Patents

Literature

32 results about "Butanediol dehydrogenase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

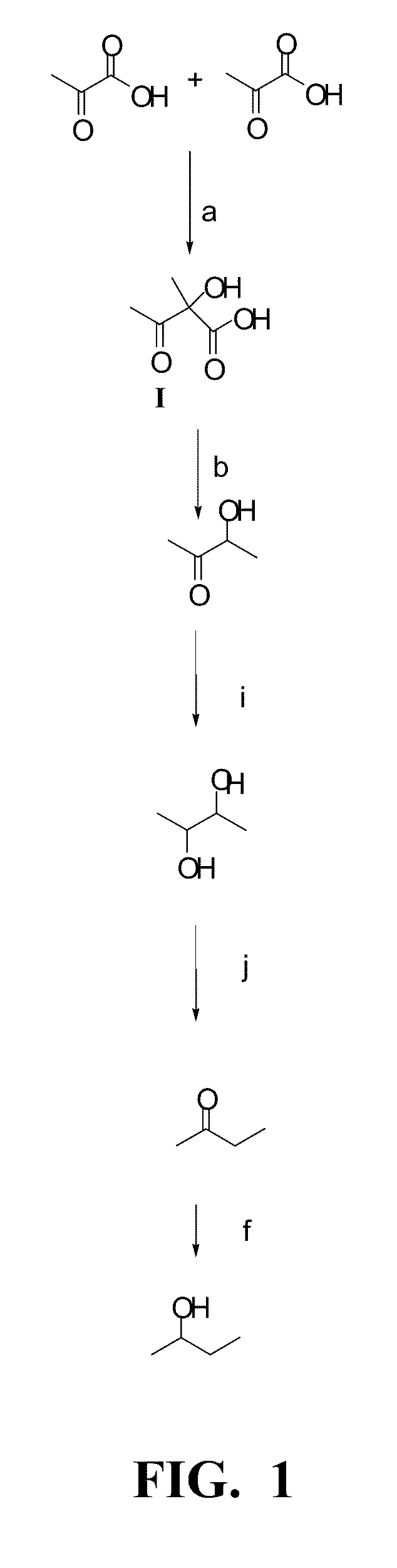

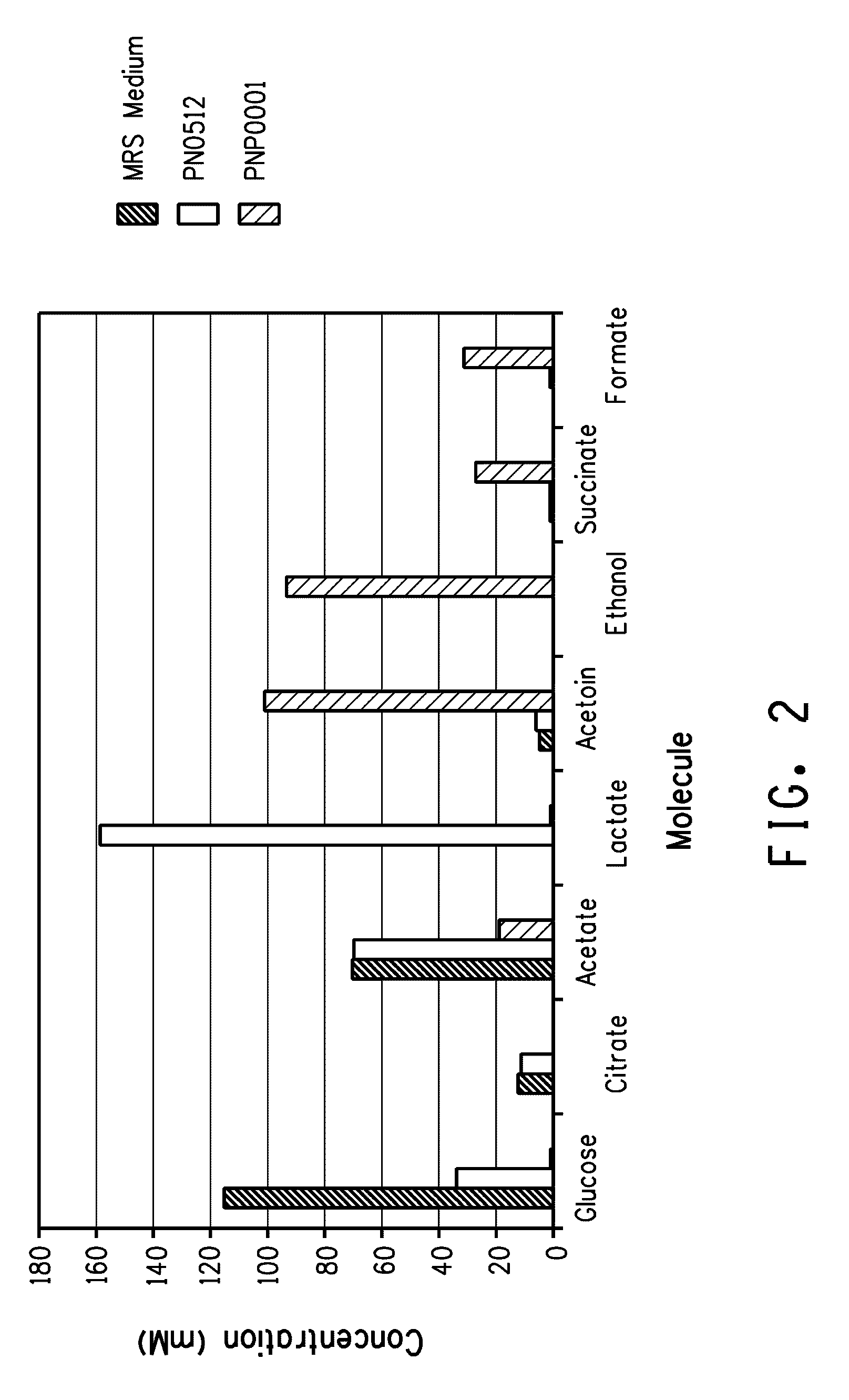

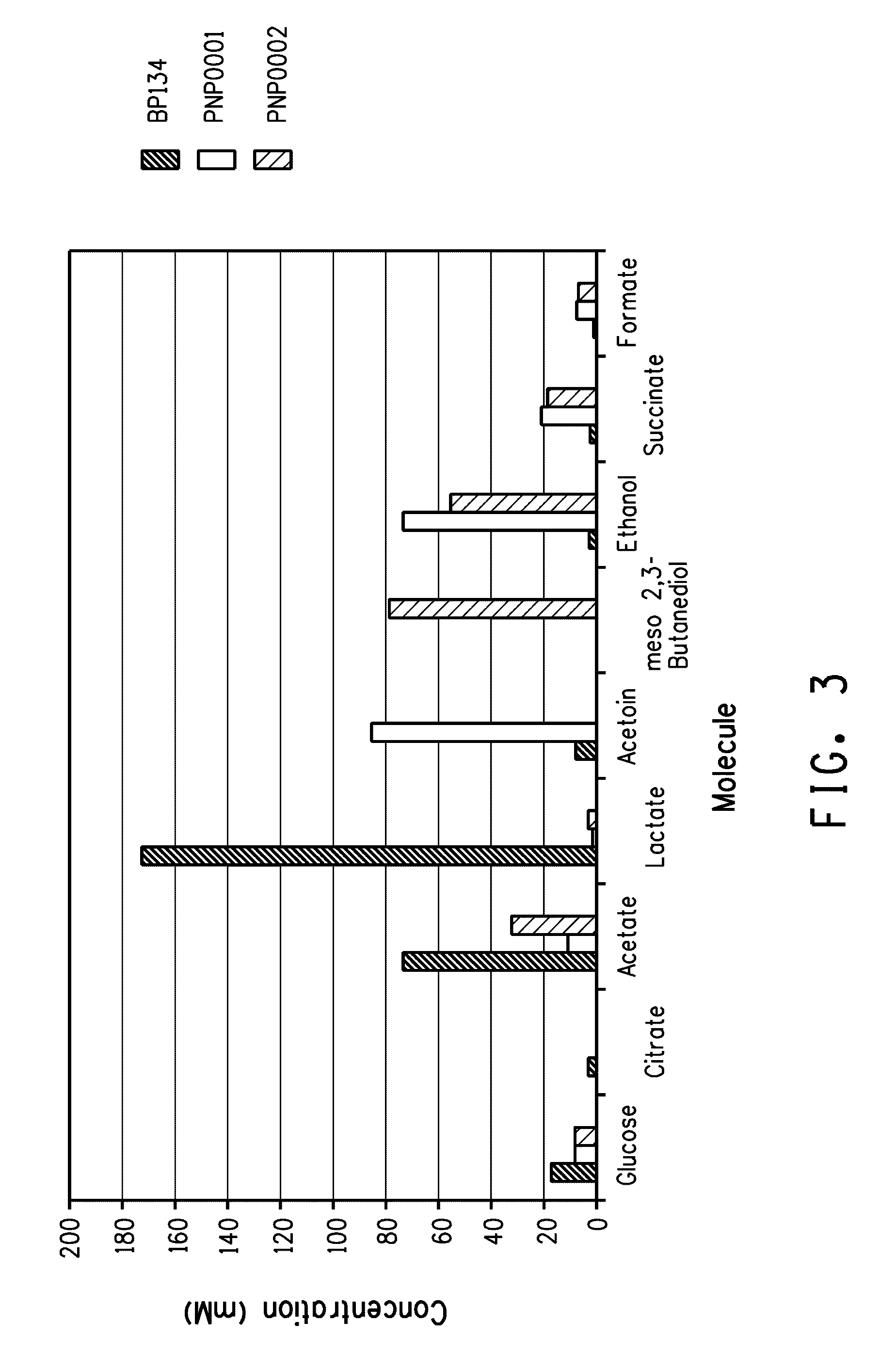

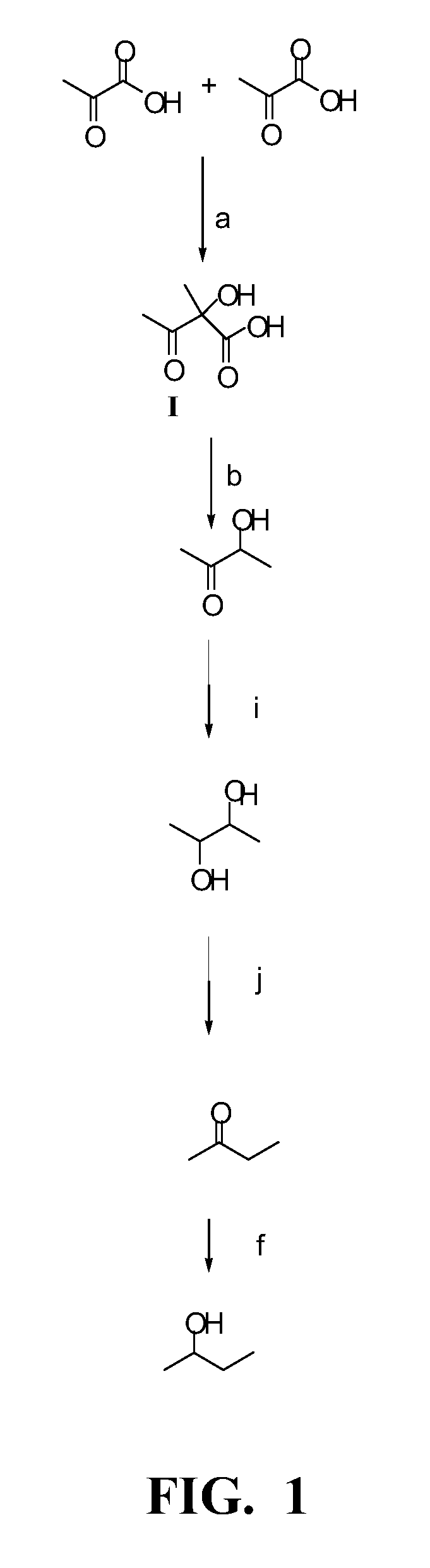

Enhanced pyruvate to 2,3-butanediol conversion in lactic acid bacteria

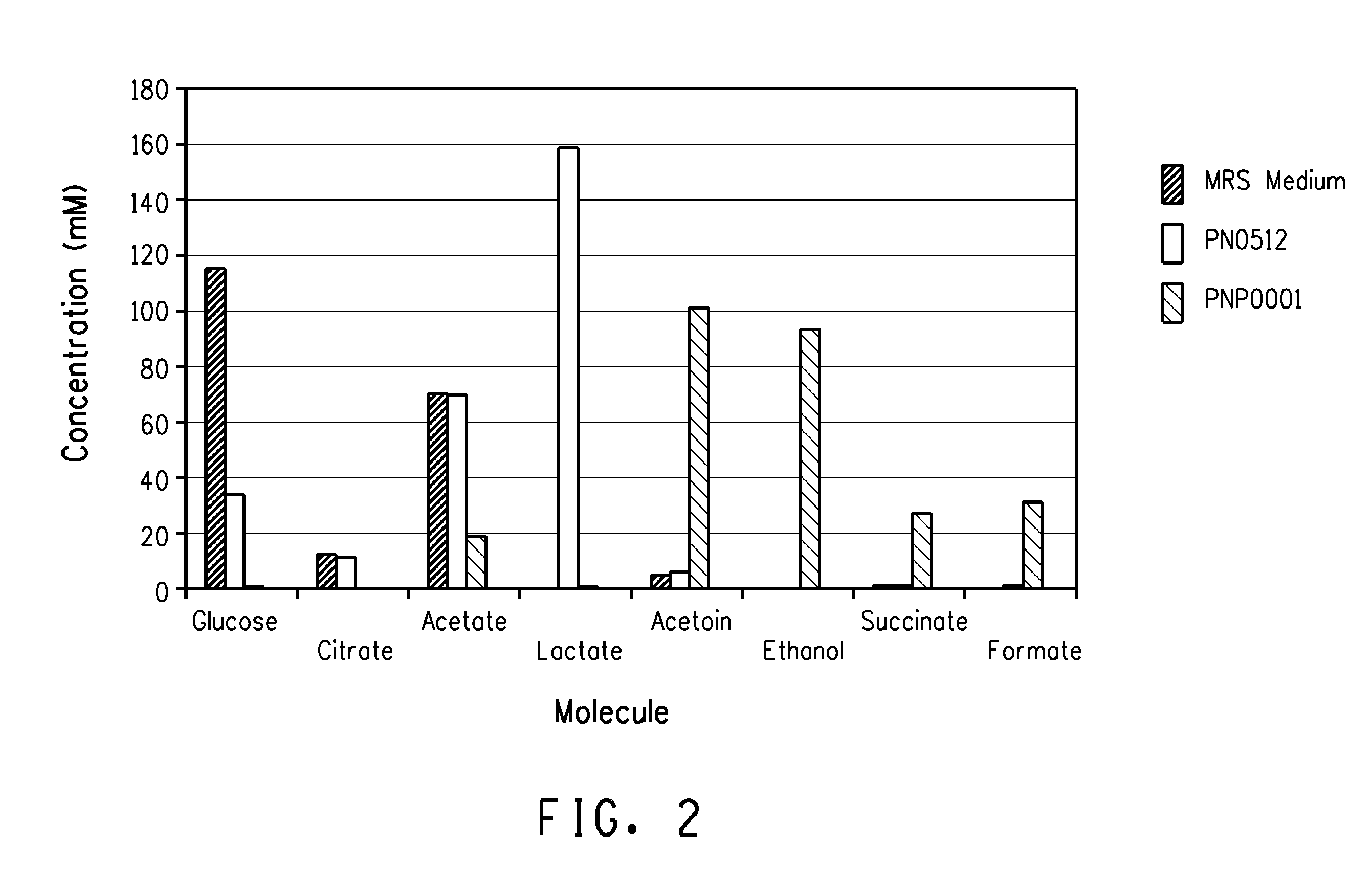

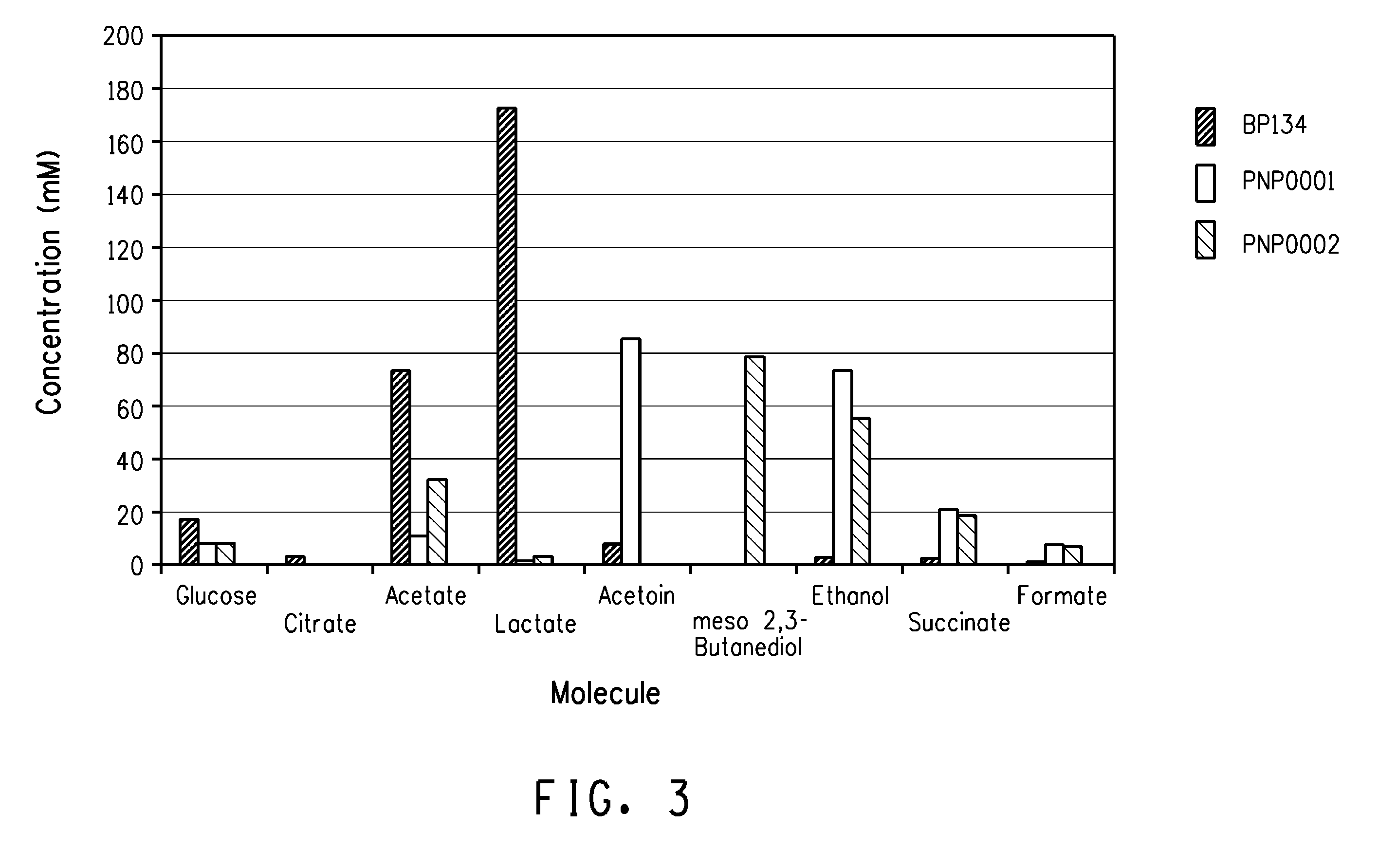

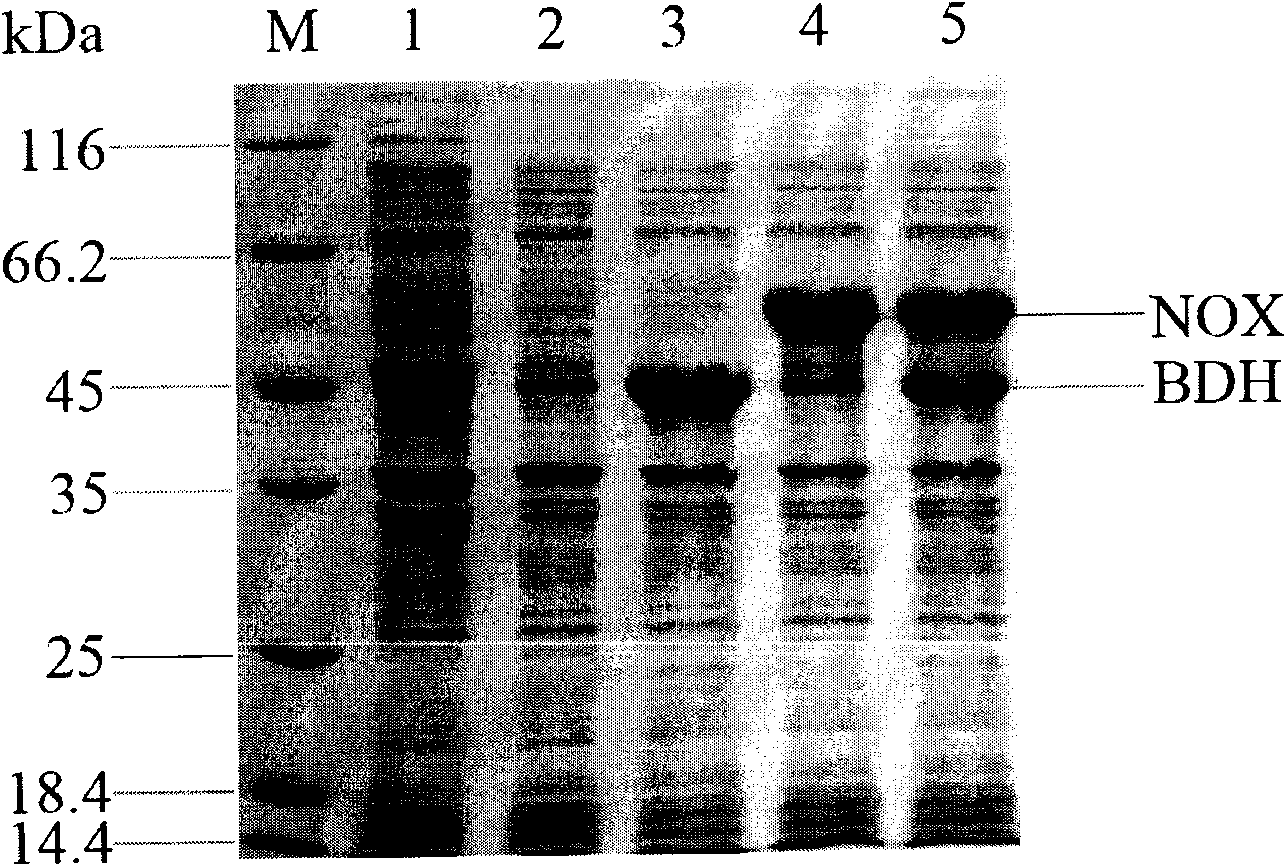

A high flux of metabolites from pyruvate to 2,3-butanediol in Lactobacillus plantarum was achieved through genetic engineering. Substantial elimination of lactate dehydrogenase activity in the presence of heterologously expressed butanediol dehydrogenase activity led to 2,3 butanediol production that was at least 49% of the total of major pyruvate-derived products.

