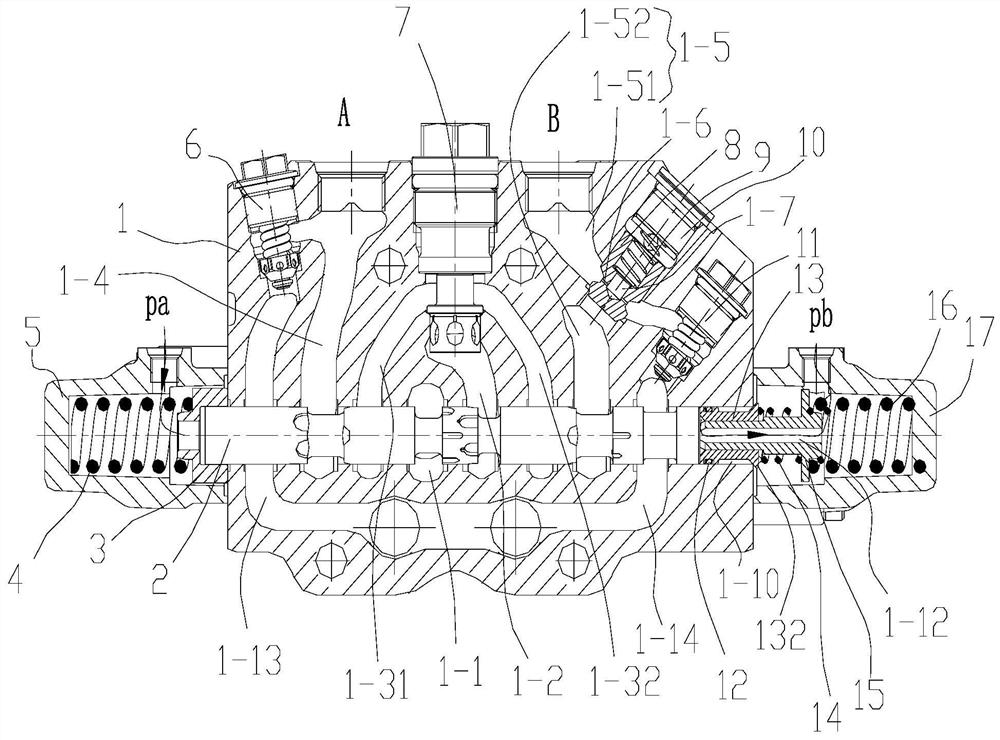

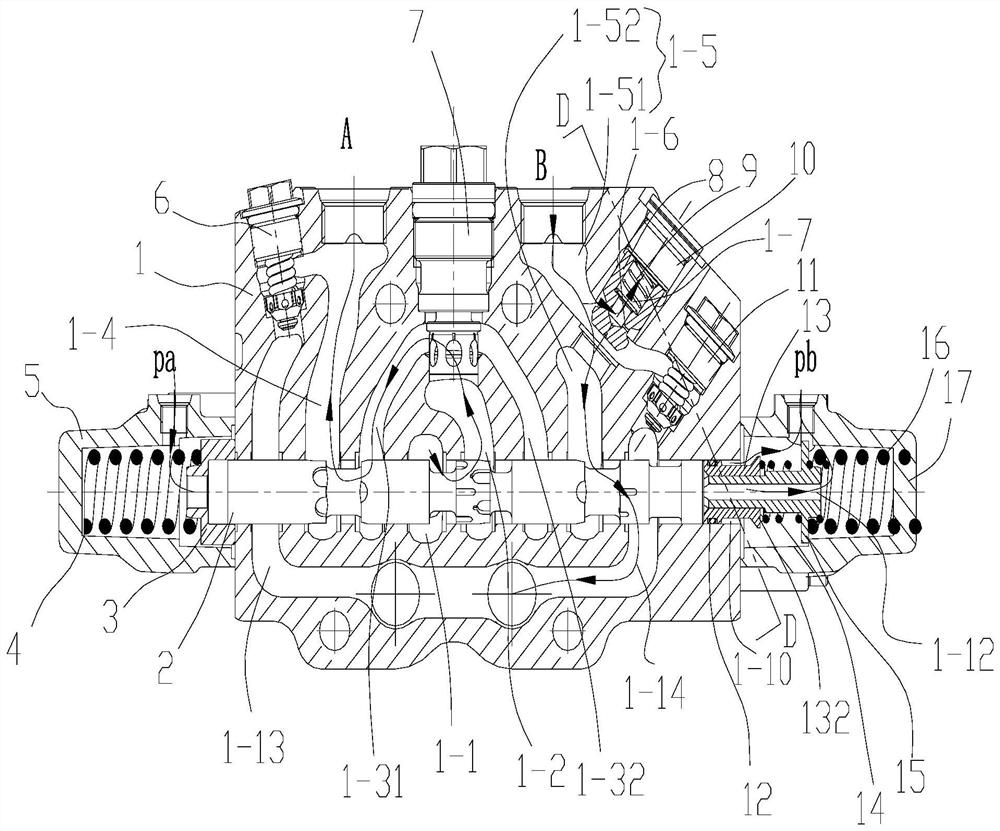

[0061] In the present invention, the valve sleeve 13 is slidingly connected with the ejector rod 15, and the ejector rod 15 is provided with a step for supporting the valve sleeve 13 to the direction of the valve core 2, and the groove on the valve sleeve 13 extends to the sealing structure, and when the ejector rod 15 against the valve sleeve 13, and when the sealing structure of the valve sleeve 13 cooperates with the valve body 1, the end of the ejector rod 15 close to the valve core 2 exceeds the end of the valve sleeve 13 close to the valve core 2 by a distance L, where L can be equal to Figure 8 2x in the middle, so that the valve core 2 first contacts with the ejector rod 15 and then contacts with the valve sleeve 13. There is a device on the valve body 1 or between the valve sleeve 13 and the ejector rod 15 for adjusting the valve before the valve core 2 contacts with the valve sleeve 13. Cover 13 carries out the position-limiting structure of position-limiting.

Embodiment 2

[0063] The valve sleeve 13 is slidingly connected with the ejector rod 15, and the ejector rod 15 is provided with a step for supporting the valve sleeve 13 to the direction of the valve core 2. When body 1 cooperates, such as Figure 11 , the end of the valve sleeve 13 close to the valve core 2 exceeds the end of the ejector rod 15 close to the valve core 2 or both are flush, and the distance between the groove on the valve sleeve 13 and the sealing structure is L, and the valve