Stretchable arched array friction nanometer power generation fabric and preparation method thereof

A nano-power generation and array technology, applied in the direction of triboelectric generators, chemical instruments and methods, layered products, etc., can solve the problem of low output power of friction nano-power generation fabrics, and achieve stretchable power output and high power output sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

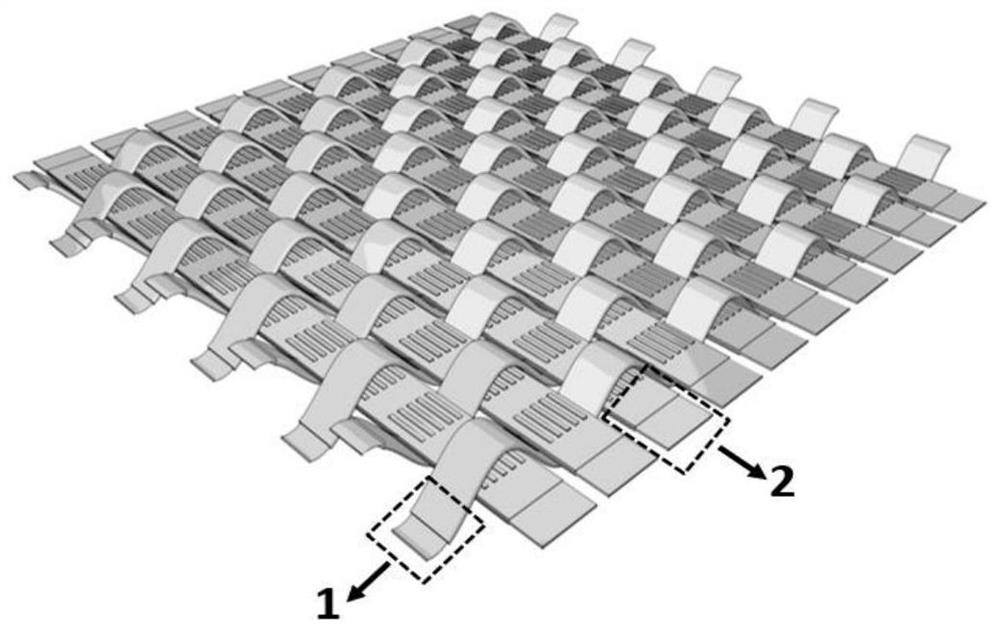

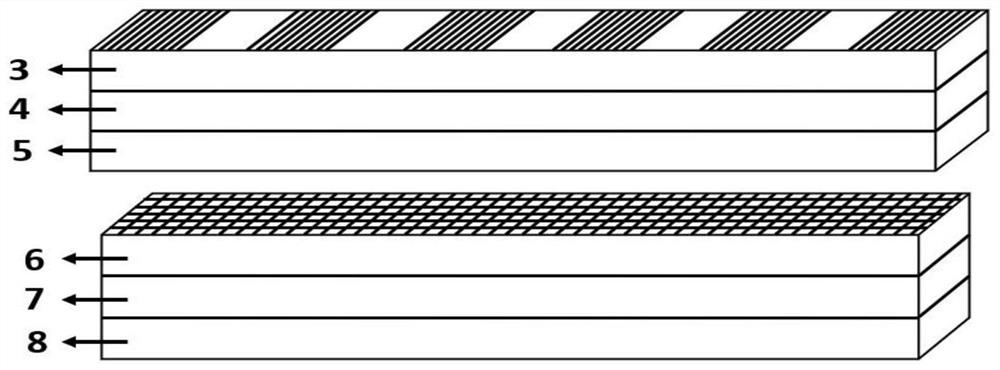

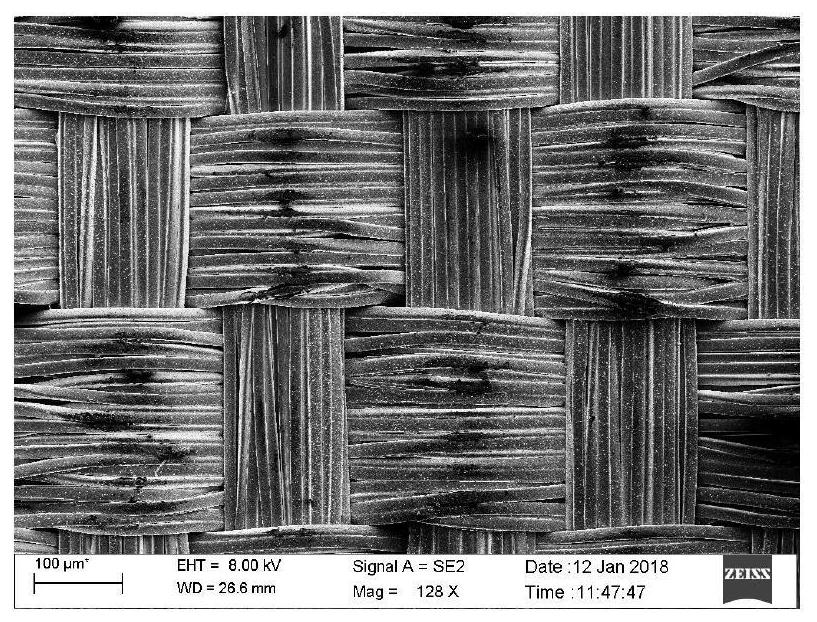

[0040] Stretchable arched array triboelectric nano-generating fabric, the schematic diagram of its structure is shown in figure 1 Said, including horizontal arched array fiber strips A and longitudinal fiber strips B, using traditional horizontal and vertical weaving methods to achieve. The horizontal arched array fiber strip A includes a first conductive layer, a support layer, and a second conductive layer; the longitudinal fiber strip B includes a first polymer layer with a microstructure, a stretchable conductive layer, and a The second polymer layer of the microstructure, the schematic diagram of which is shown in figure 2 shown.

[0041] The preparation method of the stretchable arched array triboelectric nanometer fabric comprises the following steps:

[0042](1) Choose PET material with a thickness of 0.3mm as the supporting layer mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com