An energy-saving crusher for cement production

A cement preparation and energy-saving technology, which is applied in cement production, clinker production, grain processing, etc., can solve problems such as damage to the crusher, excessive force on the device, and impact on the service life of the device, so as to reduce the degree of force, Guarantee the service life and improve the crushing effect

Active Publication Date: 2022-06-03

涞水县永乐水泥制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the process of cement production and processing, although the existing crushers can effectively crush the cement raw materials, because the crushing method is to crush the raw materials through the crushing machine's own strength, although this method can crush the cement raw materials. Crushing, but because the device is often subjected to excessive force during the crushing process, it is easy to cause damage to the crusher itself and affect the service life of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

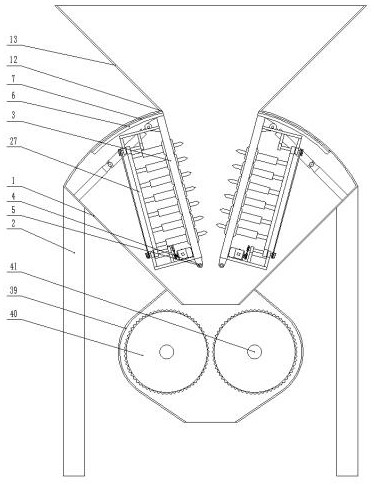

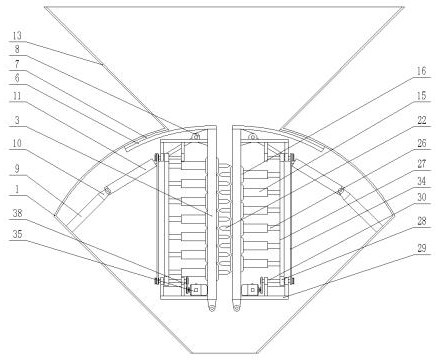

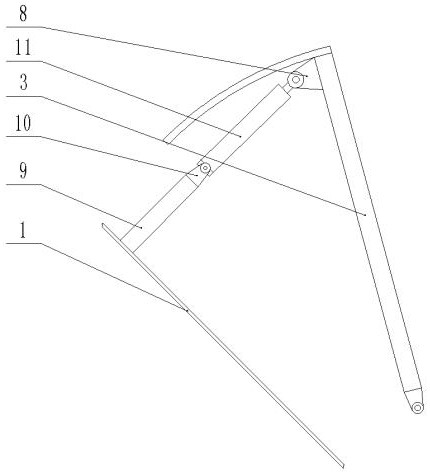

The invention discloses an energy-saving crusher for cement production, which comprises a box body and brackets installed at both ends below the box body. A secondary crushing device is arranged under the box body. A crushing device, the reciprocating crushing device is equipped with an electric hammer crushing cone device. In the present invention, through the adjustment of the angles of the two extruded crushing plates, the device can crush large raw materials; through the use of the hammering sleeve, the hammering piston can pass through the action of air pressure during the raw material crushing process of the crushing cone. The reciprocating hammer crushing cone mounting seat improves the crushing efficiency, and at the same time avoids direct high-strength extrusion of raw materials, thereby reducing the degree of stress on the device and avoiding damage to the device due to excessive force; through secondary crushing of raw materials Secondary crushing is carried out, so that small pieces of raw materials can be completely crushed, so as to improve the use of the crushing device and achieve the best crushing effect.

Description

An energy-saving crusher for cement preparation and production technical field The present invention relates to the relevant equipment field of cement production and processing, particularly a kind of energy-saving cement preparation and production crusher machine. Background technique [0002] With the vigorous development of the construction industry, the development of the building materials market has been greatly driven. There are many kinds of building materials, but one of cement It is the most basic and important building material. There are special production lines for the production and processing of cement. Cement production line is the production The cement equipment production line is composed of a series of equipment for cement, mainly composed of crushing and pre-homogenization, raw meal preparation homogenization, preheating It is composed of processes such as solution, cement clinker sintering, cement grinding and packaging. Portland cement product...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B02C21/00B02C1/04B02C1/10B02C4/08

CPCB02C21/00B02C1/005B02C1/043B02C1/10B02C4/08Y02P40/121

Inventor 王安琪

Owner 涞水县永乐水泥制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com