Blade air inlet and outlet edge six-axis electric spark machining machine tool

A technology of intake and exhaust edges and processing machine tools, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of easy assembly, easy processing and assembly, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0017] The invention relates to a six-axis electric discharge machining machine tool for blade intake and exhaust edges, which is used to solve the difficult problem of complex curved surfaces at the intake and exhaust edges of engine blades.

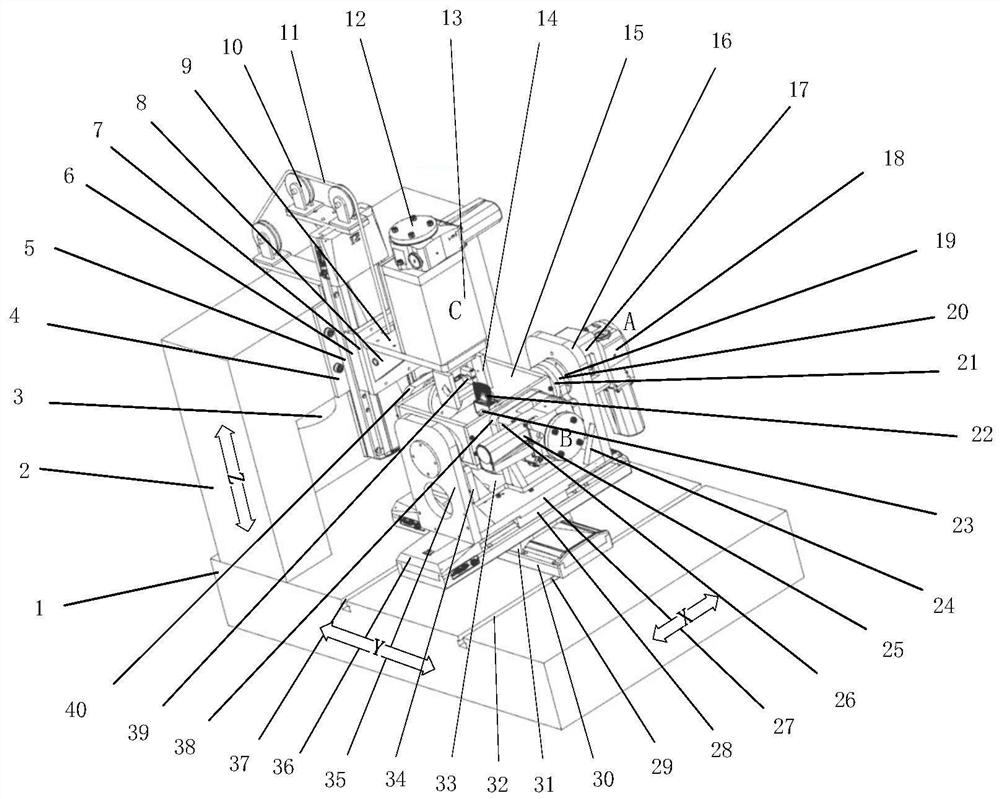

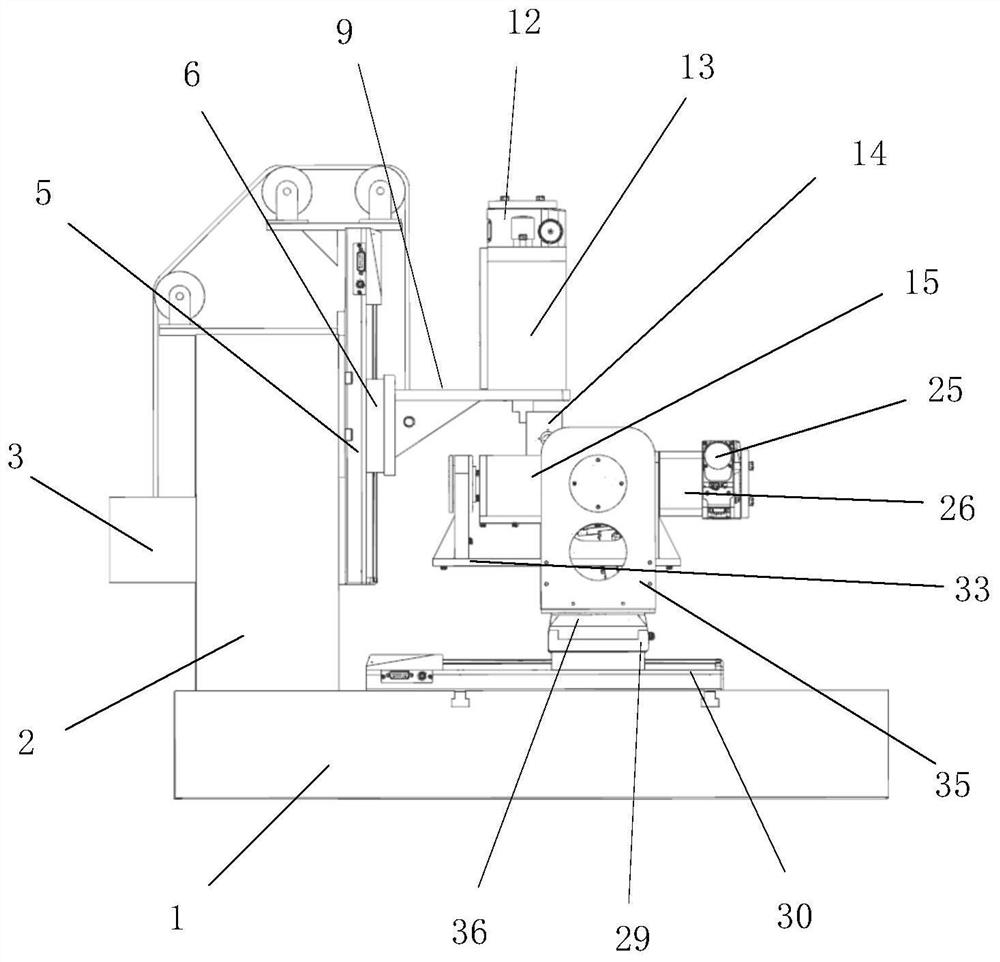

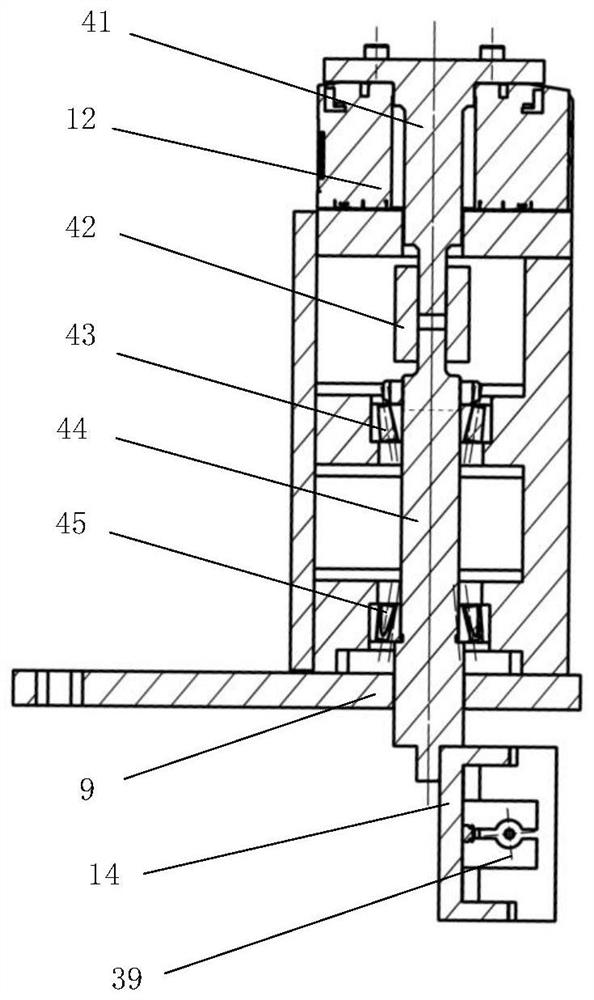

[0018] The six-axis EDM machine tool includes bed, XYZ linear movement mechanism, ABC rotation mechanism, AB direction double cradle mechanism, C direction rotation mechanism, forming electrode and electrode clamping mechanism, engine blade clamping mechanism, C direction rotation axis and counterweight mechanism.

[0019] Steps to build the machine tool: First, fix the Y-direction linear moving axis 30 on the horizontal plane of the bed through the first bed positioning groove 32, the second bed dovetail groove 37 and connecting screws, and then connect the X-direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com