Electric meter and processing method thereof

A processing method and technology of electric meters, which are applied in the field of electric meters, can solve the problems of reducing the efficiency of injection molding and single working process of injection molding of electric meter shells, and achieve the effects of improving the accuracy of cooling, increasing the service life, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

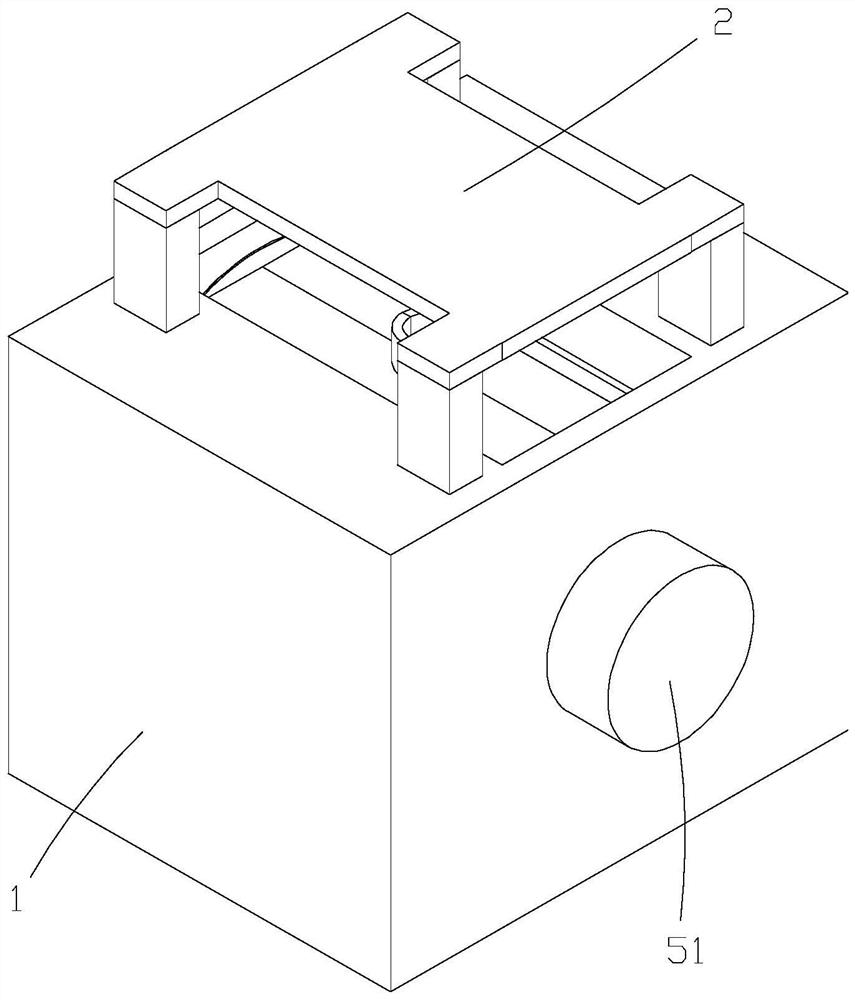

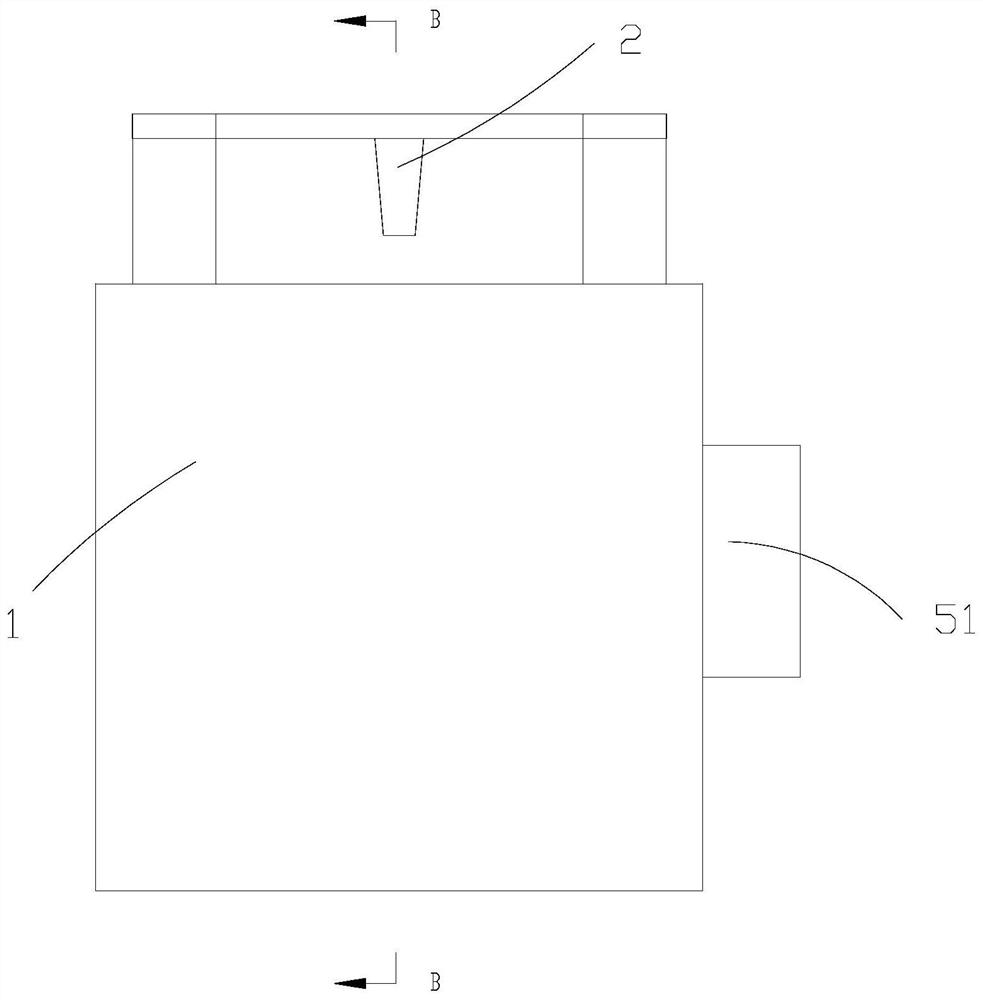

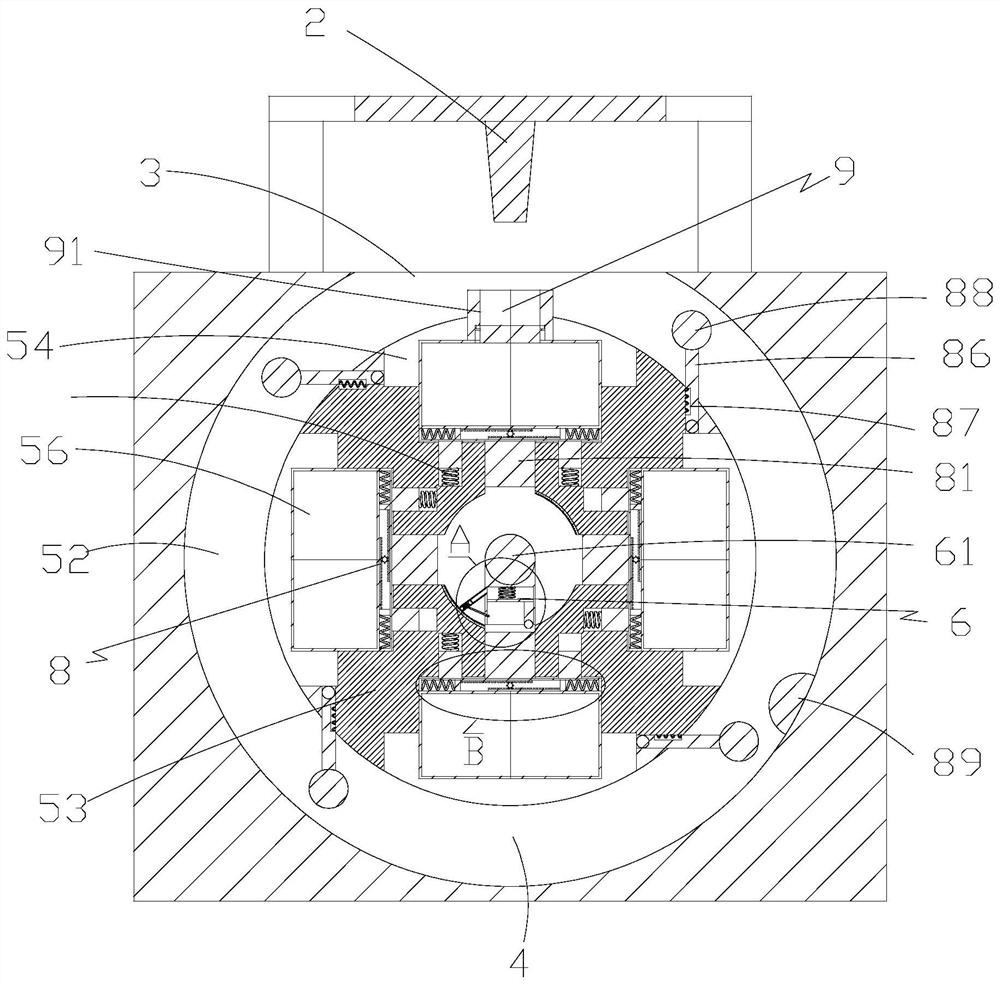

[0030] Such as Figure 1-7 As shown, an electric meter and a processing method thereof, comprising the following steps:

[0031] a. Plasticization: Add plastic to the injection molding machine and heat until it melts;

[0032] b. Injection: inject the plastic in step a into the mold;

[0033] c. Pressure keeping: The pressure keeping is carried out by uniform injection, and the pressure keeping is divided into three stages: the pressure of the first stage keeping pressure is 67kg / cm2 , the holding time is 2s; the second stage holding pressure is 77kg / cm 2 , the pressure holding time is 3s; the pressure of the third stage holding pressure is 86kg / cm 2 , the holding time is 5s;

[0034] d. Cooling and demoulding: demoulding after cooling for 38 seconds;

[0035] Wherein, the injection molding machine in a includes a main body 1, an injection nozzle 2, a working port 3, a discharge port 4, and an injection device 5; the injection device 5 includes a motor 51, an injection cav...

Embodiment 2

[0042] An electric meter and a processing method thereof, comprising the following steps:

[0043] a. Plasticization: Add plastic to the injection molding machine and heat until it melts;

[0044] b. Injection: inject the plastic in step a into the mold;

[0045] c. Pressure keeping: The pressure keeping is carried out by uniform injection, and the pressure keeping is divided into three stages: the pressure of the first stage keeping pressure is 67kg / cm 2 , the holding time is 2s; the second stage holding pressure is 77kg / cm 2 , the pressure holding time is 3s; the pressure of the third stage holding pressure is 105kg / cm 2 , the holding time is 8s;

[0046] d. Cooling and demoulding: demoulding after cooling for 38 seconds;

[0047] Embodiment two

[0048] An electric meter and a processing method thereof, comprising the following steps:

[0049] a. Plasticization: Add plastic to the injection molding machine and heat until it melts;

[0050] b. Injection: inject the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com