Owner:GEVO INC

Enhanced pyruvate to 2,3-butanediol conversion in lactic acid bacteria

A high flux of metabolites from pyruvate to 2,3-butanediol in Lactobacillus plantarum was achieved through genetic engineering. Substantial elimination of lactate dehydrogenase activity in the presence of heterologously expressed butanediol dehydrogenase activity led to 2,3 butanediol production that was at least 49% of the total of major pyruvate-derived products.

Owner:GEVO INC

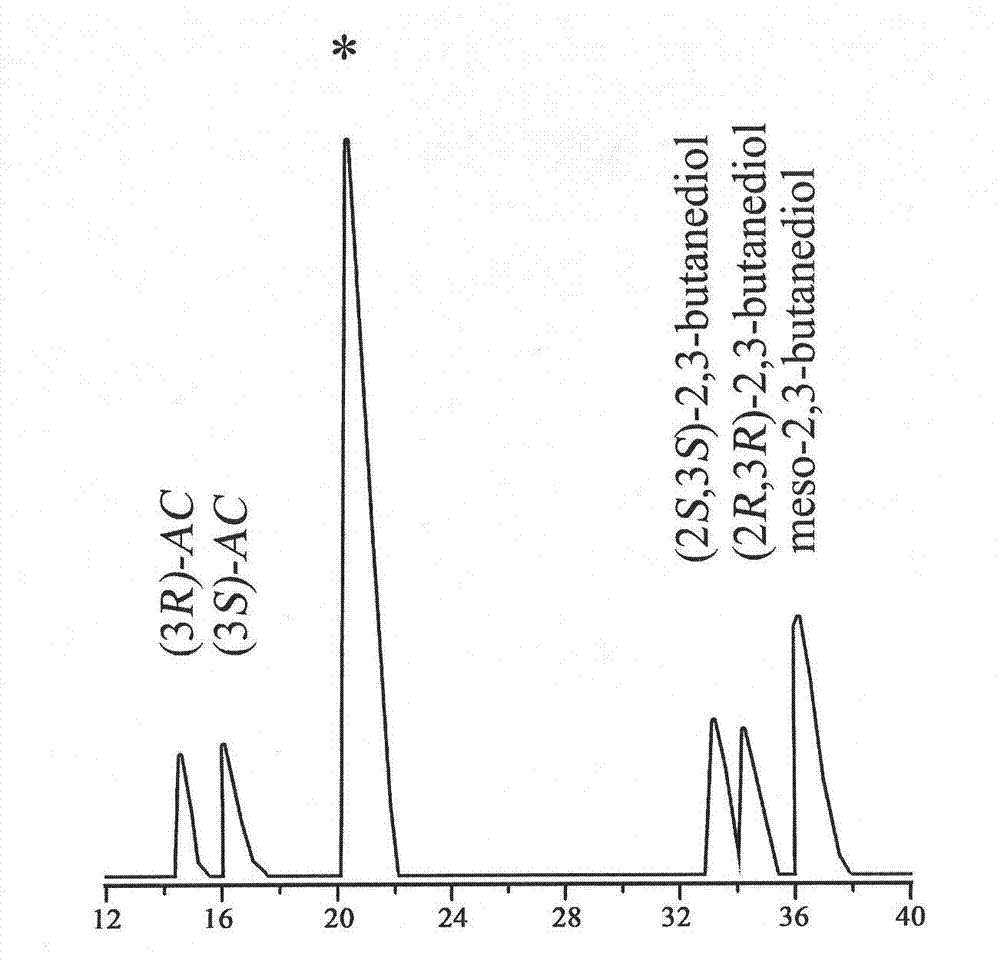

Gene recombination bacterium and application thereof in preparing chiral pure acetoin and 2,3-butanediol

InactiveCN101565685AEasy to operateAchieve productionBacteriaMicroorganism based processesEscherichia coliGram

