Quality detection device for power unit module

A technology of detection device and power unit, which is applied in the direction of measurement device, measurement device casing, automatic disconnection emergency protection device, etc., can solve the problems of hidden safety hazards, low efficiency, and cumbersome quality inspection operations for inspection personnel, and achieves convenient operation. , Not easy to damage, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

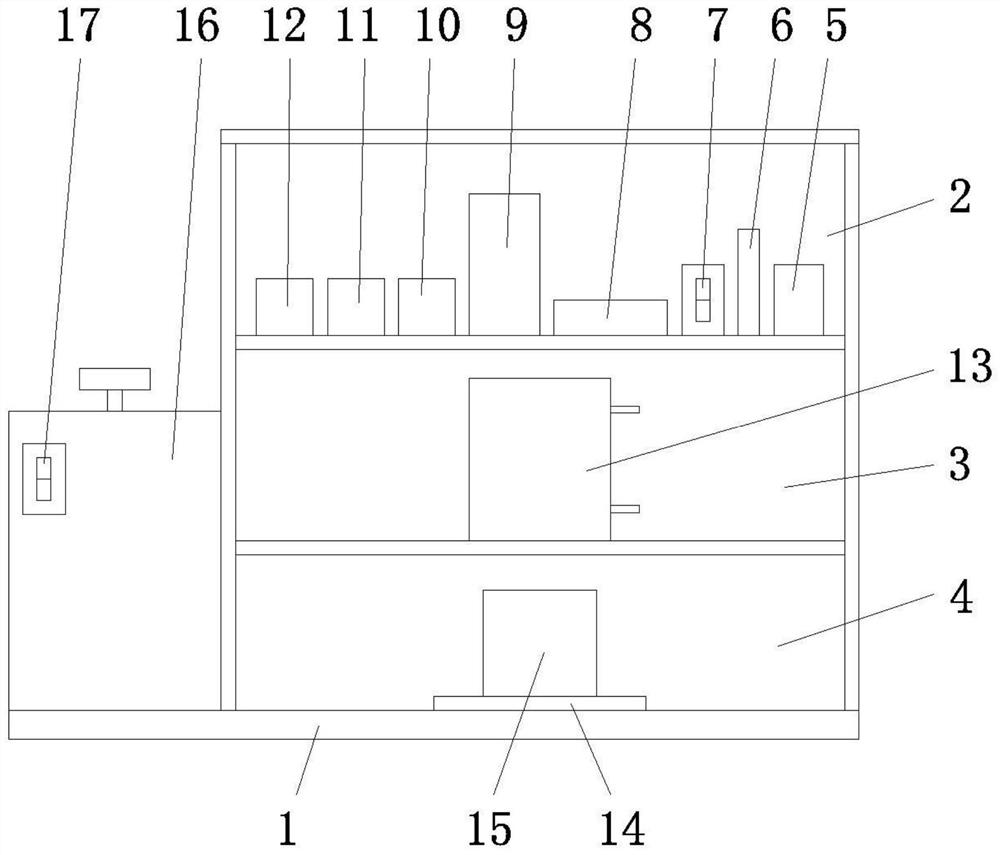

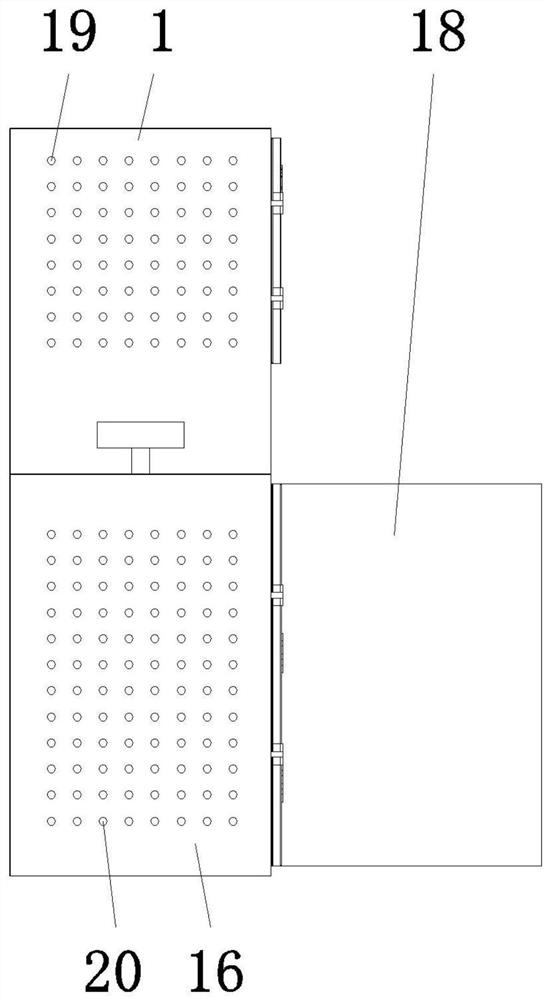

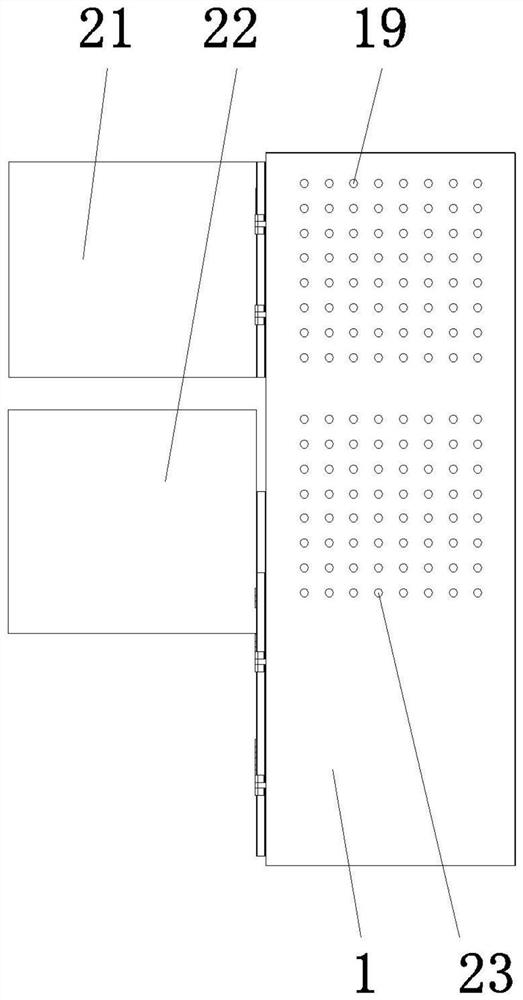

[0023] Such as figure 1 As shown, the present invention includes a detection device body 1, and the detection device body 1 is distributed in the form of a box. The detection device body 1 is sequentially provided with a first equipment layer 2 , a second equipment layer 3 and a detection layer 4 from top to bottom. The detection layer 4 is located at the bottommost position of the detection device body 1 for directly pushing the power unit module 15 to be detected on the cart into the detection layer 4 . The detection layer 4 is provided with a seat plate 14 for placing the power unit module 15 conveniently, and the power unit module 15 is placed on the seat plate 14 . The first equipment layer 2 is provided with an AC voltmeter 12 , a DC voltmeter 11 , an AC ammeter 10 , a transformer 9 , a three-phase rectifier bridge 8 , an outlet circuit breaker 7 , a diode 6 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com