Test method for testing cross interconnection performance of cable on laying site

A cross-connection and cable crossover technology, which is used in the field of cable cross-connection performance inspection on the laying site, can solve the problems of no power supply, inability to implement, and difficult inspection, and achieve the effects of reduced capacity, high intelligence, and strong input compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

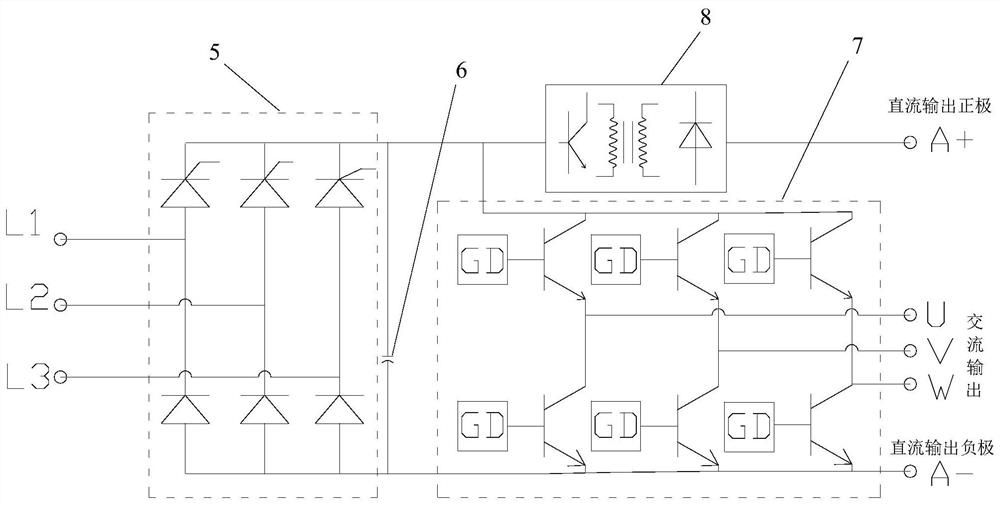

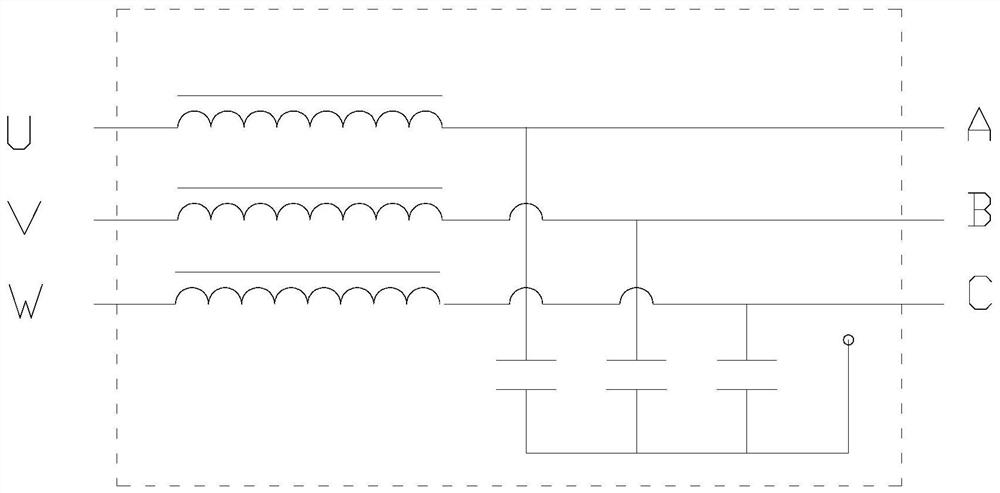

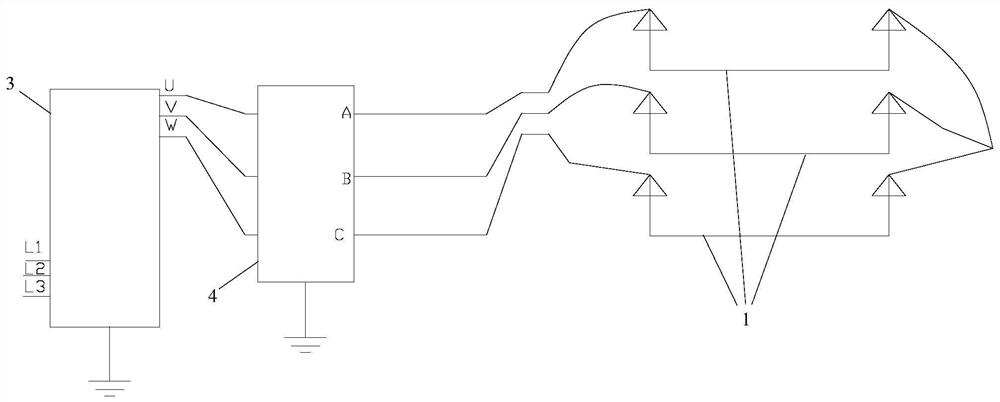

[0051] like Figure 1 to Figure 4 Shown, a kind of test method that the present invention is used for laying on-site cable cross-connection performance inspection is like this: test power supply is set, and this test power supply is used as the power supply of performance test and loop resistance measurement of cable metal sheath cross-connection grounding system;

[0052] The three-phase AC voltage output by the test power supply is applied to the cable core 1 of the cable metal sheath cross-interconnection grounding system with a three-phase power frequency AC current, and the induced voltage and circulating current of the metal sheath in the cable metal sheath cross-interconnection grounding system are measured. Realize on-site laying inspection of the performance of the cable metal sheath cross interconnection grounding system;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com