Anti-solidification storage device for sealant production based on multi-shaft stirring

A storage device and sealant technology, applied in the field of sealant, can solve the problem of sealant solidification during storage time and affecting the production efficiency of sealant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

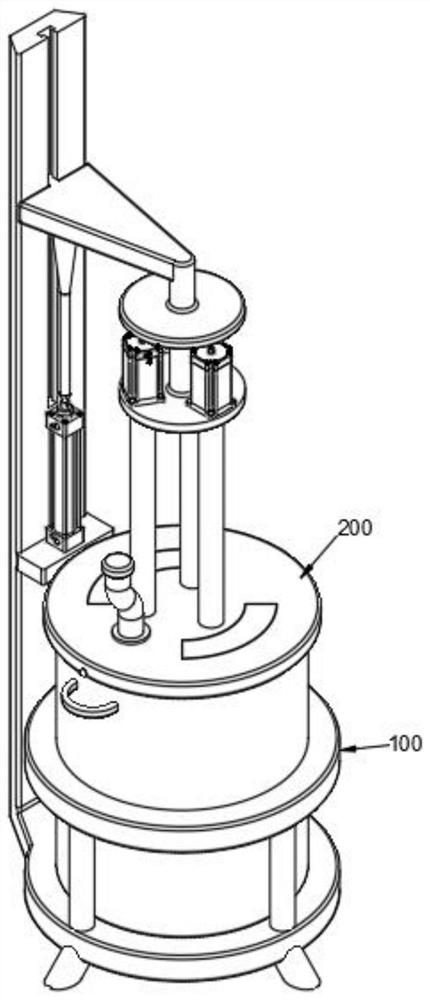

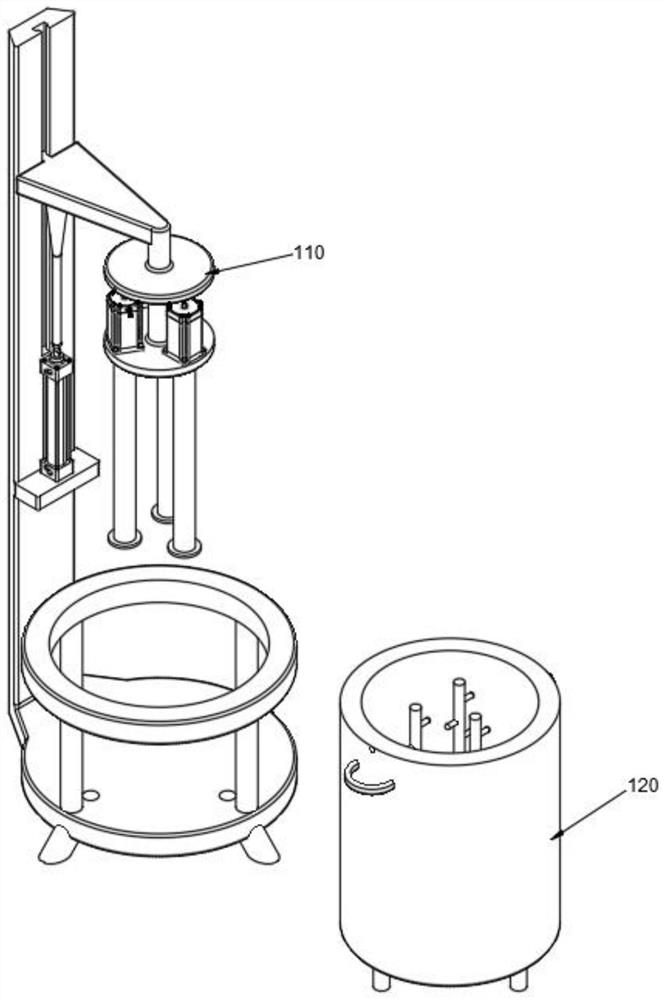

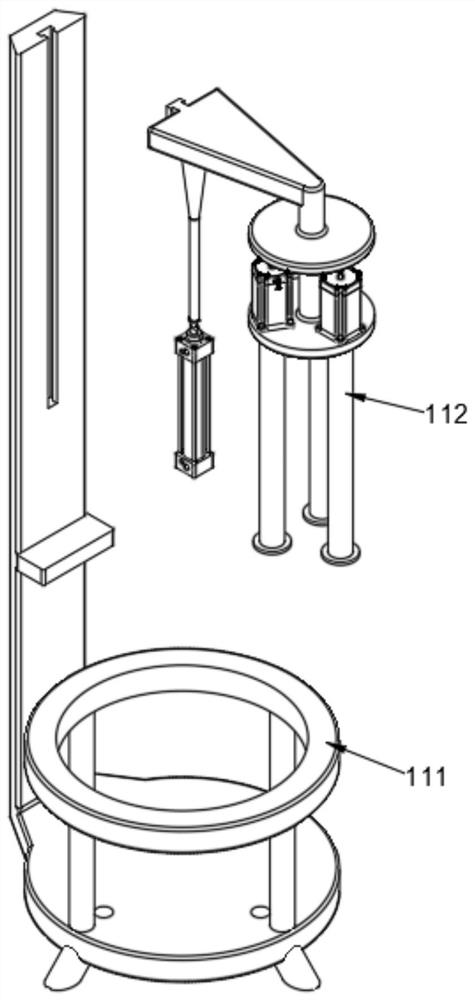

[0044] see Figure 1-Figure 7 As shown, the purpose of this embodiment is to provide an anti-solidification storage device for sealant production based on multi-axis stirring, including a stirring storage body 100, and the stirring storage body 100 includes at least:

[0045] The sealant mixing body 110, the sealant mixing body 110 includes a fixed body 111, the bottom of the fixed body 111 is provided with a foot pad 113, the top of the fixed body 111 is provided with a fixed ring 114, and the fixed body 111 is provided with a vertical frame 115, vertical Frame 115 is connected with stirrer 112, and stirrer 112 comprises the connection frame 116 that is connected with vertical frame 115, and the bottom of connection frame 116 is connected with installation body 117, and installation body 117 comprises the fixed plate 1171 that is connected with connection frame 116, and fixed plate The surface bolts of 1171 are fixed with three servo motors 118, the bottom of the servo motor ...

Embodiment 2

[0053] see Figure 8-Figure 10 As shown, in order to avoid mixing impurities while ensuring that the sealant is stirred to prevent solidification, the following improvements are made on the basis of Example 1:

[0054] Wherein, the top of the storage tank 121 is provided with a sealing body 200, the sealing body 200 at least includes a sealing plate 210, the sealing plate 210 includes a cover plate 211, and the cover plate 211 is provided with three transmission ports 212 penetrating through its surface, and the transmission ports 212 are circular. The transmission shaft 1181 passes through the transmission port 212, and the bottom of the cover plate 211 is provided with an insertion groove 213. The insertion groove 213 is a ring-shaped groove, and the insertion groove 213 is plugged and matched with the storage tank 121. The storage tank 121 and the socket slot 213 can ensure the tight connection between the sealing plate 210 and the storage body 120 to avoid leakage of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com