Mixed jet descaling system

A descaling system and jet technology, applied in the direction of abrasive jet machine tools, used abrasive processing devices, abrasives, etc., can solve the problem of unable to recycle the medium and reuse it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

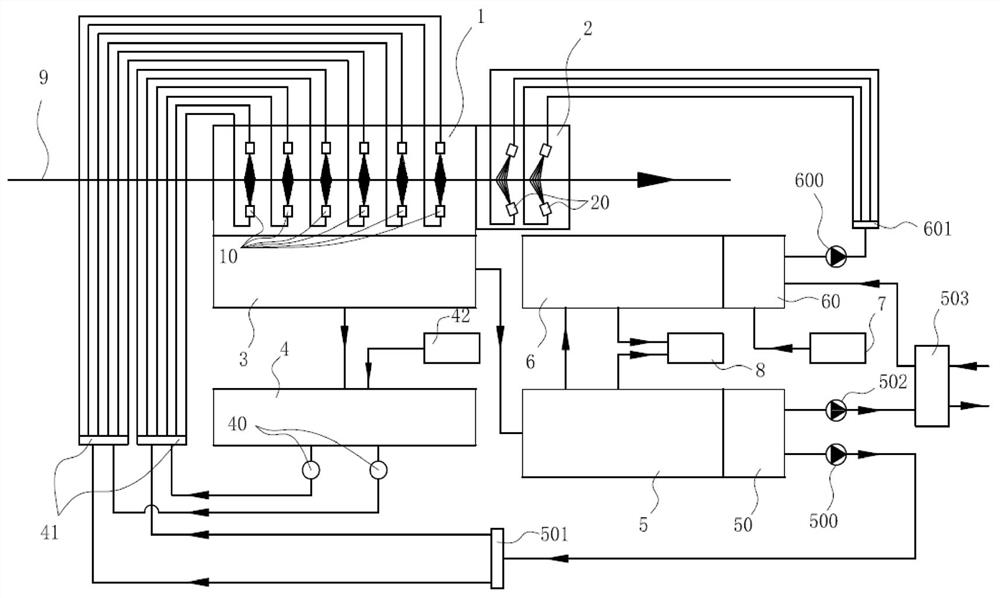

[0031] The mixed jet descaling system includes a spray descaling device and a washing device. The metal strip 9 is conveyed horizontally by the strip conveying device, and passes through the spray descaling device and the washing device in sequence, so as to realize the descaling and cleaning of the metal strip 9 . The strip conveying device is preferably a conveying roller.

[0032] The bottom of the spray descaling device and the flushing device is connected to the collection box 3, and the discharge port of the collection box 3 is connected to the abrasive box 4, and the discharge port of the collection box 3 is provided with a feeder, and the abrasive box 4 is connected to the first abrasive box 4 through the abrasive conveying device 40. A slurry inlet of a distributor 41, the abrasive delivery device 40 is preferably a feeder. The first distributor 41 is provided with two, and the slurry outlet of each first distributor 41 is provided with five, and each slurry outlet is...

Embodiment 2

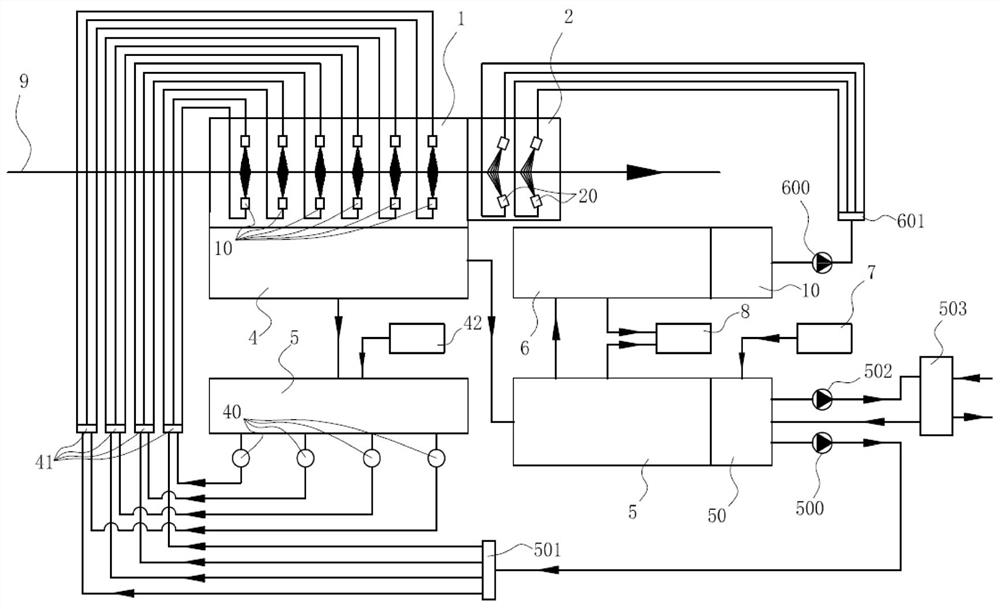

[0046] The difference between this embodiment and Embodiment 1 is that, as figure 2 As shown, the first pool body 50 is connected to the inlet end of the heat exchanger 503 through the third delivery pump 502 , and the outlet end of the heat exchanger 503 is connected to the first pool body 50 . The water in the first pool body 50 continuously enters the heat exchanger 503 for cooling, the cooled water flows back into the first pool body 50, and is cooled by the self-circulation of the first pool body 50, and the cooled water is supplied to The second distributor 501 continues to participate in the circulation system, thereby continuously outputting the heat generated in the entire circulation system to the outside of the system to ensure the energy balance of the entire circulation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com