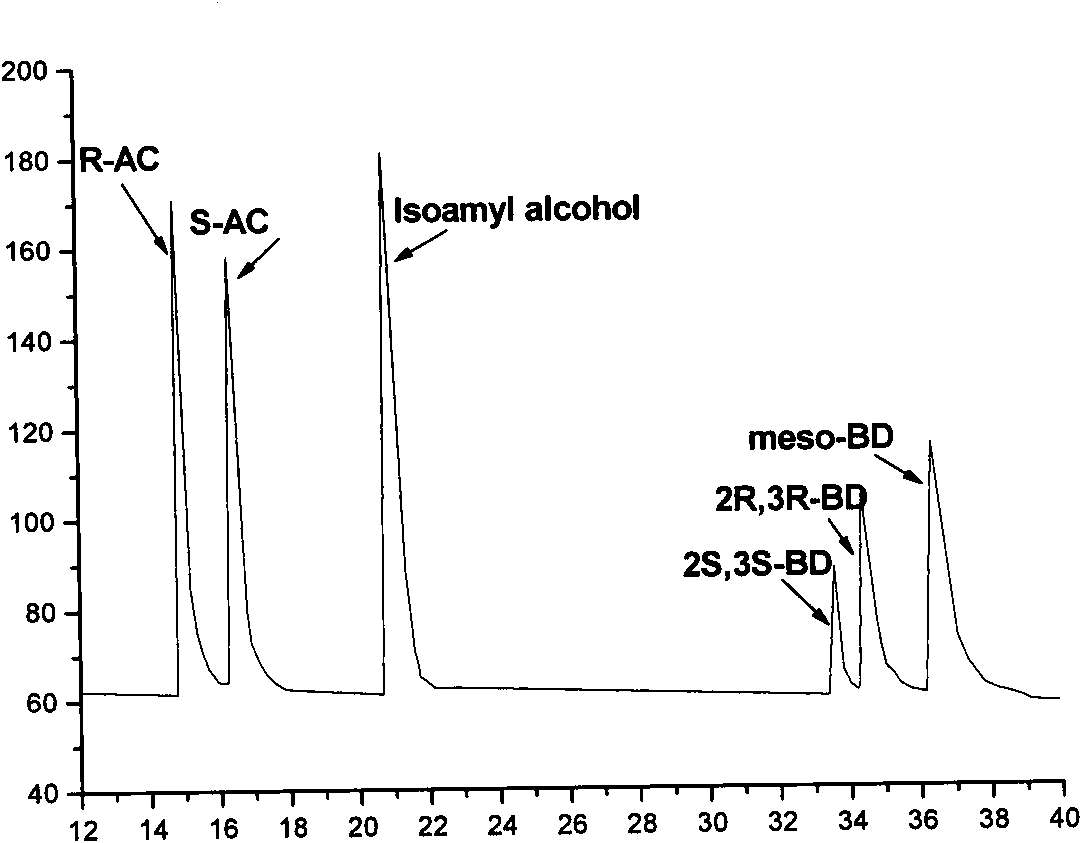

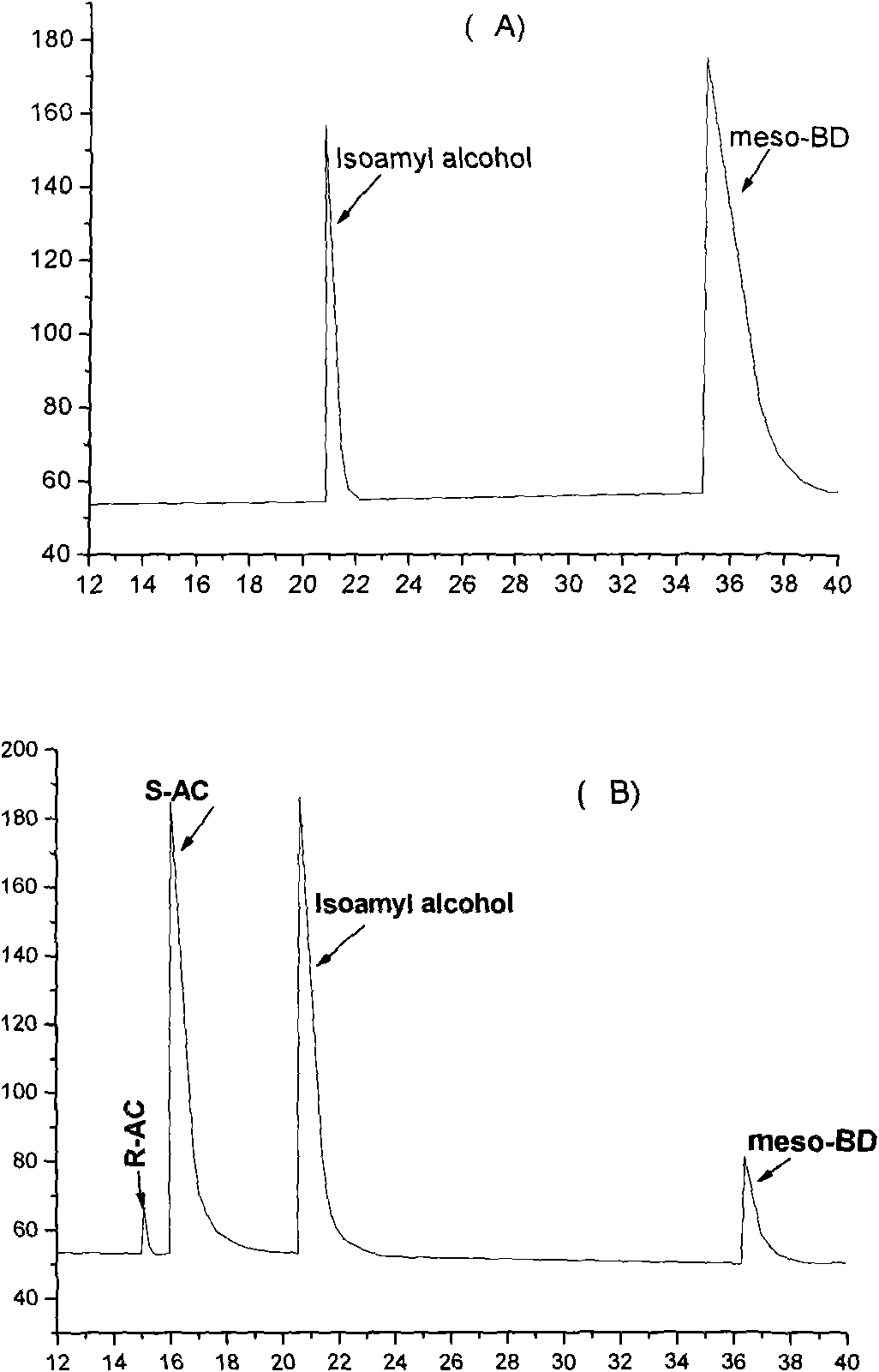

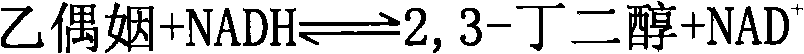

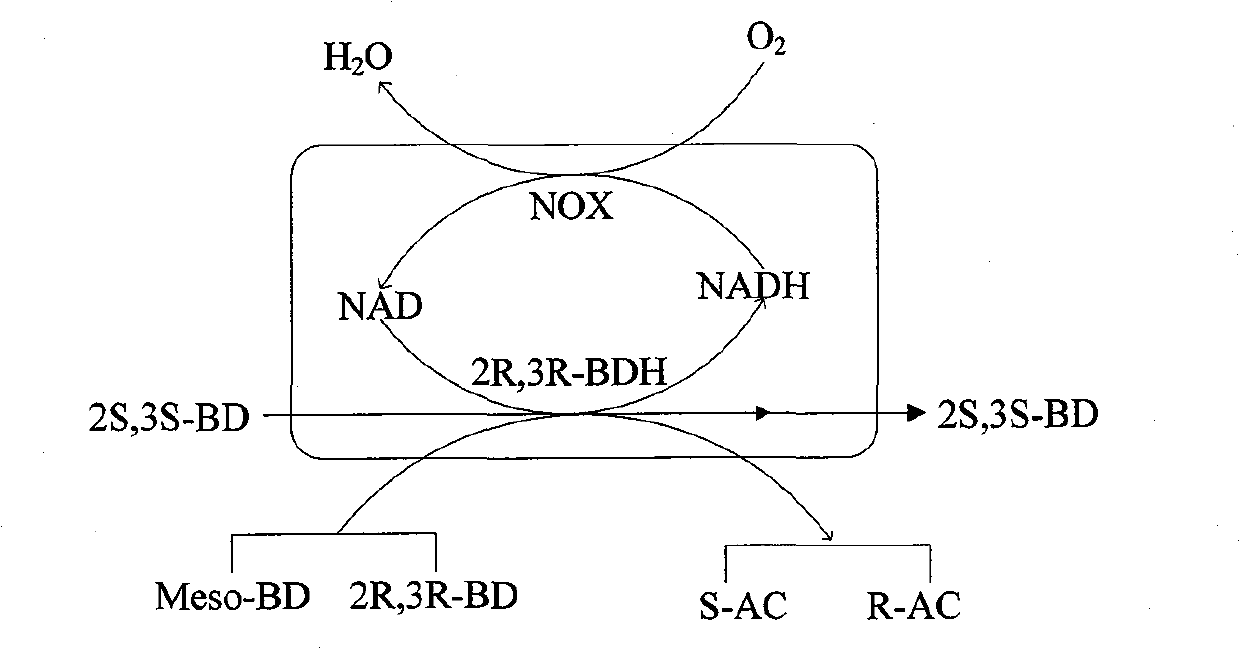

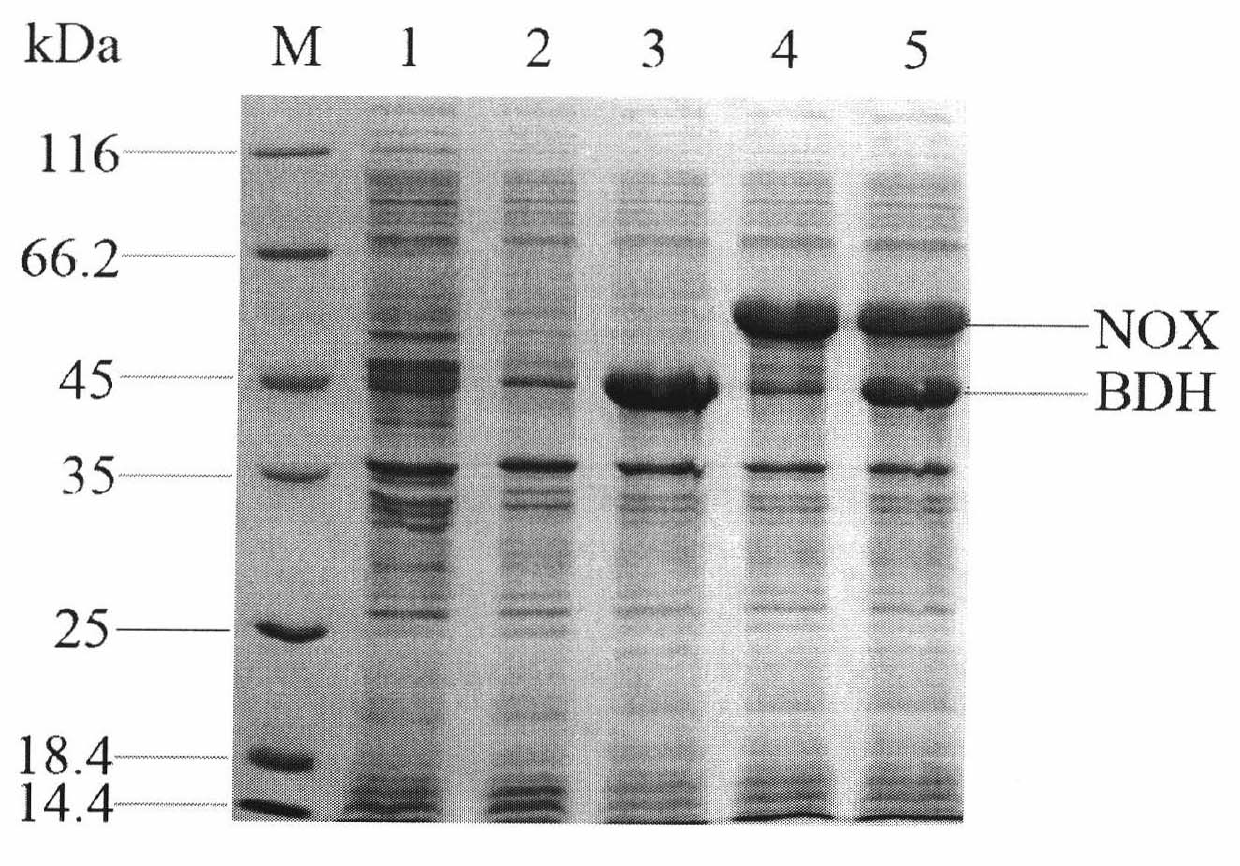

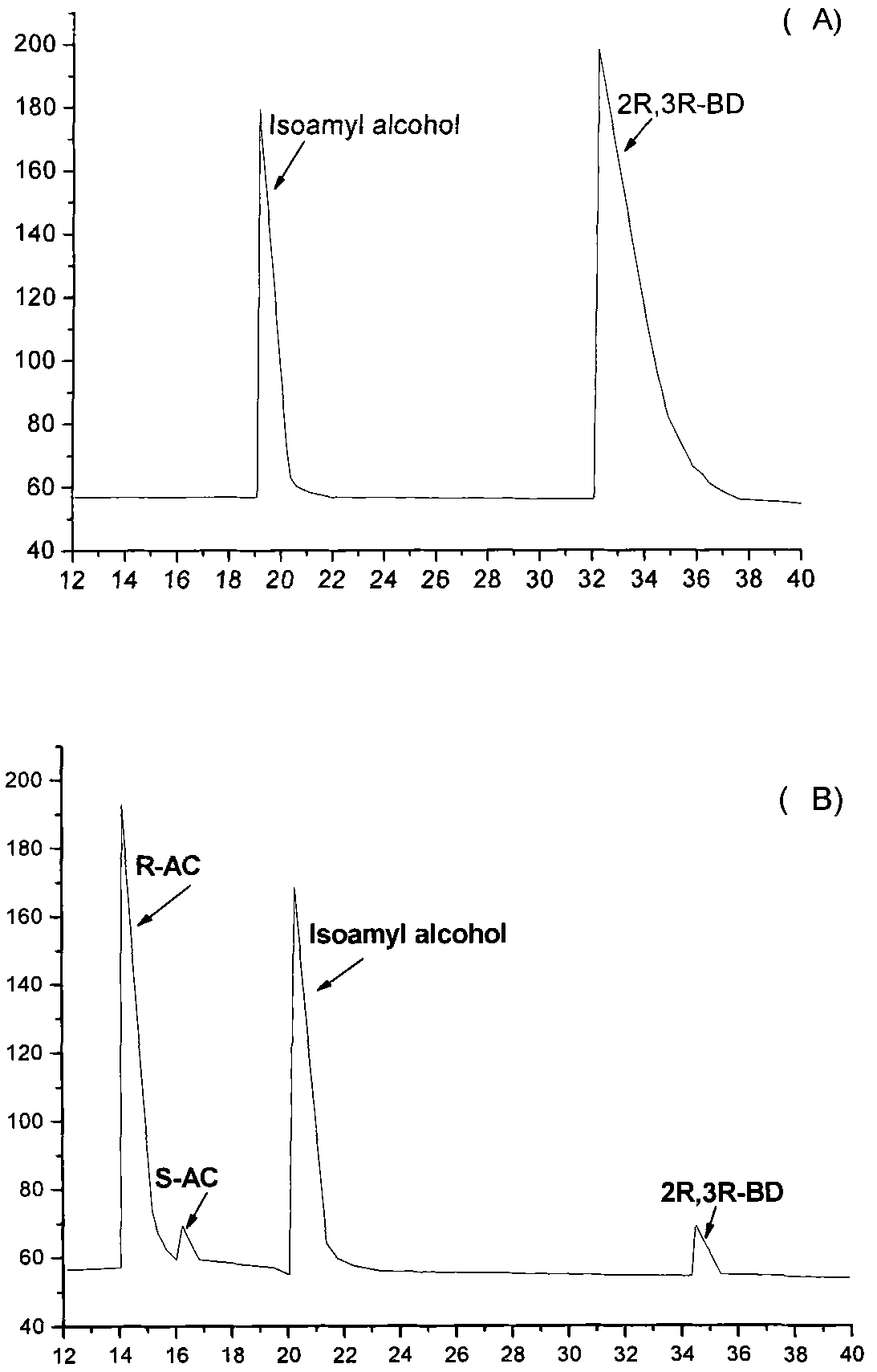

The invention discloses an E. coli BL21(pETDuet-ydjLnox) containing a 2R,3R-butanediol dehydrogenase gene ydjL and an NADH oxidase gene nox, wherein the strain is preserved in the 'China Center for Type Culture Collection' on December 23 in 2008, and the preservation number is CCTCC NO: M 208259. The invention also discloses application of a gene recombination bacterium in producing chiral S-AC by catalyzing meso-BD, producing chiral R-AC by catalyzing 2R,3R-BD and producing chiral pure 2S,3S-BD by splitting a 2,3-BD mixture. The concentration of a chiral AC prepared from the recombinant E. coli can reach over 6 grams per liter (the ee value is more than or equal to 96 percent); and the ee value of the chiral pure 2S,3S-BD is more than or equal to 98 percent, and the regeneration of a cofactor is achieved, thus the gene recombination bacterium has great industrial application prospect.

