a range hood

A range hood and oil fume technology, applied in the direction of removing oil fumes, household stoves/stoves, cleaning methods using liquids, etc., can solve problems such as increased noise, impact on health, waste of energy consumption, etc., to increase noise and improve range hood Effect, the effect of convenient oil scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

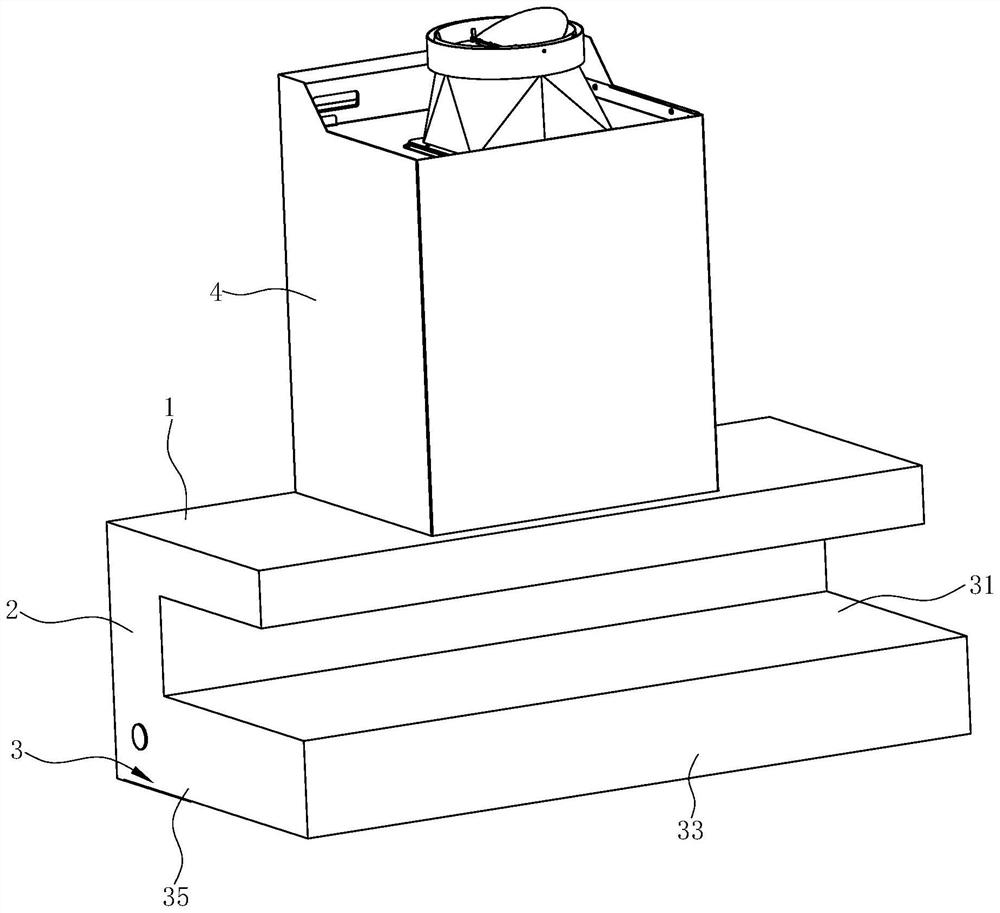

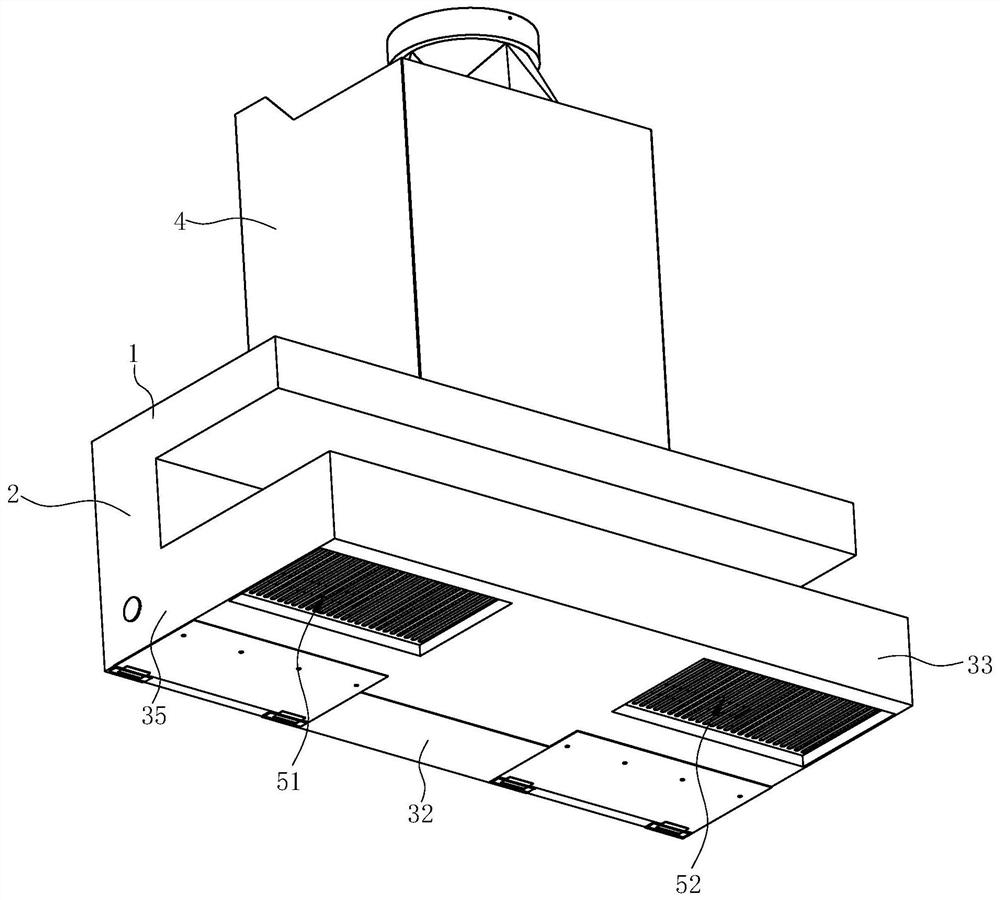

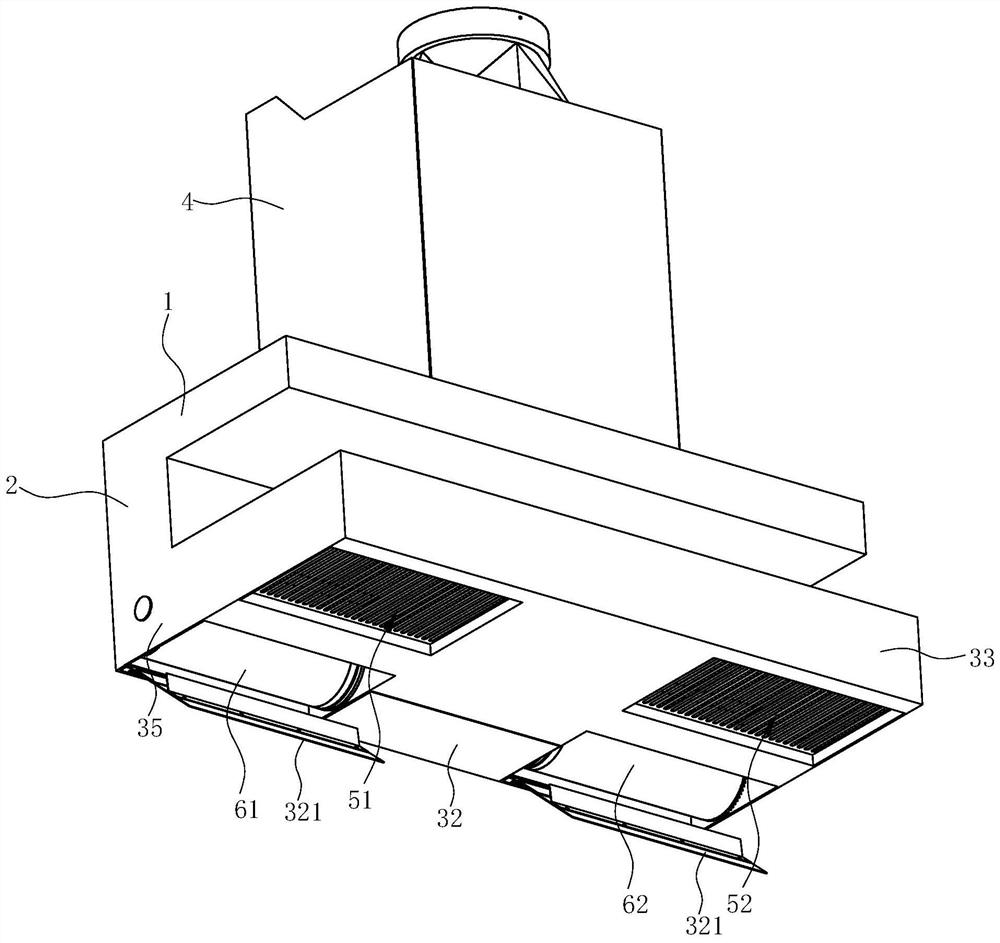

[0046] see Figure 1 to Figure 5 , a range hood, including an upper box body 1, a middle box body 2, a box body structure composed of a lower box body 3, and a fan frame 4, the upper box body 1 is arranged directly below the fan frame 4, and its The length in the left-right direction is larger than the fan frame 4 . The upper box 1 , the middle box 2 and the lower box 3 are all hollow boxes. The bottom of the rear side of the upper box 1 is connected to the top of the middle box 2, the bottom of the middle box 2 is connected to the top of the rear side of the lower box 3, and between the upper box 1 and the middle box 2, the middle box 2 and the lower casing 3 are in