Control method for fast variable load of heat and power cogeneration units based on heat and power load conversion model

A heat and power cogeneration unit and load control technology, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve problems such as difficult to achieve automatic power generation control of the power grid, improve load response rate, ensure heat supply quality, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

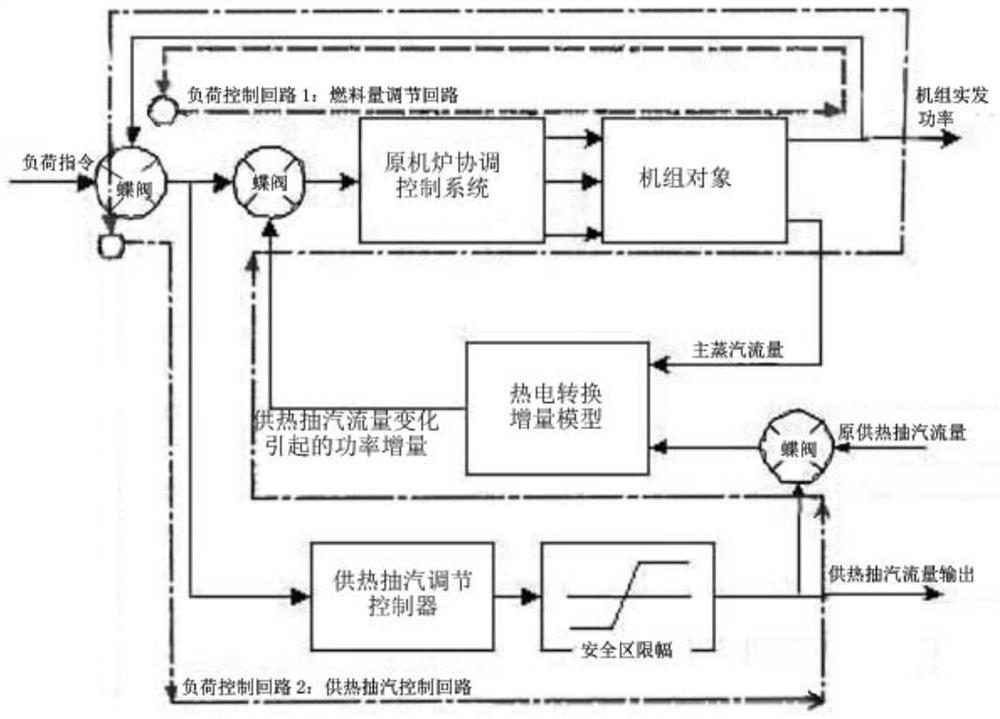

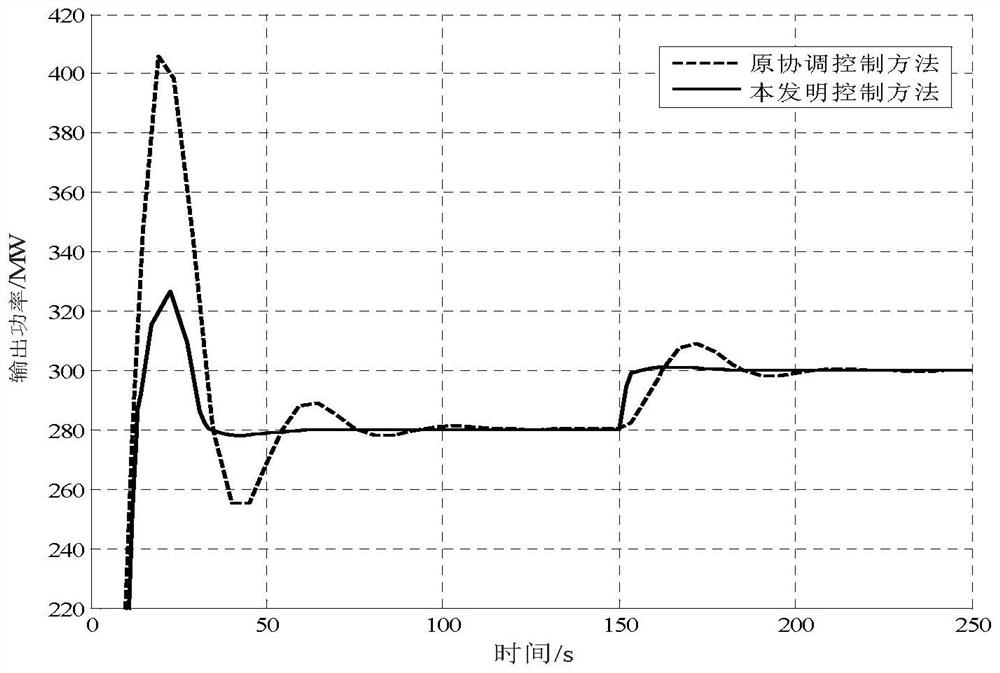

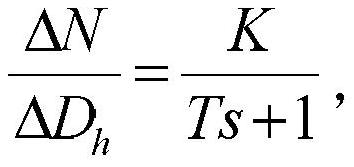

[0030] Taking a 330MW cogeneration unit as an example, the characteristic model of the influence of the change of heating and extraction steam flow rate on the unit load change is described by the first-order inertial link:

[0031]

[0032] In the formula, ΔN is the unit load variation; ΔD h is the variation of heating and extraction steam; K is the proportional gain, which can be calculated by using the static characteristics of thermoelectric coupling to calculate the difference before and after the output power caused by the increase of heating and extraction steam flow, and its ratio is the proportional gain K. For example, a 330MW unit provides Under the TMCR working condition, the power generation output of the unit with heat supply and steam extraction of 0 and 300t / h is 348.48MW and 306.93MW respectively. At this time, the proportional gain of the unit can be directly obtained K=(306.93—348.48) / (300 —0)=—0.1385, this value is slightly different under different load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com