Owner:SHANDONG UNIV

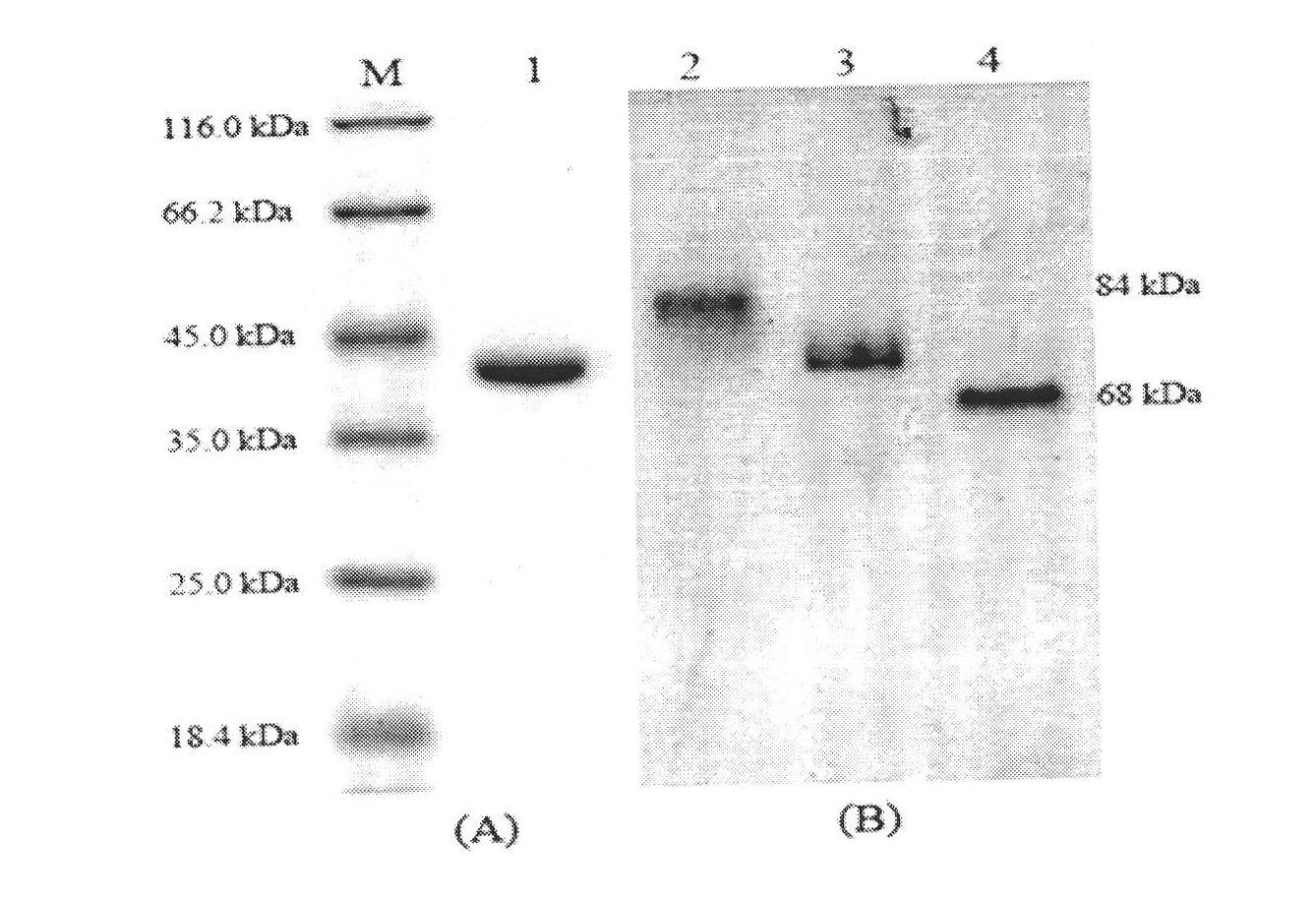

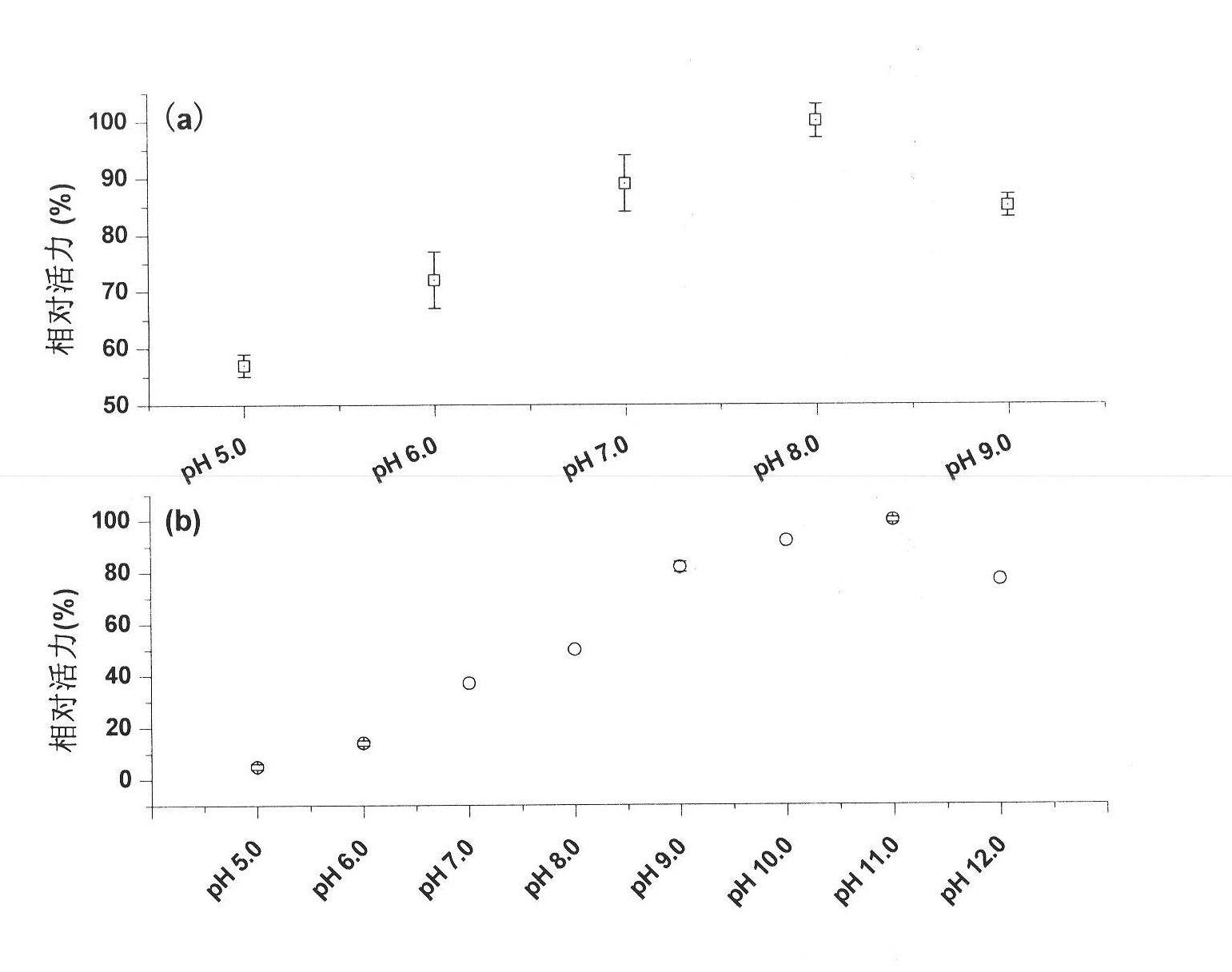

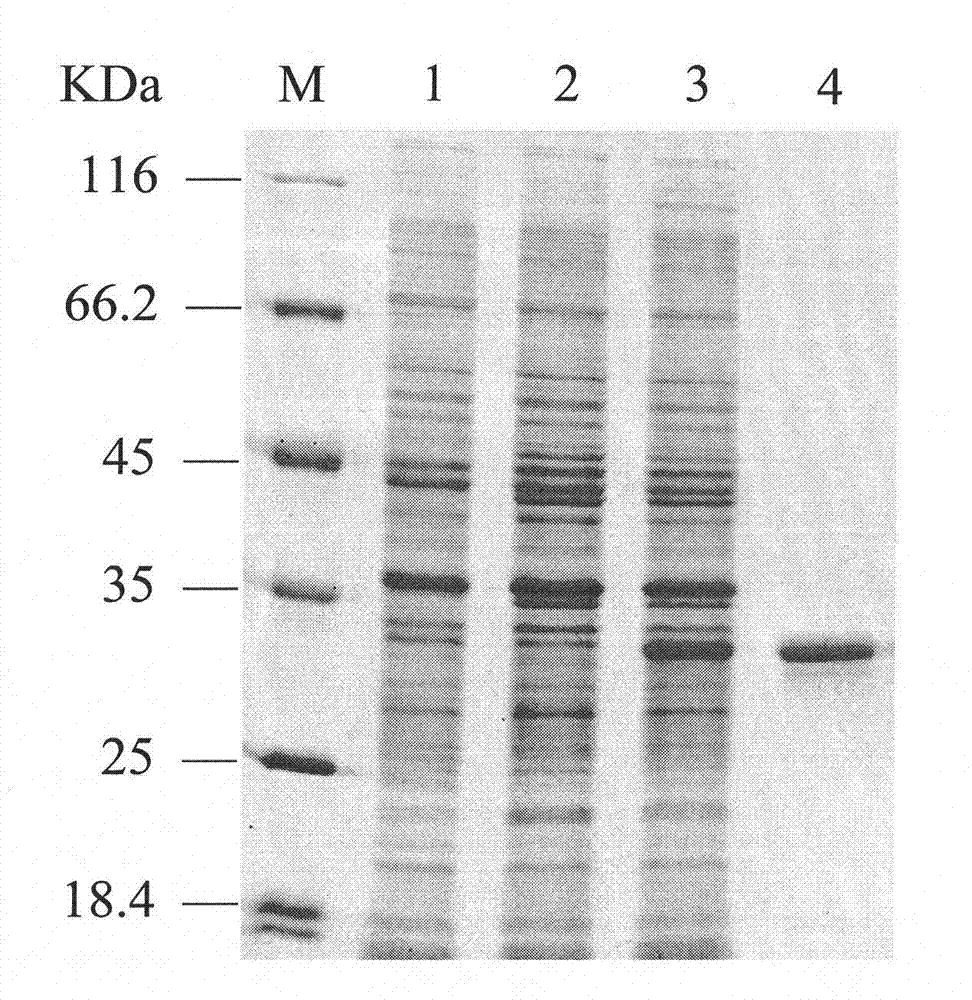

(2R, 3R)-2,3-butanediol dehydrogenase and coding gene and application thereof

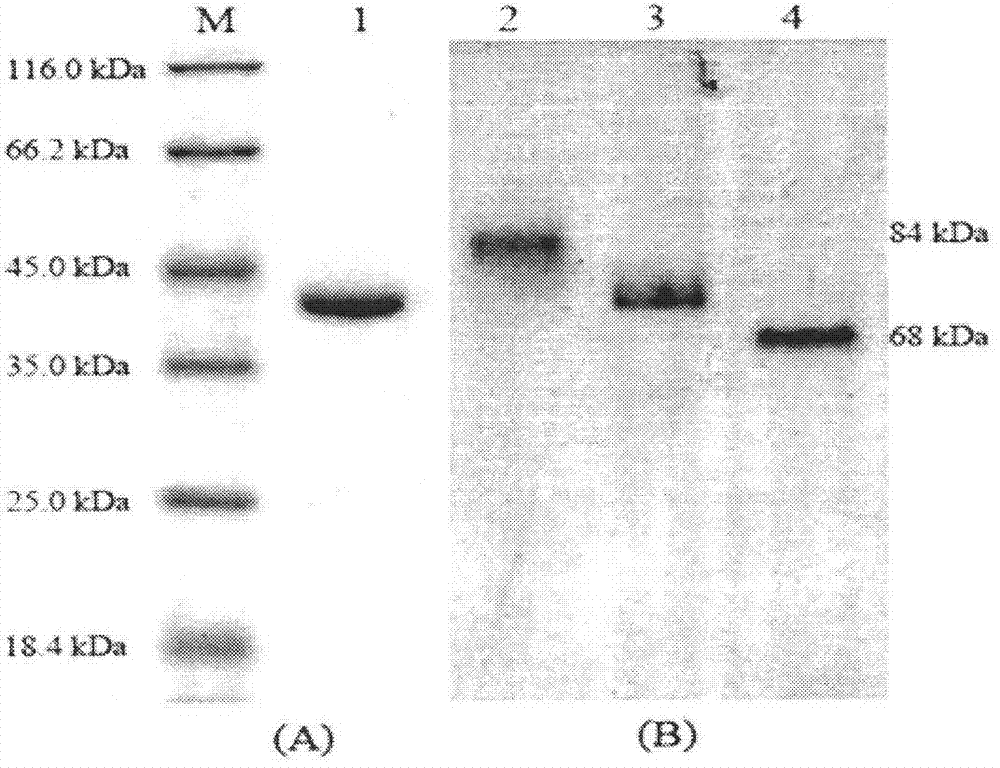

The invention discloses (2R, 3R)-2,3-butanediol dehydrogenase from paenibacillus polymyxa ATCC12321 and a coding gene and application thereof. Zymology verifies that the dehydrogenase has new characteristics: (2R, 3R)-2,3-butanediol is catalyzed to generate (R)-acetoin and meso-2,3-butanediol is catalyzed to generate (S)-acetoin by taking NAD+ as coenzyme, and the (R)-acetoin is catalyzed to generate (2R, 3R)-2,3-butanediol, the (S)-acetoin is catalyzed to generate meso-2,3-butanediol, and butanedione is catalyzed to generate (R)-acetoin by taking NADH as coenzyme. Moreover, the dehydrogenasesubstrate has high specificity and wide industrial application prospect.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

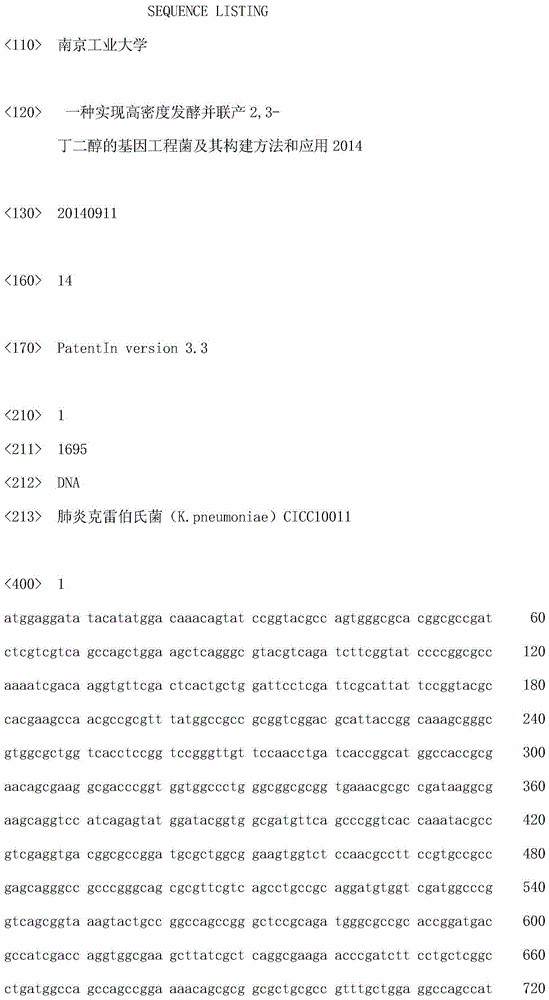

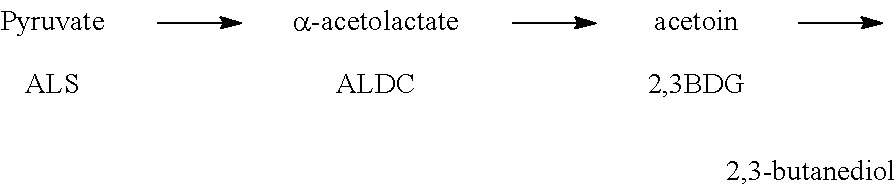

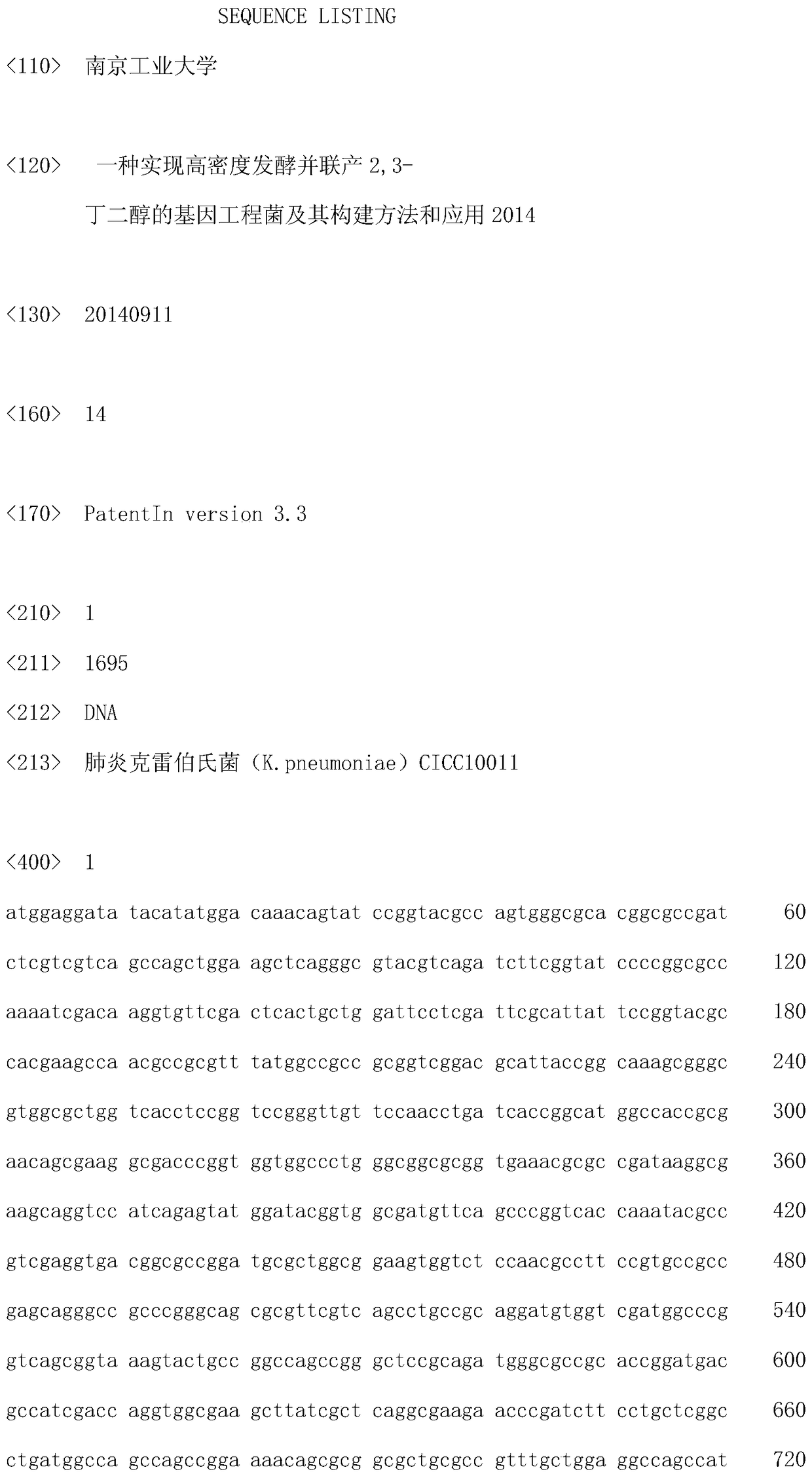

Genetically engineered bacteria realizing high-density fermentation co-production of 2,3-butanediol as well as construction method and application thereof

