Mutant strain for increasing content of ethanol produced by fermentation of synthesis gas and application of mutant strain

A mutant strain and ethanol production technology, which is applied in the biological field to achieve the effects of optimizing fermentation conditions, increasing proportion and increasing ethanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

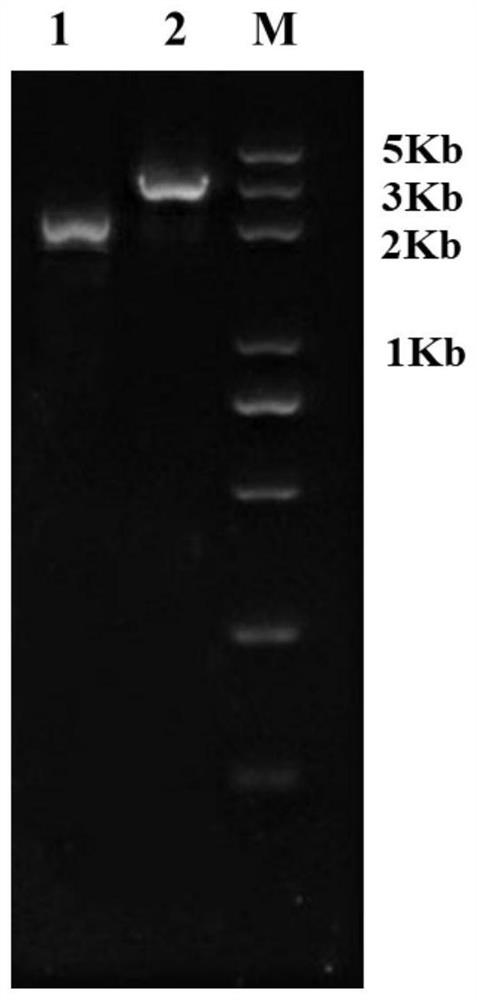

[0074] Example 1: Construction of Clostridium yondhal DSM 13528 2,3-butanediol dehydrogenase deletion mutant 1. Construction of gene knockout plasmid

[0075]Use restriction endonucleases SalI and XhoI to double digest the plasmid pMTLcas-pta, recover the 9000bp long fragment, and obtain the linearized pMTLcas vector backbone;

[0076] Design a guide RNA targeting the 20nt target region of the CLJU_c23220 gene (2,3-butanediol dehydrogenase) in Clostridium yondhal DSM 13528. The gene sequence is shown in Gene ID: 45179669, and then use pMTLcas-pta as a template, sgRNA -F / sgRNA-R is a primer, and the sgRNA scaffold is obtained by polymerase chain reaction (PCR).

[0077] The polymerase chain reaction system was 50 μl (2×KAPA Mix, 25 μl; 1 μL each of sgRNA-F / sgRNA-R (10 μM), 1 μL (50 ng) of pMTLcas-pta carrier, added water to make up to 50 μl).

[0078] PCR amplification conditions, ①pre-denaturation at 95°C for 3 min, ②denaturation at 98°C for 20 sec, ③annealing at 60°C for 20 ...

Embodiment 2

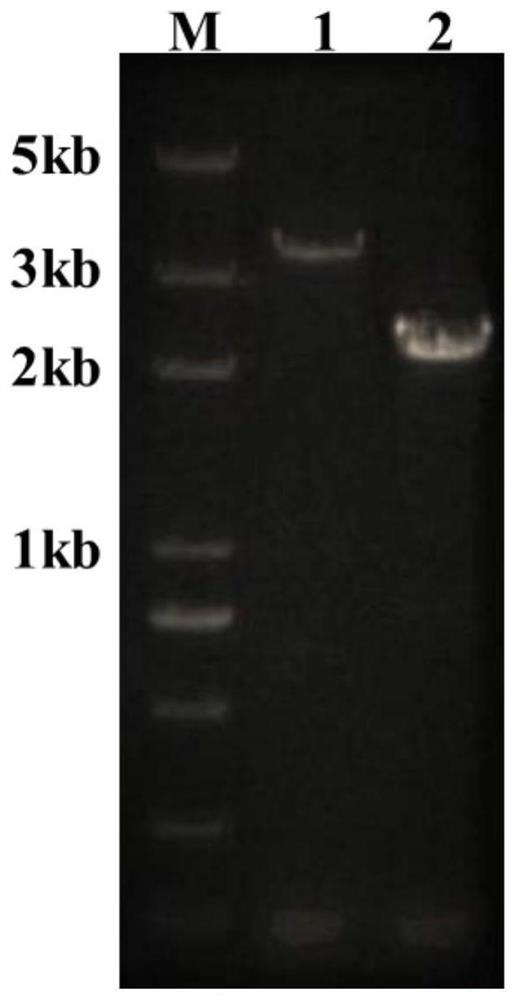

[0104] Example 2: Construction of 2,3-butanediol dehydrogenase deletion mutant of Clostridium ethanologenum DSM 10061 1. Construction of gene knockout plasmid

