Thin-wall auxiliary fuel tank assembling device and method

A technology for assembling device and auxiliary fuel tank, which is applied to workpiece clamping device, material gluing, connecting components, etc., can solve the problems of poor adhesive coating quality, redundant structure, reducing the sealing performance of thin-walled auxiliary fuel tank and molding quality, etc. Achieve high axial bonding accuracy, ensure smooth coating, and improve the effect of complex tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The technical problem to be solved in this embodiment is that at present, the assembly process of the auxiliary fuel tank mostly adopts the overall frame and the clamping board assembly process. The end face is coated with adhesive on the spliced end face. Whether the thickness of the adhesive between the spliced end faces is uniform is related to whether the overall structure of the auxiliary fuel tank is stable. When assembling the segmented auxiliary fuel tank body with the existing overall frame and pallet sheet technology, the splicing process is not stable enough, which will easily lead to poor adhesive coating quality, and structural defects will appear after the auxiliary fuel tank is hot-pressed, reducing the The quality of the thin-walled auxiliary fuel tank is improved.

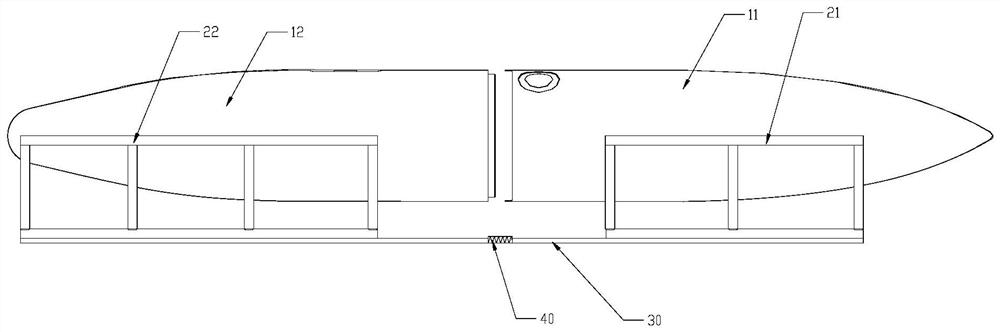

[0039] In order to solve the above technical problems, this embodiment provides a thin-wall auxiliary fuel tank assembly device, such as figure 1 As shown, an assembly platform is inclu...

Embodiment 2

[0046] This embodiment specifically provides a thin-wall auxiliary fuel tank assembly device, such as figure 1 As shown, an assembly platform is included, and a linear slide rail 30 is arranged on the assembly platform;

[0047] The linear slide rail 30 is provided with a first tooling frame 21 and a second tooling frame 22, the first tooling frame 21 and the second tooling frame 22 can translate along the linear slide rail 30, and the first tooling frame 21 uses When loading the front auxiliary oil tank body 11, the second tooling frame 22 is used to load the rear auxiliary oil tank body 12;

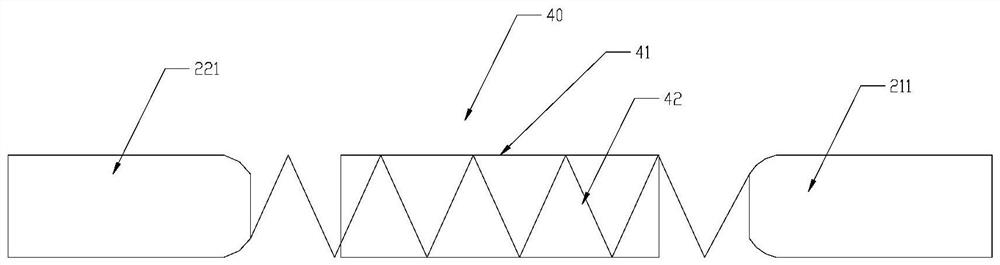

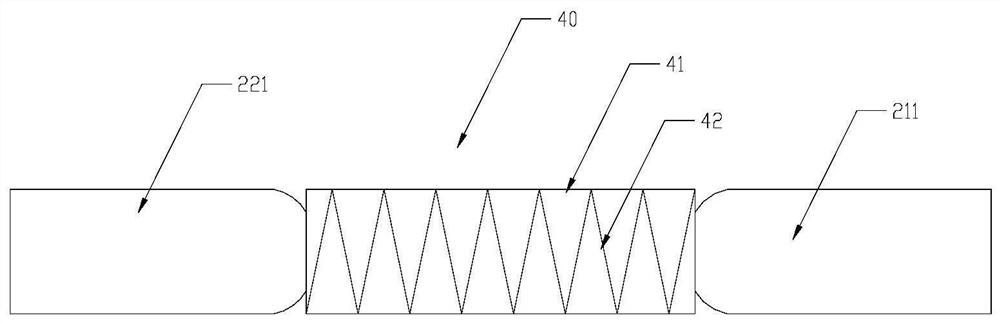

[0048] The first tooling frame 21 is connected to the linear slide rail 30 through the first slide piece 211, the second tooling frame 22 is connected to the linear slide rail 30 through the second slide piece 221, the first slide piece 211 and the The second sliding piece 221 is accommodated in the slideway of the linear slide rail 30 .

[0049] The first tooling frame 21 includes a ...

Embodiment 3

[0063] In order to solve the following technical problems, when assembling the sub-tank body of the segmented sub-tank with the existing overall frame and pallet sheet technology, the splicing process is not stable enough, which will easily lead to poor adhesive coating quality, which occurs after the sub-tank is hot-pressed. Structural defects reduce the quality of thin-walled auxiliary fuel tanks.

[0064] This embodiment provides a thin-wall auxiliary fuel tank assembly method, such as Figure 6 shown, including the following steps:

[0065] S110: setting the linear slide rail 30 on the assembly platform, and setting the first tooling frame 21 and the second tooling frame 22 on the linear slide rail 30;

[0066] S120: Load the front auxiliary oil tank body 11 on the first tooling frame 21, and load the rear auxiliary oil tank body 12 on the second tooling frame 22;

[0067] S130: Assemble a limit buffer device at the middle position of the assembly platform, the limit buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com