ActiveCN104560848AReduce culture volumeLess investmentBacteriaHydrolasesBiotechnologyEscherichia coli

The invention discloses genetically engineered bacteria realizing high-density fermentation co-production of 2,3-butanediol as well as a construction method and an application thereof. The genetically engineered bacteria are constructed by integrating three key enzyme genes such as alpha-acetolactate synthetase encoding genes, alpha-acetolacetate decearboxylase encoding genes and 2,3-butanediol dehydrogenase encoding genes onto Escherichia coli chromosomes in a 2,3-butanediol synthesis path. According to the strain fermentation process, the content of the byproduct acetic acid is reduced, so that high-density fermentation can be realized, and 2,3-butanediol with high additional value is co-produced. In addition, the invention also discloses a method for realizing high-density fermentation co-production of other compounds and 2,3-butanediol genetically engineered bacteria and an application thereof. The 2,3-butanediol can be produced by virtue of high-density fermentation, and polyhydroxyalkanoates or functional proteins also can be co-produced, so that low-cost and high-efficiency co-production of the polyhydroxyalkanoates or functional proteins and the 2,3-butanediol is realized, and the genetically engineered bacteria have important industrial application values.

Owner:NANJING UNIV OF TECH

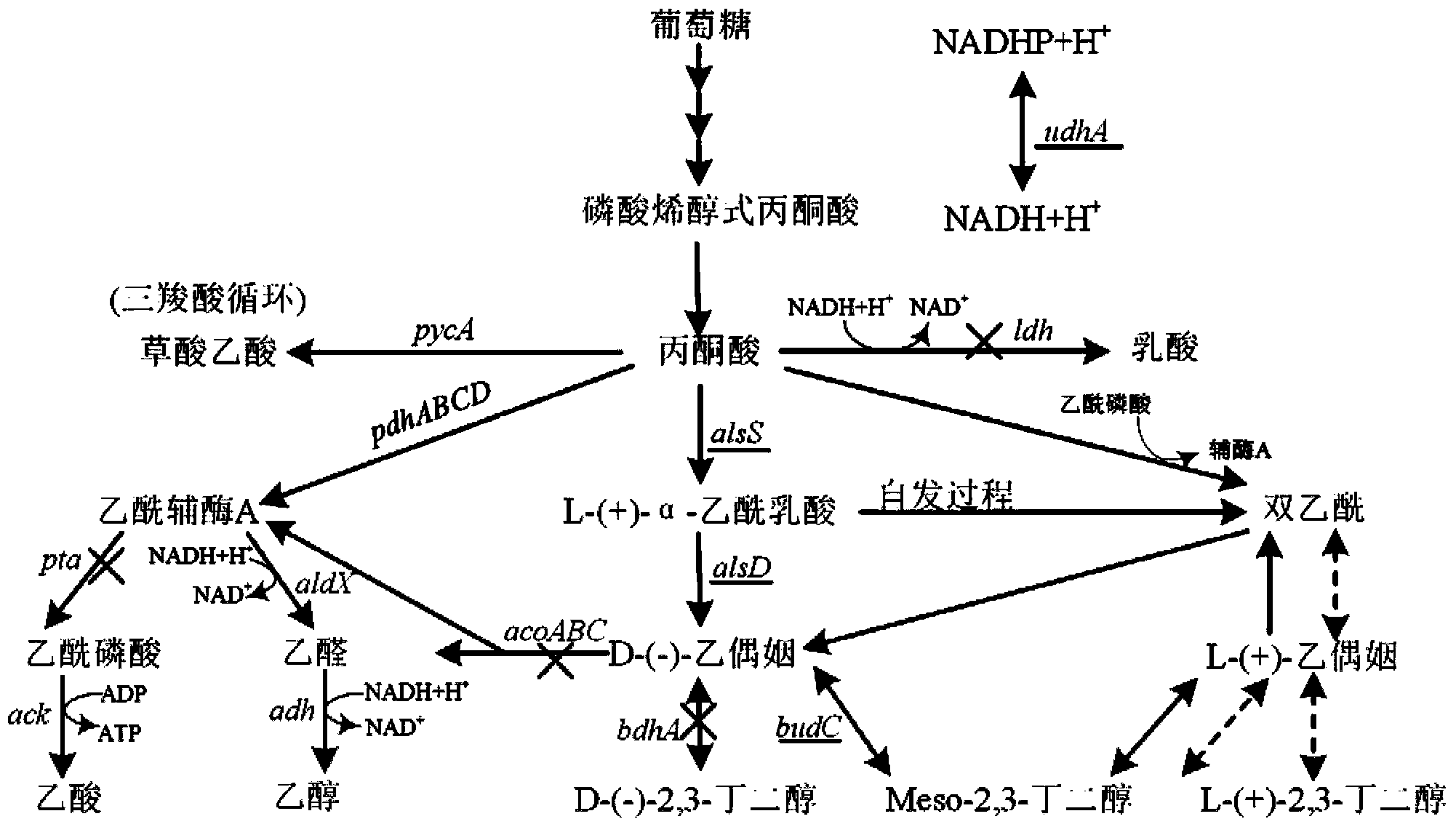

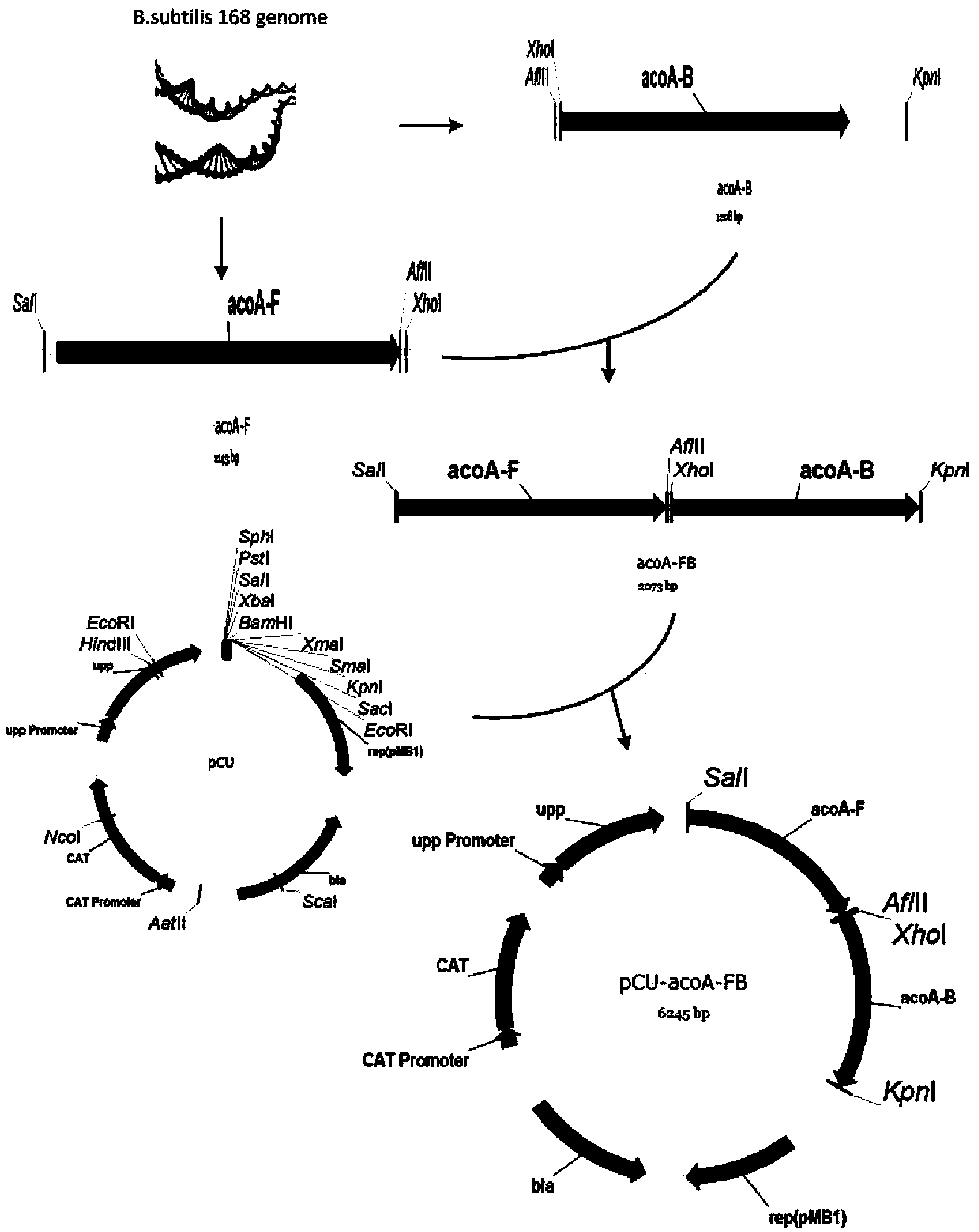

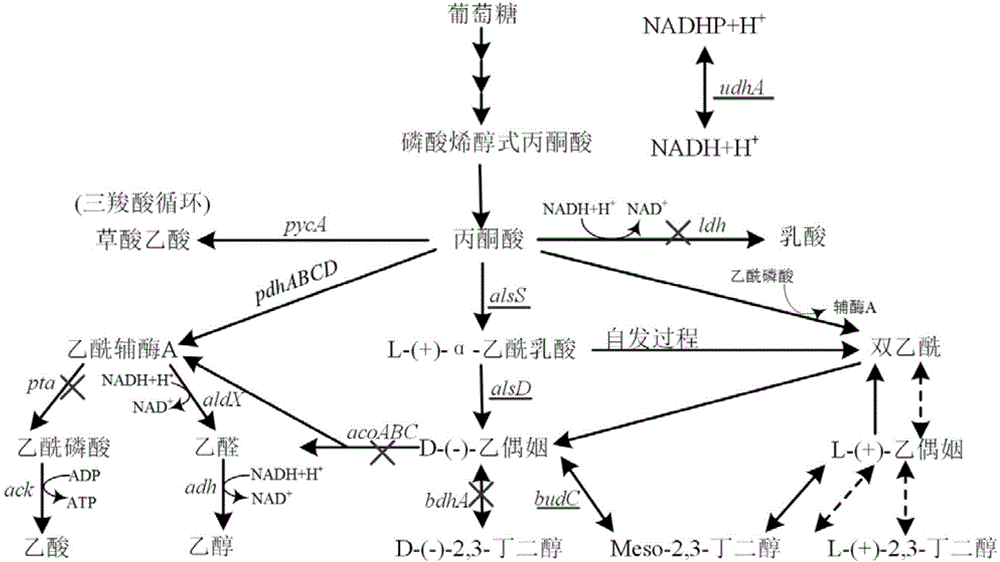

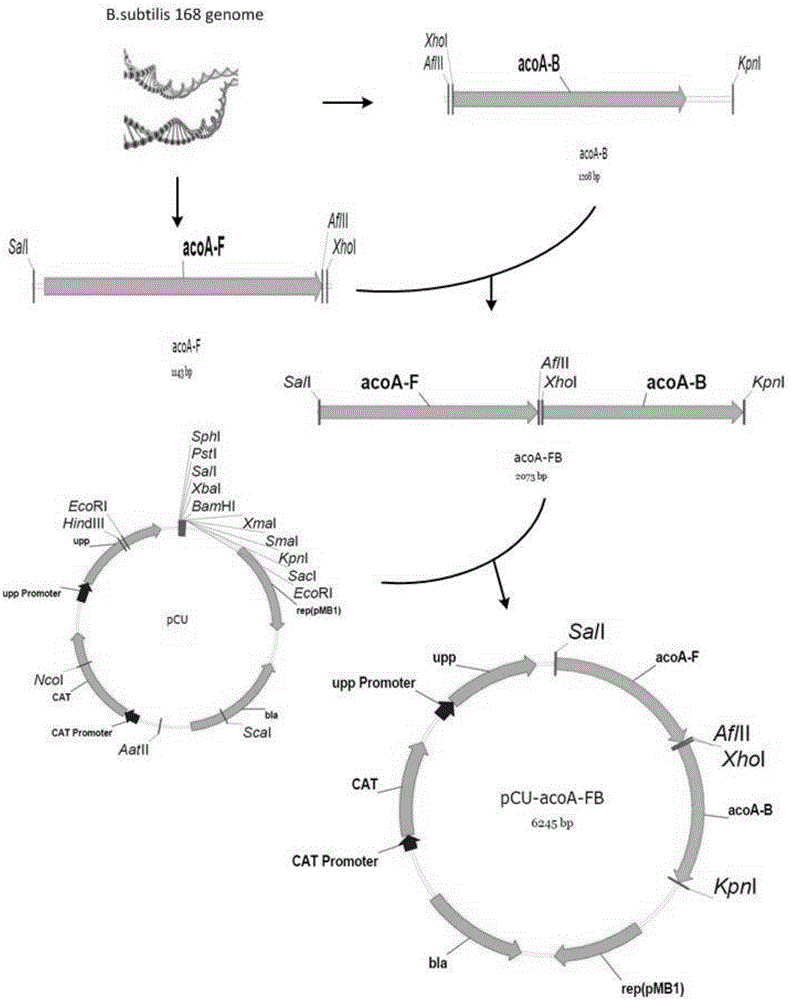

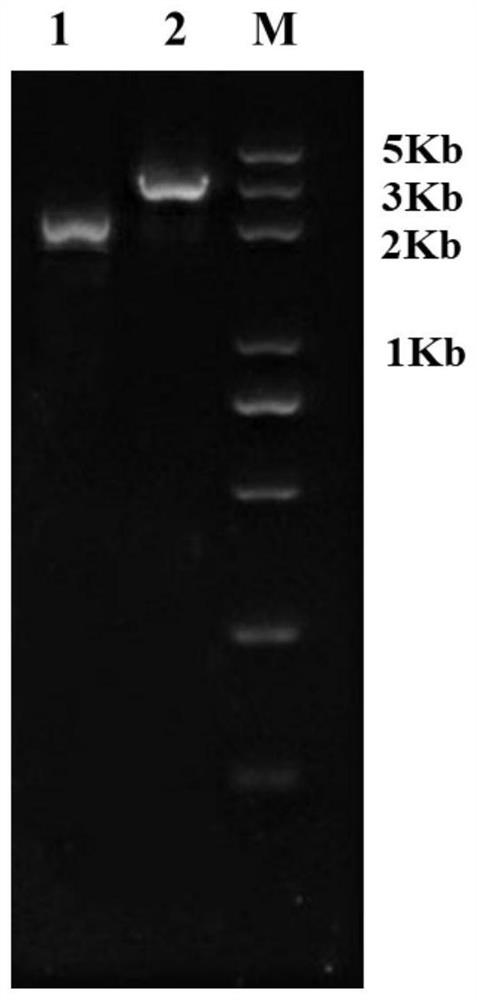

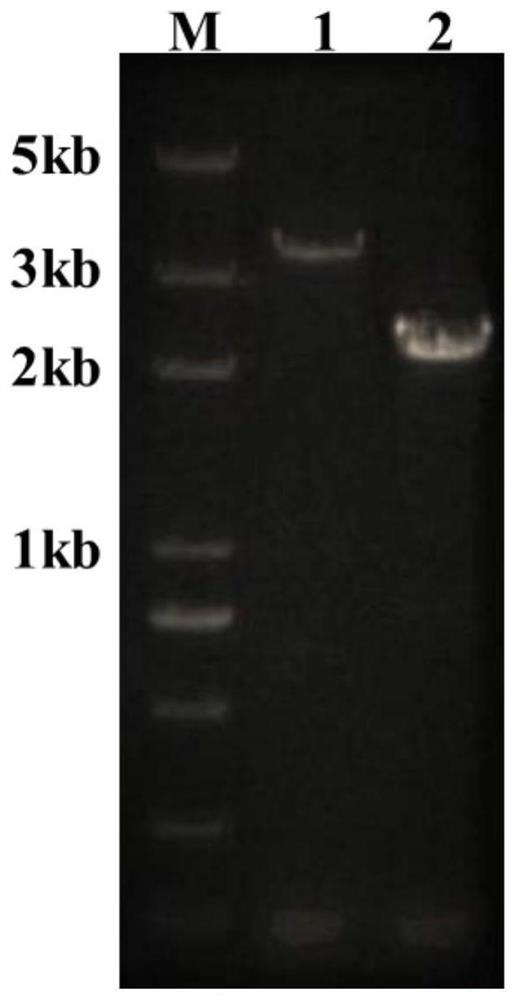

Bacillus subtilis strain for producing high-purity chiral meso-2,3-butanediol as well as construction method and application of strain

ActiveCN103451141AIncrease productionHigh yieldBacteriaMicroorganism based processesForce equilibriumAcetic acid

The invention discloses a bacillus subtilis strain for producing high-purity chiral meso-2,3-butanediol as well as a construction method and application of the strain. The construction method comprises the steps of knocking out an acoA gene of a direct substrate of 2,3-butanediol, acetoin in a degradation pathway, from bacillus subtilis, knocking out an acetoin reductase coding gene bdhA, knocking out a pta gene in a byproduct acetic acid formation path and knocking out a 1dh gene in a byproduct lactic acid formation path, over-expressing a synthesis branch a1sSD promoter through a P43 strong promoter, over-expressing meso-2,3-butanediol dehydrogenase coding gene budC through a P43 strong promoter, and over-expressing a transhydrogenase coding gene udhA in a reducing force equilibrium process through a P43 strong promoter. The constructed bacillus subtilis engineering strain is safe and harmless, and can produce meso-2,3-butanediol with chiral purity greater than 99% by taking glucose as a substrate.