sleeve 13 is in the groove The size of the outer circle between the sealing structure matches the valve core hole and the valve sleeve 13 can slide in the valve core hole. This embodiment can solve the problem of oil leakage when the valve core 2 is in the neutral position. When the core 2 pushes the valve sleeve 13 to move to the pilot oil chamber, after the sealing structure is separated from the valve body 1, a little oil will flow from the gap between the valve sleeve 13 and the valve core hole to...

Embodiment 3

[0065] The push rod 15 is integrally formed or fixedly connected with the valve sleeve 13, and there is a distance L between the groove of the valve sleeve 13 and the raised portion 132, where L can be equal to Figure 8 2x in , the principle and effect of this embodiment are similar to those of Embodiment 2, and will not be repeated here.

[0066] The limiting structure in Embodiment 1 and Embodiment 2 can be in the form of a movable gear rod or stopper, etc., the gear rod or stopper blocks the valve sleeve 13 before the valve core 2 contacts the valve sleeve 13, the gear rod or the stopper Loosen the valve sleeve 13 after the valve core 2 is in contact with the valve sleeve 13 . In the present invention, the limiting structure is a second elastic element arranged between the valve sleeve 13 and the push rod 15 . The second elastic element is the second spring 14 .

[0067] A first flow passage 1-6 is provided between the cavity 1-7 of the check valve 8 and the second worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com