[0105] Use restriction endonucleases SalI and XhoI to double digest the plasmid pMTLcas-pta to obtain the linearized pMTLcas vector fragment;

[0106] Using pMTLcas-pta as a template and sgRNA-F / sgRNA-R as primers, sgRNA was obtained by polymerase chain reaction (PCR), targeting the 20nt target region of the gene of Clostridium ethanogenum DSM 10061CAETHG_0385, the gene sequence is as Gene ID: 33107402 shown;

[0107] Genomic DNA of Clostridium ethanogenum DSM 10061 was used as a template, HA-upstream-F / HA-upstream-R and HA-downstream-F / HA-downstream-R were used as primers, respectively, and the open reader located at CAETHG_0385 was obtained by polymerase chain reaction Two homology arms (HA-upstream and HA-downstream) on both sides of the box;

[0108] By overlapping extension PCR, HA-upstream and HA-downstream wer...

Embodiment 3

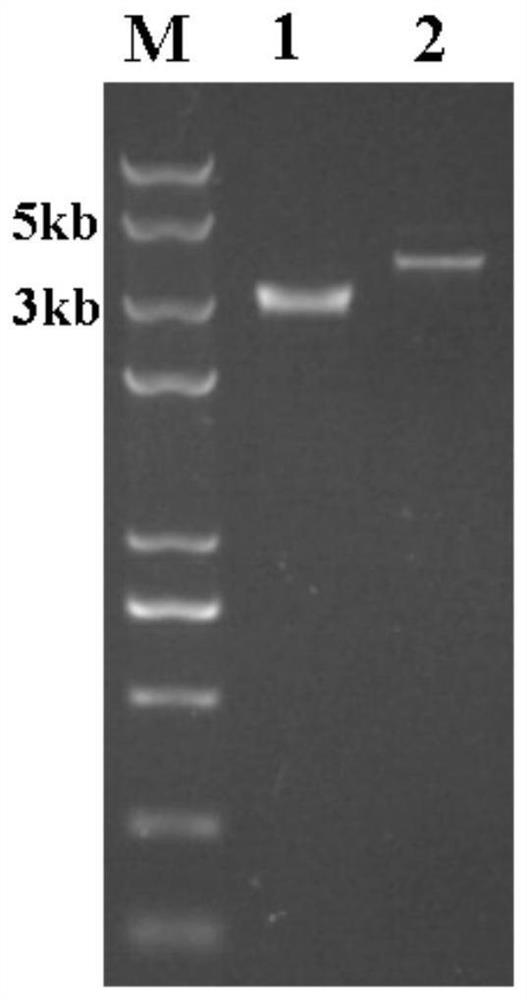

[0116] Example 3: Construction of Clostridium yondhal DSM 13528 pyruvate decarboxylase gene instead of 2,3-butanediol dehydrogenase gene expression mutant

[0117] 1. Construction of gene replacement plasmid

[0118]Pyruvate decarboxylase converts pyruvate to acetaldehyde. Specifically, the pyruvate decarboxylase gene is from Zymomonas mobilis subsp. mobilis ATCC 29191.

[0119] In order to optimize the heterologous expression of the pyruvate decarboxylase gene (CP003704.1:1958606-1960312; Locus tag: ZZ6_1712) derived from Zymomonas mobilis, according to the preferred codons of the host Clostridium yondhal DSM 13528, Codon optimization was carried out on the pyruvate deacidase gene (codon optimization was entrusted to Huada Genomics Co., Ltd.), and the optimized gene sequence was synthesized, see SEQID NO.1 for details.

[0120] Use restriction endonucleases SalI and XhoI to double digest the plasmid pMTLcas-pta to obtain a linearized 9000bp pMTLcas vector backbone;

[0121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com