Owner:TIANJIN UNIV

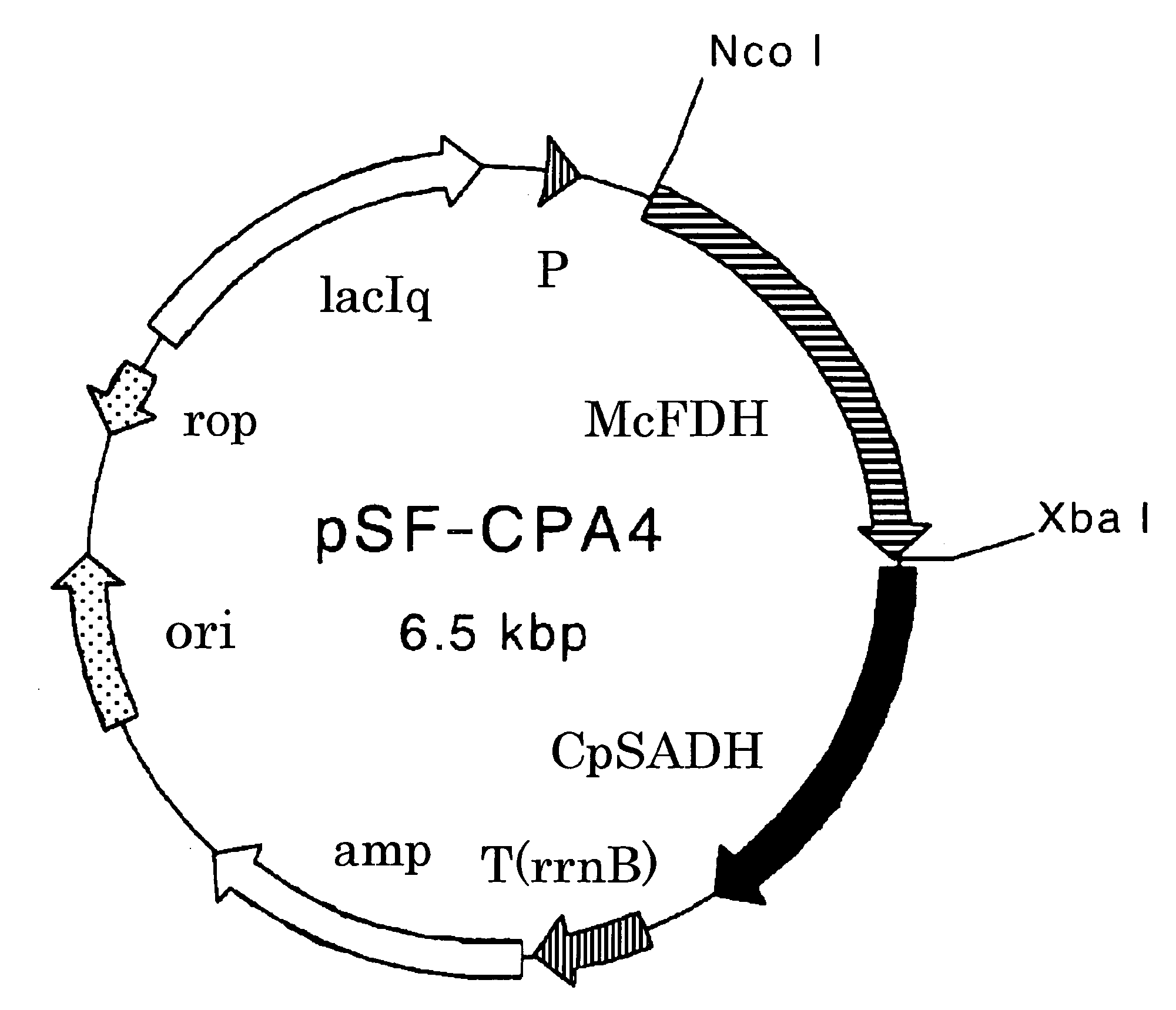

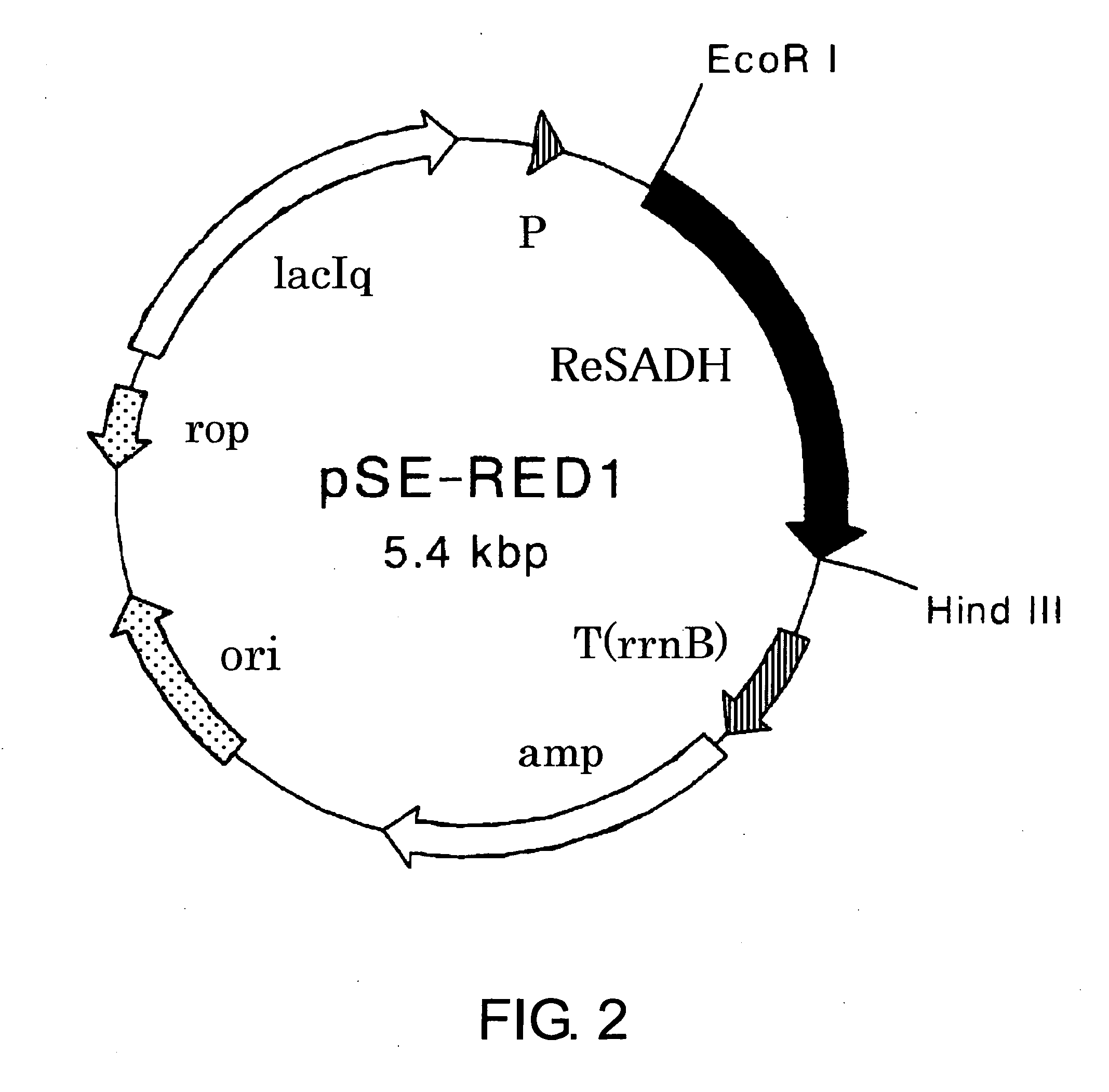

Process for Production of Optically Active Alcohol

The present invention provides methods for producing (S)-1,1,1-trifluoro-2-propanol, which include the step of reacting an enzyme of any one of alcohol dehydrogenase CpSADH, alcohol dehydrogenase ReSADH, carbonyl reductase ScoPAR, (2S,3S)-butanediol dehydrogenase ZraSBDH, carbonyl reductase ScGCY1, tropinone reductase HnTR1, tropinone reductase DsTR1, or alcohol dehydrogenase BstADHT, a microorganism or a transformant strain that functionally expresses the enzyme, or a processed material thereof, with 1,1,1-trifluoroacetone. The present invention also provides methods for producing (R)-1,1,1-trifluoro-2-propanol, which include the step of reacting alcohol dehydrogenase PfODH, a microorganism or a transformant strain that functionally expresses the enzyme, or a processed material thereof, with 1,1,1-trifluoroacetone.

Owner:DAICEL CHEM IND LTD

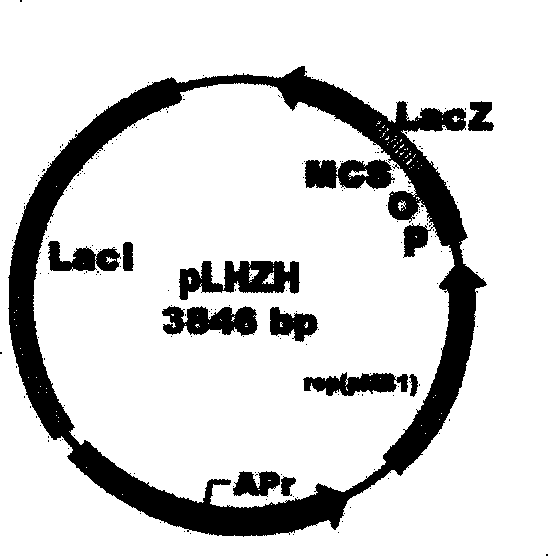

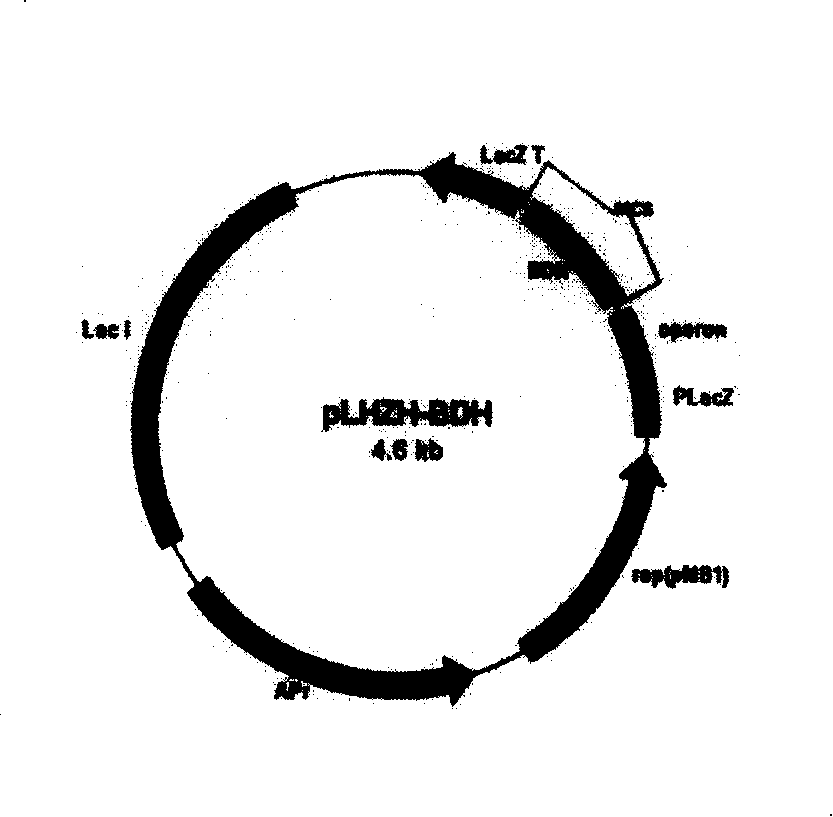

Lactose induction type expression vector and viscidity Serratieae converted therefrom

InactiveCN101235383AGreat practical valueGenetic Trait LimitsBacteriaMicroorganism based processesAgricultural scienceHigh level expression

The invention discloses a lactose induction type expression vector, which can utilize cheap lactose to replace expensive isopropyl thioamide-beta-D- galactoside (IPTG) to be exutory. The lactose induction type expression vector can be widely used on the expression of exogenous gene and the reconstruction of serratia marcescens metabolic pathway, for example, the lactose induction type expression vector is used to lead meso-2,3-butanediol dehydrogenase (meso-2,3-BDH) in serratia marcescens. The invention also discloses a serratia marcescens which utilizes gene recombination technique to reconstruct, which changes the metabolic pathway of natural meso-2,3-butanediol in bacteria through leading in exogenesis meso-2,3-butanediol dehydrogenase (meso-2,3-BDH) gene. The serratia marcescens which is reconstructed by gene recombination technique which is provided by the invention expresses meso-2,3-butanediol dehydrogenase in an expected level, which improves production and accumulation of meso-2,3-butanediol in host strain, and improves the productivity of meso-2,3-butanediol in serratia marcescens.

Owner:EAST CHINA UNIV OF SCI & TECH

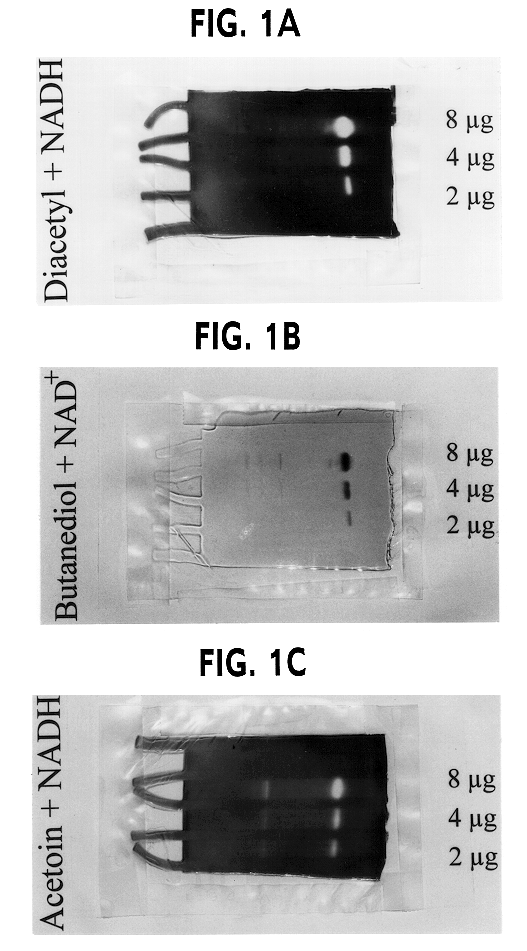

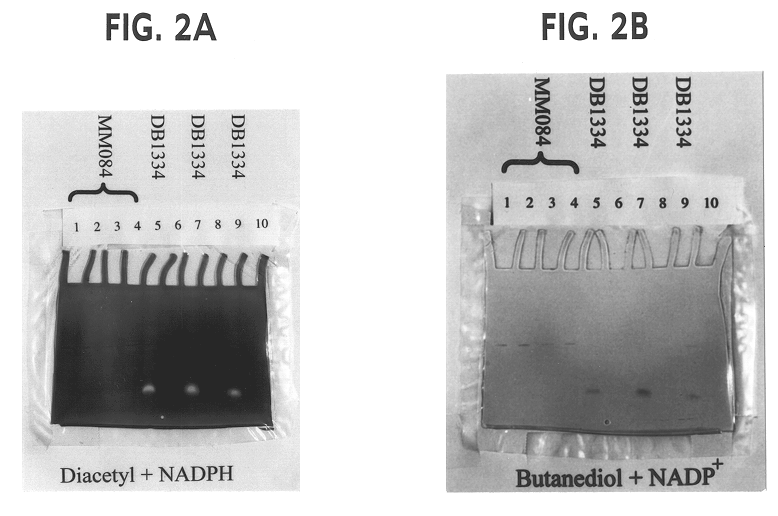

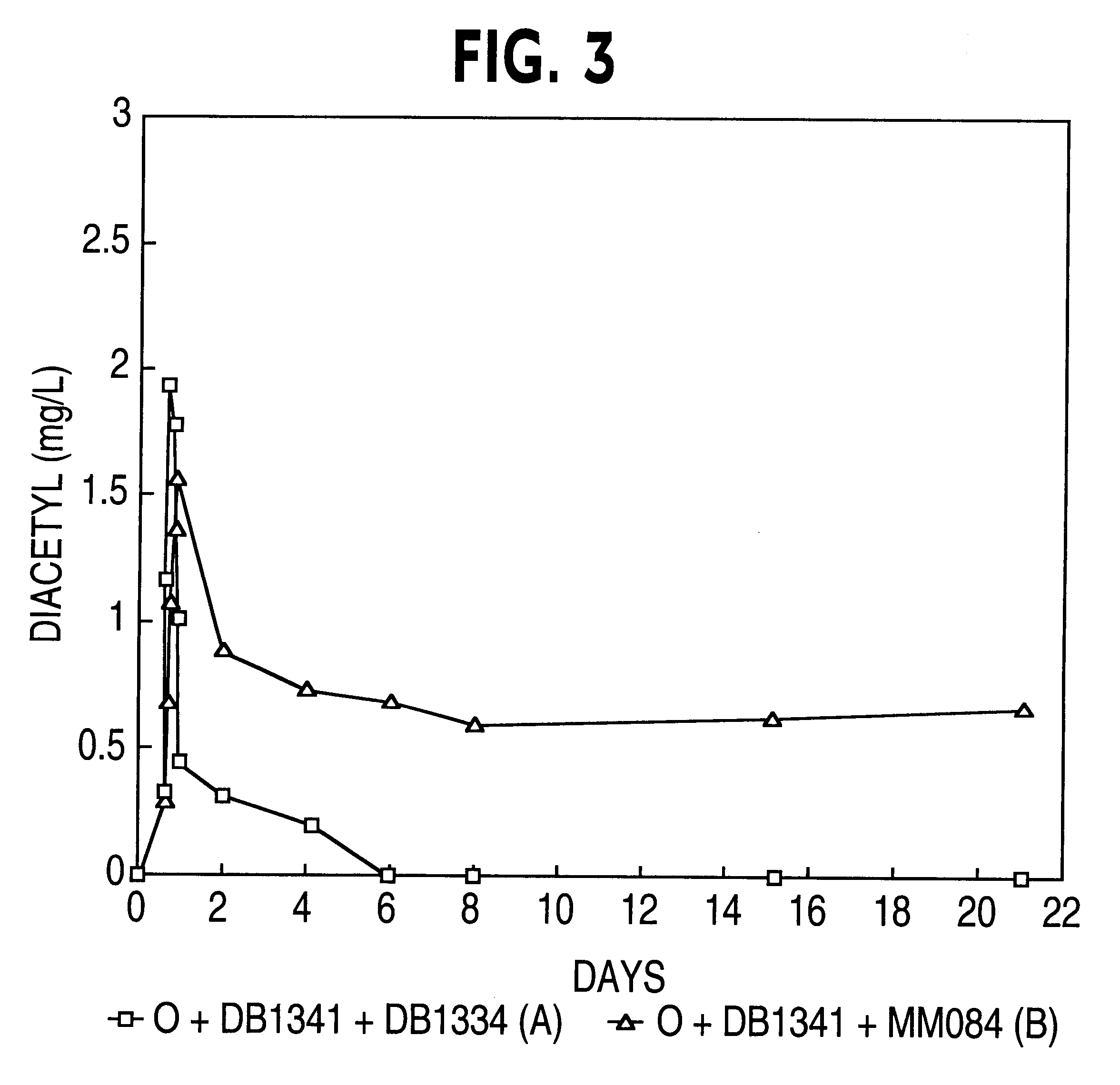

Genetically modified lactic acid bacteria having modified diacetyl reductase activities

InactiveUS6413765B1High activityReduce and remove diacetylBacteriaUnicellular algaeBacteroidesFruit juice

Genetically modified lactic acid bacteria having a reduced or lacking or enhanced diacetyl reductase activity, acetoin reductase activity and / or butanediol dehydrogenase activity are provided. Such bacteria are used in starter cultures in the production of food products including dairy products where it is desired to have a high content of diacetyl and for reducing or completely removing diacetyl in beverages including beers, fruit juices and certain types of wine, where the presence of diacetyl is undesired.

Owner:CHR HANSEN AS

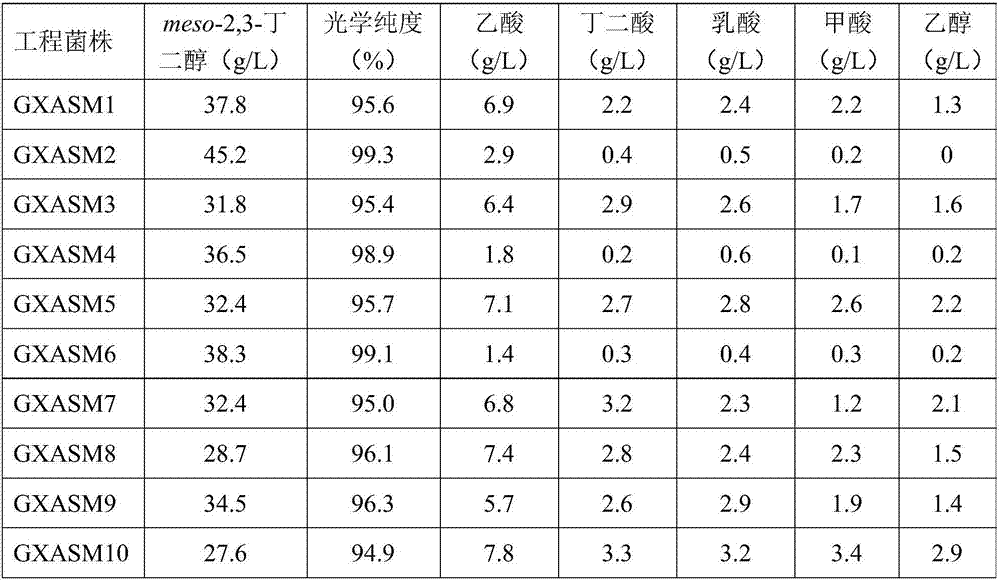

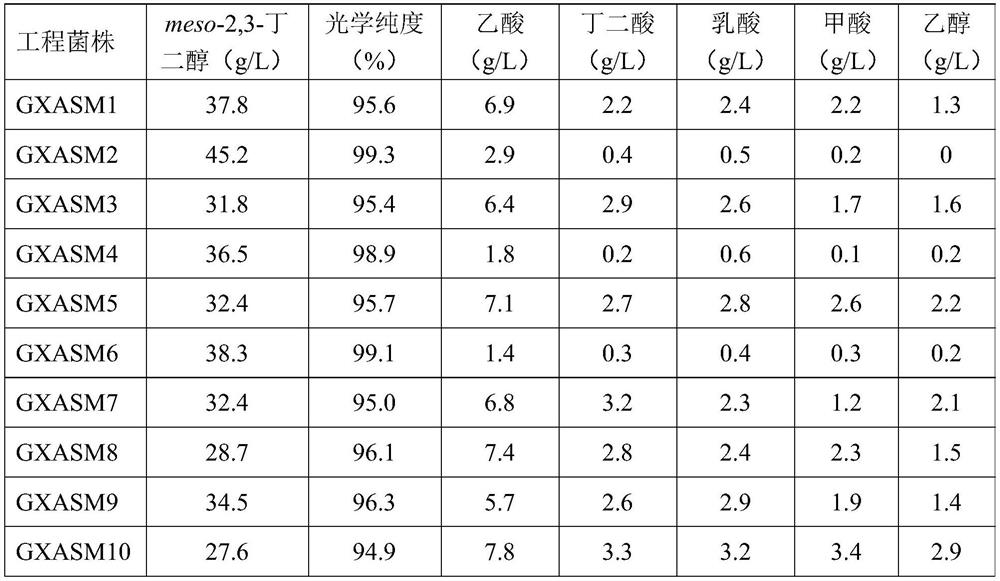

Construction method and application of high-yield engineering strain for optically pure meso-2,3-butanediol

The invention discloses construction of a high-yield engineering strain for optically pure meso-2,3-butanediol. A construction method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and a meso-2,3-butanediol dehydrogenase gene, afterwards, splicing to obtain a gene cluster containing the three genes, then introducing the gene cluster into an expression vector to obtain a polycistronic recombinant plasmid, and finally introducing the recombinant plasmid into a host bacterium E. coli again, so that a high-yield engineering bacterium is obtained. Synthesis raw materials used by the bacterium are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield, high in production efficiency and good in stability, has the highest yield which can reach 91.5g / L and the optical purity which can reach 99 percent or above. The invention discloses application of the high-yield engineering strain to the production of the optically pure meso-2,3-butanediol by utilizing cheap cassava meal as a carbon source and utilizing cottonseed protein powder, soybean pulp powder, soybean cake powder or peanut protein powder as a nitrogen source at the same time. The production cost is lowered.

Owner:GUANGXI ACAD OF SCI

Coding gene of meso-2,3-butanediol dehydrogenase, recombinase and preparation method and application of recombinase

InactiveCN105200068AGood catalyticWide substrate applicabilityBacteriaMicroorganism based processesBacillus licheniformisDiol

The invention discloses a coding gene of meso-2,3-butanediol dehydrogenase, a recombinant expression vector and recombinant expression transformant with the gene, a preparation method of recombinase, and application of the recombinase as a catalyst in an asymmetrically reducing prochiral dicarbonyl compound for preparing optical activity chiral diols. The meso-2,3-butanediol dehydrogenase comes from Bacillus licheniformis CICIMB0109, can be used as a catalyst for efficiently synthesizing chiral diols, is high in catalytic activity and stereoselectivity, mild in suitable reaction condition and friendly to the environment, and has quite good application and development prospects.

Owner:JIANGNAN UNIV

Process for production of alcohols by microbial fermentation

The invention provides method for producing butanediol and specifically 2,3-butanediol by anaerobic fermentation of a gaseous substrate comprising CO by a culture of at least one micro-organism. In accordance with particular methods of the invention, 2,3-butanediol is produced by anaerobic fermentation of substrates including carbohydrates and carbon monoxide. The invention further provides for the up-regulation of a native 2,3-butanediol dehydrogenase gene in the at least one micro-organism. The 2,3-butanediol can be further converted to compounds such as butene(s), butadiene and methyl ethyl ketone. These compounds can be further converted to chemical products such as 2-butanol.

