A kind of preparation method and application of titanium carbide/carbon nano film material

A carbon nano-film, titanium carbide technology, applied in electrochemical generators, active material electrodes, structural parts, etc., to achieve high strength, good conductivity, and improve overall energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

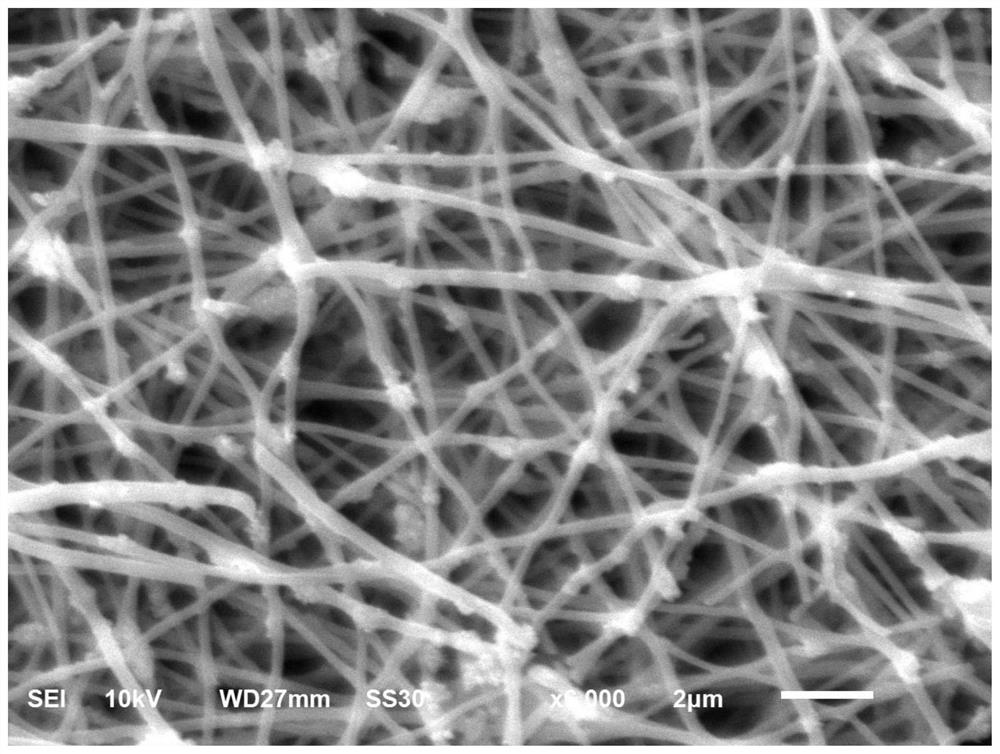

[0028] The method for preparing titanium carbide / carbon nano film material in this embodiment comprises the following steps:

[0029] S1. At 70°C, mix polyacrylonitrile (PAN), polyethylene oxide (PEO), polybenzimidazole (PBI), titanyl sulfate and N,N-dimethylformamide (DMF) according to the mass ratio Mix 3:1:1:6:30 and stir evenly for 12 hours to form a spinning precursor solution; electrospin the spinning precursor solution to obtain a precursor film, place it at 60±5°C for 12 hours in vacuum, and set aside;

[0030] S2. In an air atmosphere, the above-mentioned spinning precursor film is heated to 280°C at a rate of 1°C / min and kept for 2h; under a nitrogen atmosphere, the temperature is raised to 600±50°C at a rate of 2°C / min and kept for 2h to obtain TiO 2 / C nano film material;

[0031] S3, under argon atmosphere, the TiO 2 / C nano-membrane material was heated to 1400°C at a rate of 5°C / min and kept for 6h to obtain titanium carbide / carbon nano-membrane material.

[...

Embodiment 2

[0036] The method for preparing titanium carbide / carbon nanofilm material in this embodiment is basically the same as that in Example 1, except that the mass ratio of PAN, PEO, PBI, titanyl sulfate and DMF in step S1 is 1:1:1:6 :30.

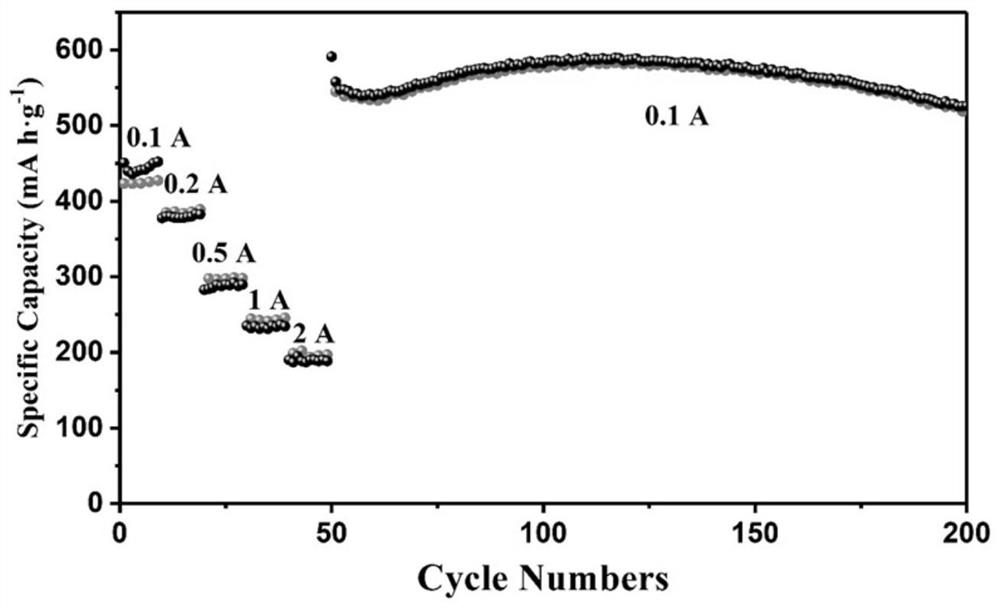

[0037] The titanium carbide / carbon nano-film material prepared according to the method of Example 1 is assembled into a lithium-ion half-cell in a glove box, and the electrical properties of the lithium-ion half-cell are measured, and it is still cycled for 200 cycles at a current density of 0.1A / g. It has a capacity of 490mAh / g.

Embodiment 3

[0039] The method for preparing titanium carbide / carbon nanofilm material in this embodiment is basically the same as that in Example 1, except that the mass ratio of PAN, PEO, PBI, titanyl sulfate and DMF in step S1 is 10:5:5:6 :30.

[0040] The titanium carbide / carbon nano-film material prepared according to the method of Example 1 is assembled into a lithium-ion half-cell in a glove box, and the electrical properties of the lithium-ion half-cell are measured, and it is still cycled for 200 cycles at a current density of 0.1A / g. It has a capacity of 502mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com