Rigid beam connecting device for preventing failures of corners of water-cooled wall of tower type supercritical boiler

A supercritical boiler and connecting device technology, applied in the combustion method, combustion chamber, outer cover/lining and other directions, can solve problems such as crack failure of water-cooled wall pipes, and achieve the effects of stress dispersion, wide application range and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

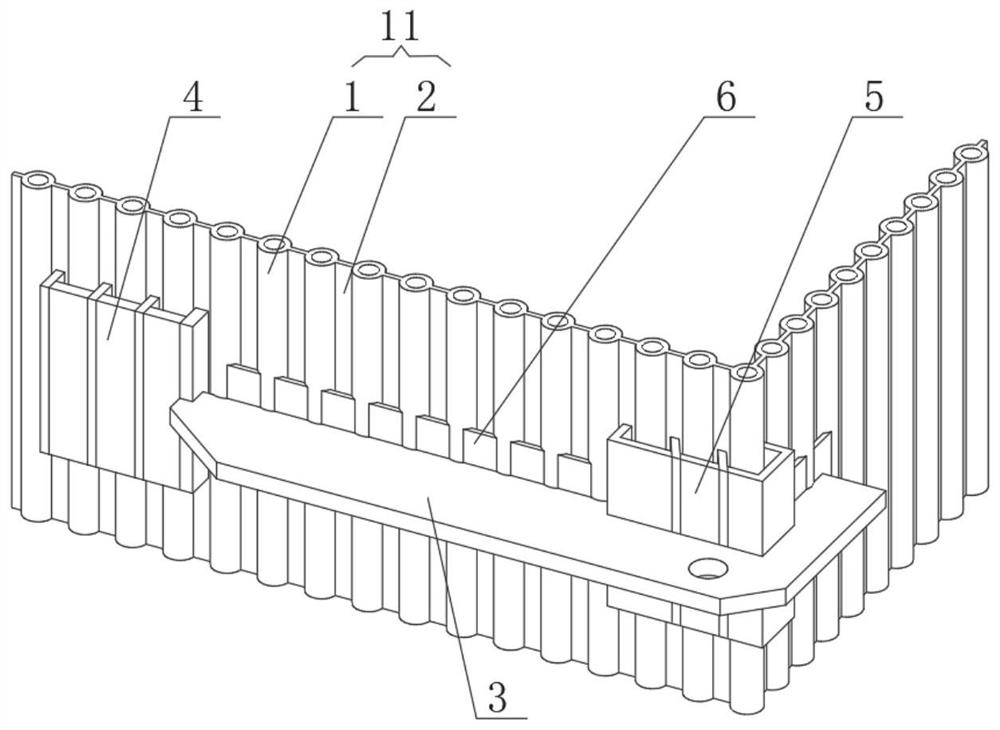

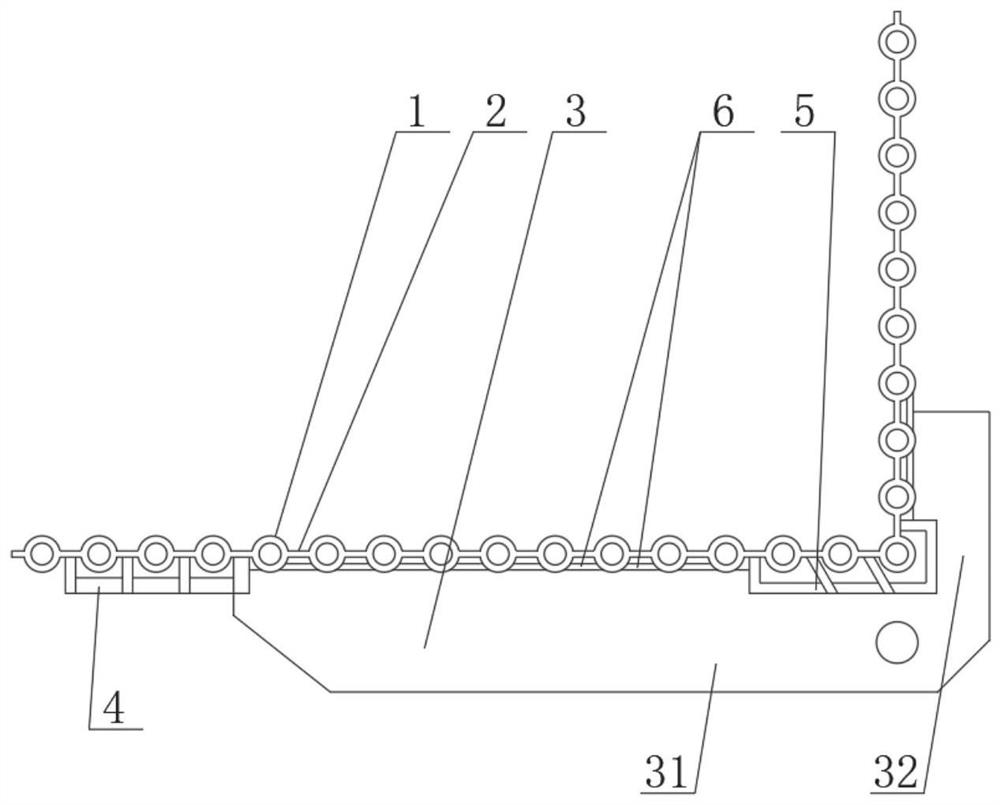

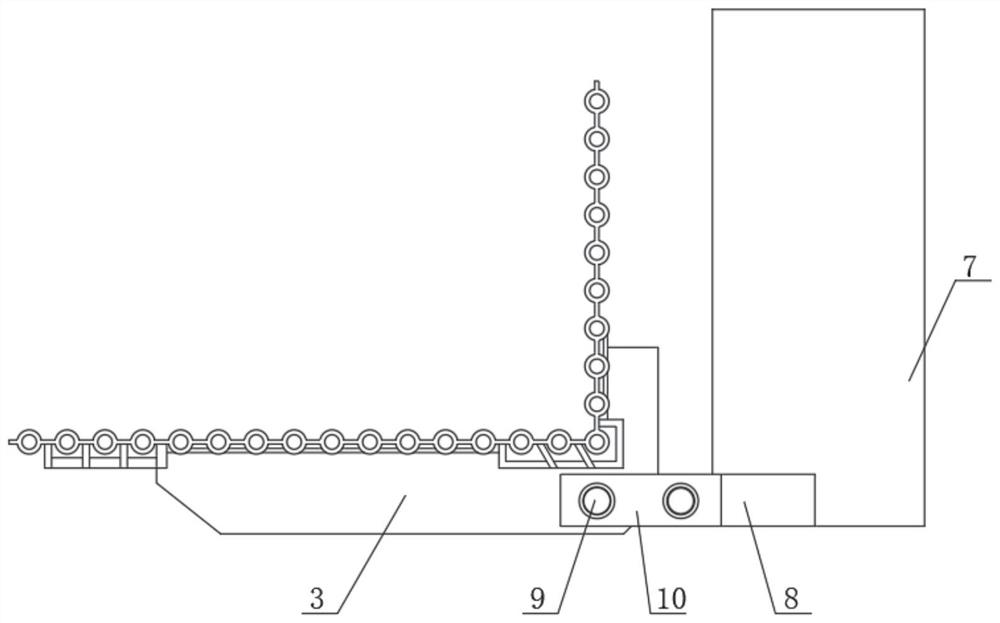

[0021] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , figure 2 As shown, the rigid beam connection device for preventing the failure of the corner of the water wall of the tower supercritical boiler in this embodiment includes the water wall tube 1, the fins 2 connecting the water wall tube 1 to the water wall 11 and the fins 2 for connecting the water wall 11 and the corner plate 3 of the rigid beam 7 in the boiler, the outer surface of the water-cooled wall 11 is connected to the corner plate 3 through at least one guard plate structure, and the guard plate structure is connected to the fins 2 corresponding to the stress concentration position of the water-cooled wall 11, The guard plate structure covers multiple water-cooled wall tubes 1 at the same time, so as to increase the stress-bearing area of the water-cooled wall 11 .

[0023] In the above embodiments, the inne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap