Lanthanum crown optical glass, preparation method thereof and optical element

A technology for optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems that are not conducive to the stable production and control of optical glass, high-definition vehicle lenses, glass coloring, etc., and achieve chemical stability and mechanical stability. Excellent performance, simple and easy preparation method, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The present application also provides a method for preparing lanthanum crown optical glass with a negative refractive index temperature coefficient according to the present application, including: weighing each component according to the proportion, mixing them uniformly, and then melting them, and then casting or pouring them into a molding mold , or direct compression molding.

[0089] Specifically, each component is weighed and mixed uniformly according to the specified ratio to make a batch, and the prepared batch is put into a smelting device made of quartz, corundum or precious metal (Au, Pt, etc.), It is melted, stirred, and clarified at a temperature of 1200-1450°C, and poured or leaked into a molding mold for molding, or directly pressed for molding, and finally annealed and cooled to obtain the optical glass or optical element of the present application.

[0090] The present invention also provides an optical element comprising the lanthanum crown optical glas...

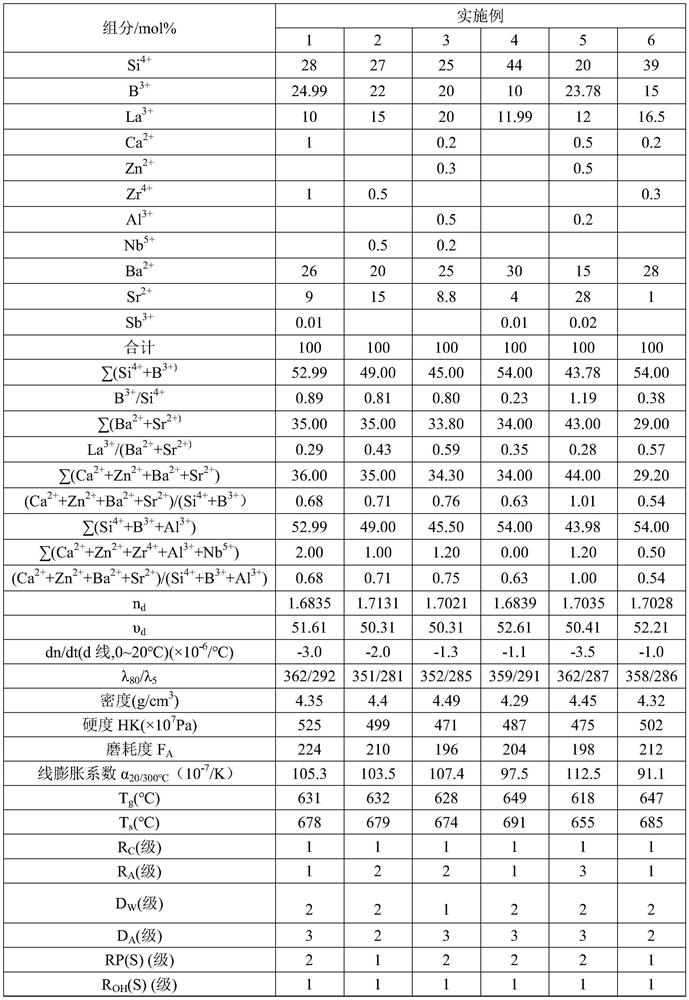

Embodiment 1-40

[0094] The components of Examples 1-40 in Tables 1-7 are weighed in proportion and mixed uniformly to make a batch, and the prepared batch is put into a crucible made of precious metal Pt, at a temperature of 1200-1450°C After 20 hours of melting, stirring, and clarification, the temperature was lowered to 1200°C for 1 hour, and then released from the furnace, leaked into the mold for molding, and the optical glass of the present application could be obtained after the glass was annealed and cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com