fluid communication with each other, and the upper casing 1 and the fan frame 4 are in fluid communication. The size of the upper box 1 and the lower box 3 in the front-rear direction is larger than that of the middle box 2, and the middle box 2 is a box with a thin structure in the front-rear direction, that is...

Embodiment 2

[0066] see Figure 19 , in this embodiment, the difference from the above-mentioned first embodiment is that a self-cleaning device is added outside the first filter 61 and the second filter 62, including a partition plate 71, a heater 72, a water pump 73 and a nozzle 74. Among them, there are three partitions 71, which are respectively connected between the top front side of each filter and the top wall 31 of the lower box 3 (or the front side of the transition box 22), and the top rear side of each filter. and the rear side wall 34 of the lower box 3 (or the rear side of the transition box 22) and between the front and rear sides of the transition box 22, so that a fourth chamber Q4 is formed above each filter for drying Dry. A third chamber Q3 is formed between each filter and the bottom wall 32 and the rear side wall 34 of the lower case 3 for cleaning. The above-mentioned heater 72 is arranged on the top of the fourth chamber Q4, that is, on the side of the uppermost p...

Embodiment 3

[0073] see Figure 20 In this embodiment, the difference from the second embodiment above is that the filter portion 6112 occupies 3 / 4 in the circumferential direction, while the non-filtering portion 6113 occupies 1 / 4 in the circumferential direction.

[0074] The "fluid communication" referred to in the present invention refers to the spatial positional relationship between two parts or parts (hereinafter collectively referred to as the first part and the second part respectively), that is, the energy of a fluid (gas, liquid or a mixture of the two) From the first part to flow along the flow path or / and to be transported to the second part, the first part and the second part can be directly connected, or the first part and the second part can pass through At least one third party is in indirect communication, which may be a fluid channel such as a pipe, channel, conduit, flow guide, hole, slot, etc., or a chamber that allows fluid to flow therethrough, or a combination there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com