Energy-saving crusher for cement preparation and production

A cement preparation and energy-saving technology, which is applied in cement production, clinker production, grain processing, etc., can solve the problems of crusher damage, affecting the service life of the device, and excessive force on the device, so as to reduce the degree of force, Improve the crushing effect and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

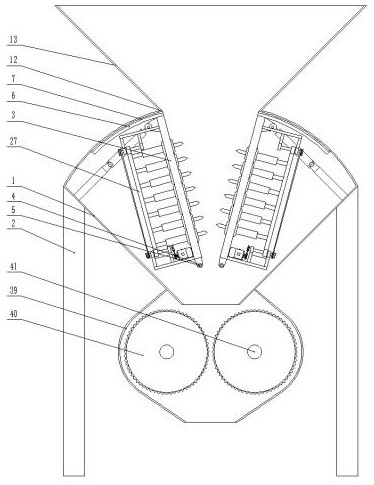

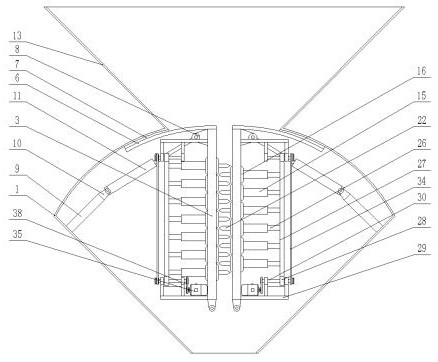

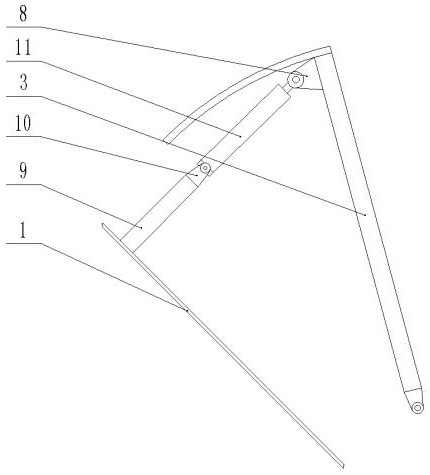

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-9 shown.

[0031] In this device, the device is powered by connecting to an external power supply, and the external power supply is electrically connected to the electric automatic reciprocating cylinder 11, the high-speed drive motor 35 and the crushing motor 45 through a control switch, thereby controlling the operation of the entire device.

[0032] The creative point of this scheme lies in the structural design of the reciprocating extrusion crushing device, combined with the figure 1 , attached figure 2 And attached image 3, the reciprocating extrusion crushing device includes two extrusion crushing plates 3, the two extrusion crushing plates 3 are located on both sides of the center of the box body 1, the two ends of the lower surface of the extrusion crushing plate 3 are installed with adjustment bearings 4, and the adjustment bearings 4 It is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com