Method for Improving Load Response Rate of Generating Units in Medium-Speed Coal Pulverization System

A technology for generating sets and machine powder, applied in grain processing and other directions, can solve the problems of slow boiler load response rate, affecting the grid load response rate of the generator set, and difficulty in reaching the grid load response rate, etc. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

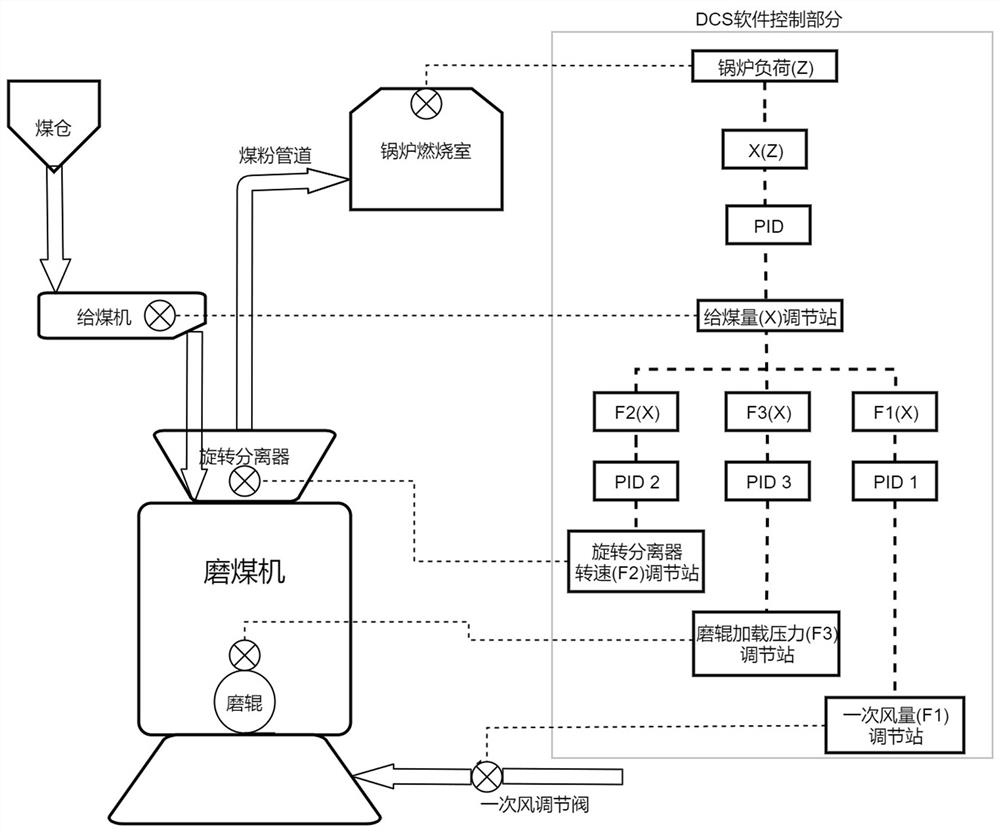

[0022] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] The present invention is a method for improving the response load rate of a generator set of a medium-speed coal mill pulverization system, comprising the following steps:

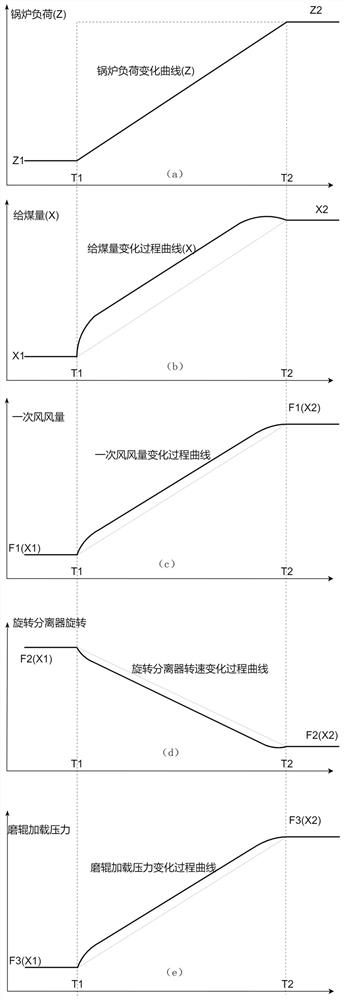

[0024] S1. Assuming that the grid load demand is Q1 at time T1, and the demand at time T2 is Q2, the DCS of the medium-speed pulverized coal pulverizing system responds to the grid load demand and releases the boiler combustion chamber load Z. At this time, the boiler of the medium-speed pulverizing pulverization system burns The chamber needs to rise from Z1 at time T1 to Z2 at time T2, and the boiler load change rate is (Z2-Z1) / (T2-T1). Corresponding to the amount of coal fed X, the calculation formula is as follows:

[0025] X(Z)=a*(kZ+i) +b[(Z2-Z1) / (T2-T1)]

[0026] k, i are fitting constants, determined by experiments, a is the correction coefficient of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com