Owner:LANZATECH NZ INC

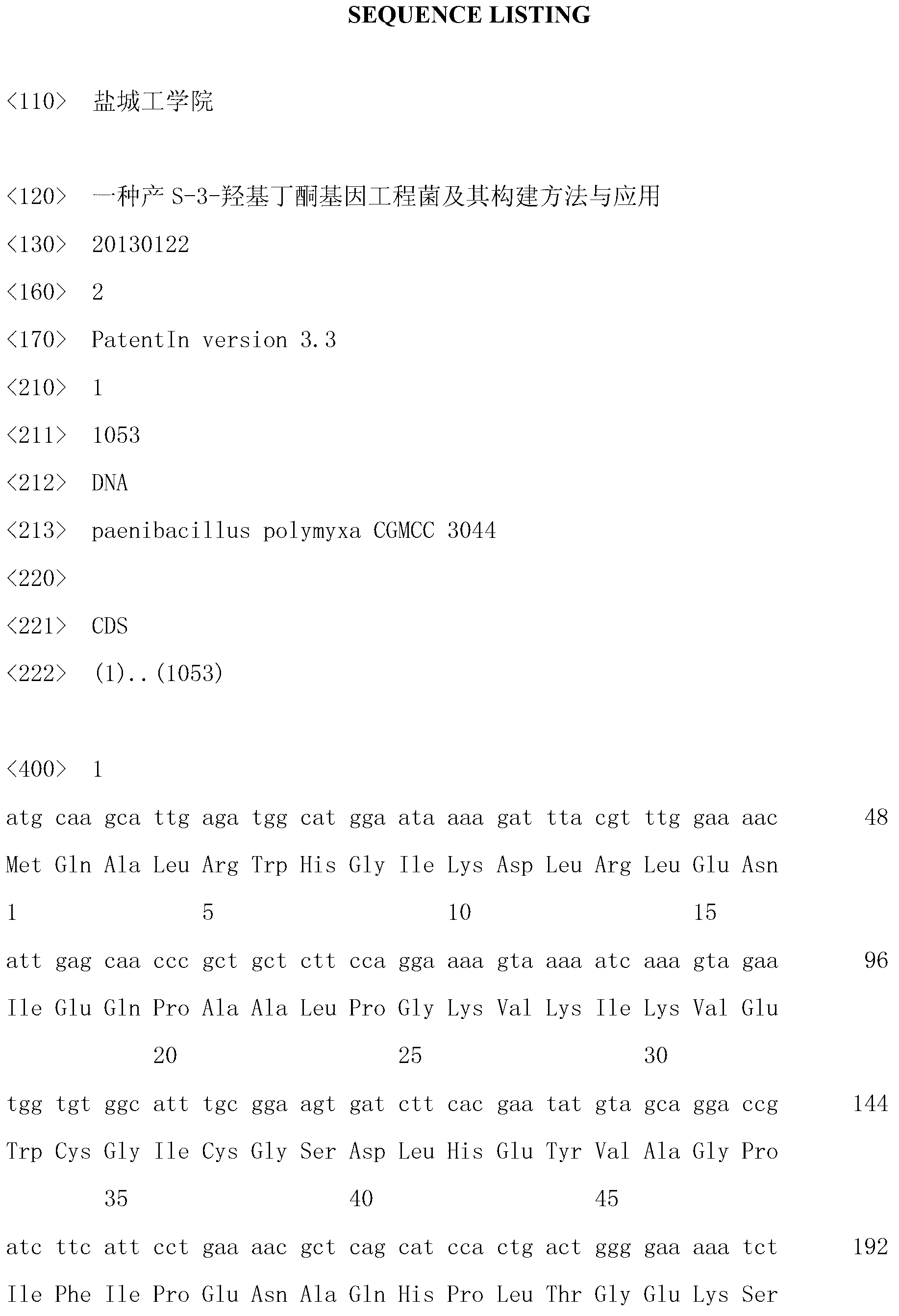

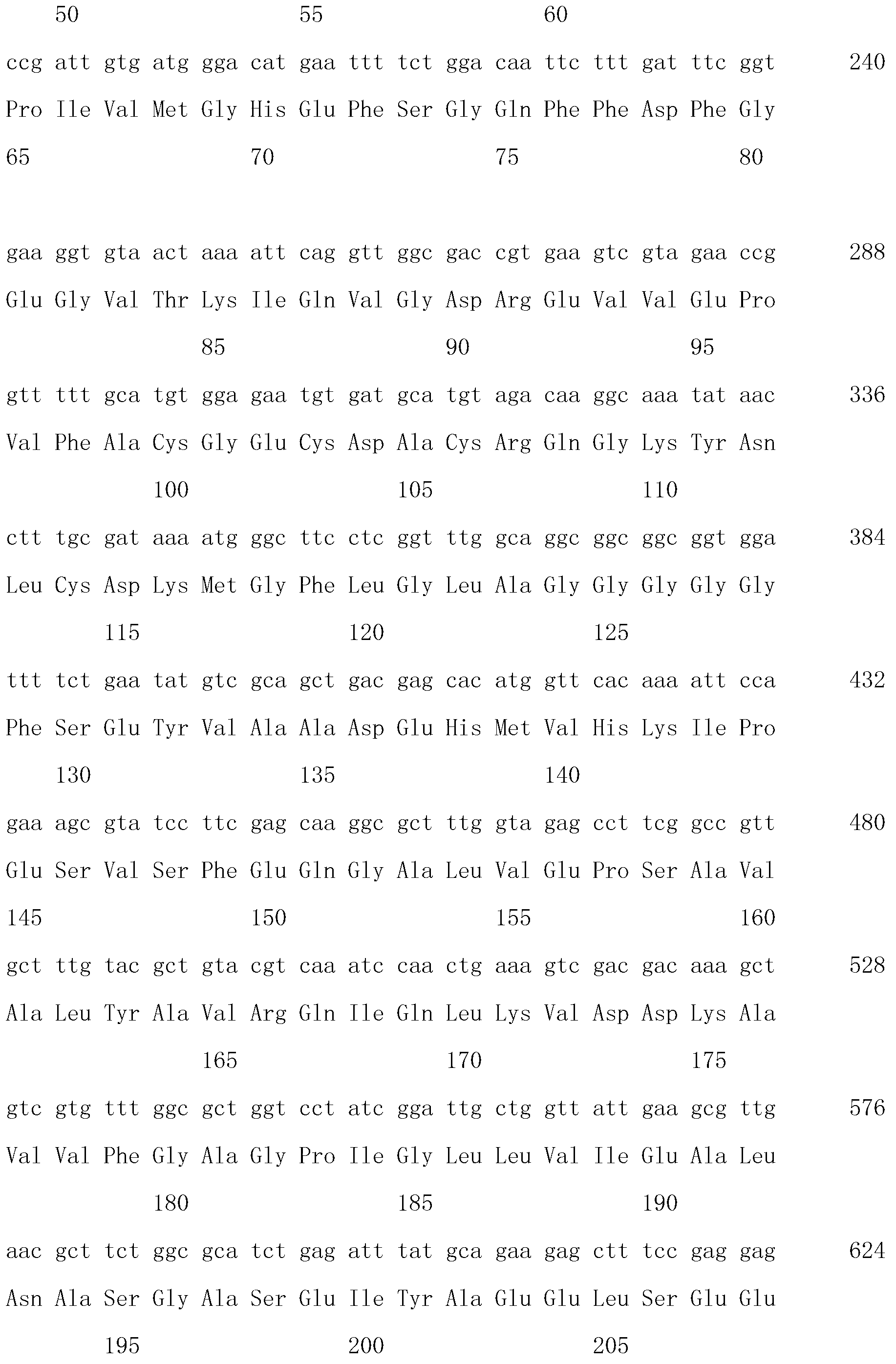

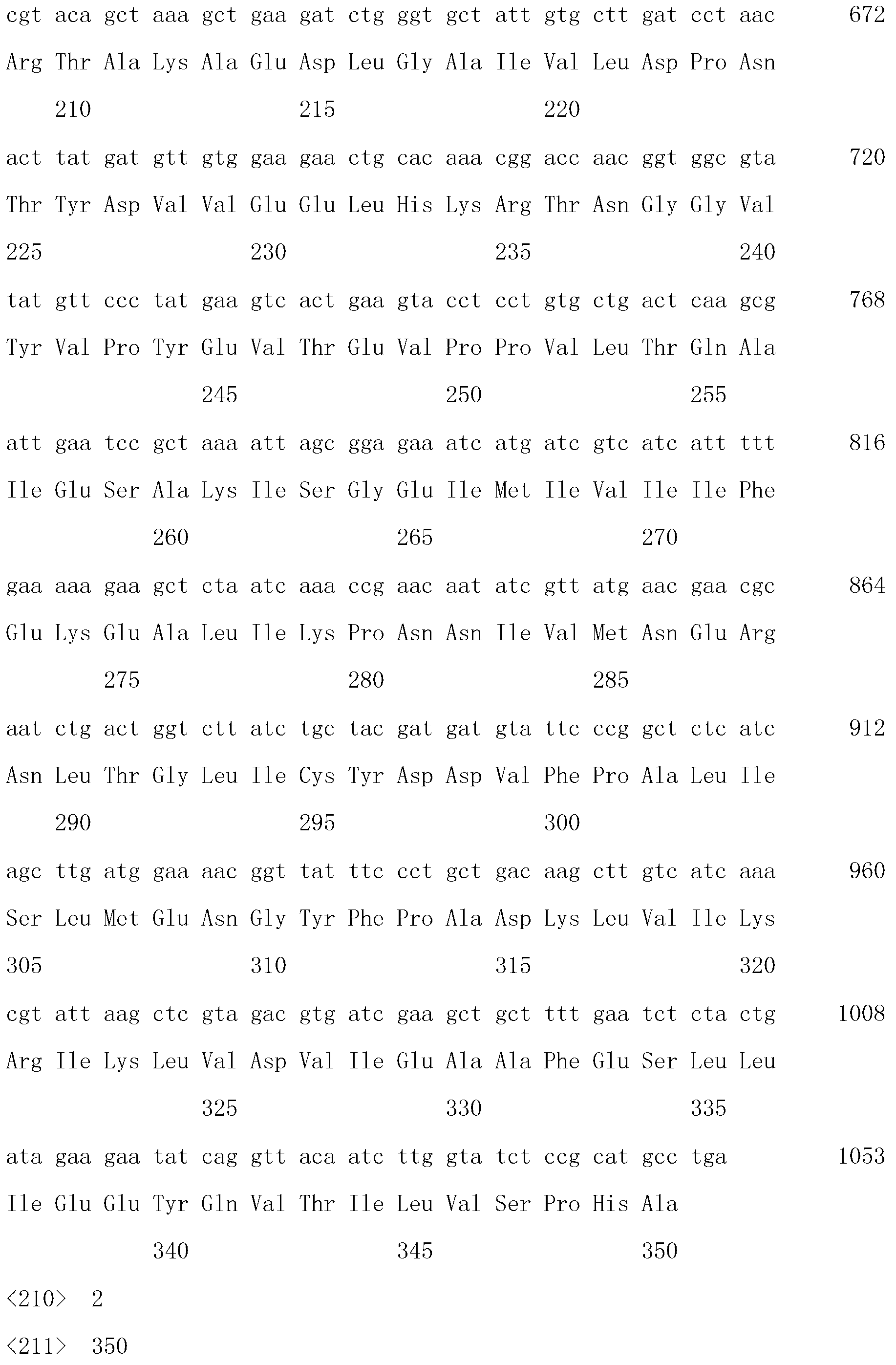

Genetically engineering bacterium capable of producing S-3-hydroxy-butanone as well as construction method and application thereof

InactiveCN103060255AImprove utilizationImprove conversion rateBacteriaMicroorganism based processesEnzyme GeneInulin

The invention discloses a genetically engineering bacterium capable of producing S-3-hydroxy-butanone as well as a construction method and application thereof. The bacterial strain is classified and named as paenibacillus polymyxa CGMCC 3044-Bud A<->. Bud A is a 2,3-butanediol dehydrogenase gene, and the Bud A gene in P. polymyxa CGMCC 3044 is knocked out through homologous double-crossover to obtain the bacterial strain p. polymyxa CGMCC 3044-Bud A<-1>. The recombinant bacterium constructed by the method can be used for fermenting and synthesizing optically pure S-3-hydroxy-butanone, the optical purity of which can reach 100%; reduction-state byproduct 2,3-butanediol of the 3-hydroxy-butanone is not generated; the bacterial strain can be produced by directly using substrates such as jerusalem artichoke and inulin, glucose and butanedione; the construction method has the advantages of being extensive in culture conditions, convenient and simple to operate and beneficial to large-scale industrial production; and the bacterial strain has high optical purity and is low in production cost.

Owner:YANCHENG INST OF TECH

Gene recombination bacterium and application thereof in preparing chiral pure acetoin and 2,3-butanediol

InactiveCN101565685BLow costEasy to operateBacteriaMicroorganism based processesEnzyme GeneRecombinant escherichia coli

The invention discloses an E. coli BL21(pETDuet-ydjLnox) containing a 2R,3R-butanediol dehydrogenase gene ydjL and an NADH oxidase gene nox, wherein the strain is preserved in the 'China Center for Type Culture Collection' on December 23 in 2008, and the preservation number is CCTCC NO: M 208259. The invention also discloses application of a gene recombination bacterium in producing chiral S-AC bycatalyzing meso-BD, producing chiral R-AC by catalyzing 2R,3R-BD and producing chiral pure 2S,3S-BD by splitting a 2,3-BD mixture. The concentration of a chiral AC prepared from the recombinant E. coli can reach over 6 grams per liter (the ee value is more than or equal to 96 percent); and the ee value of the chiral pure 2S,3S-BD is more than or equal to 98 percent, and the regeneration of a cofactor is achieved, thus the gene recombination bacterium has great industrial application prospect.

Owner:SHANDONG UNIV

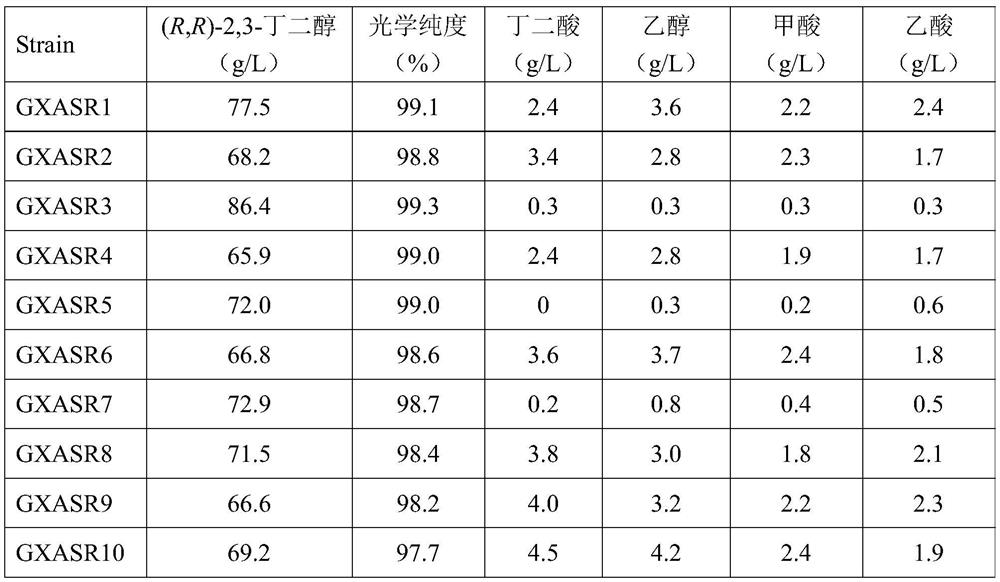

Construction method and application of gene engineering strain for producing (R,R)-2,3-butanediol

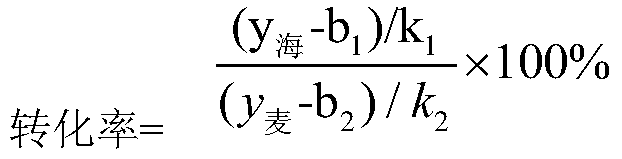

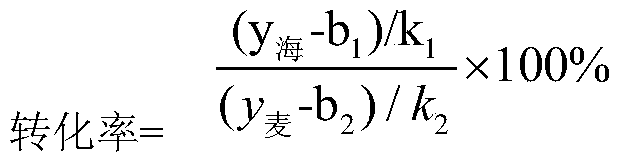

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

Method for fermenting to produce acetoin by utilizing bacillus licheniformis engineered strain

ActiveCN109486871AReduce outputIncrease productionBacteriaMicroorganism based processesBiotechnologyLactate dehydrogenase

The invention discloses a method for fermenting to produce acetoin by utilizing a bacillus licheniformis engineered strain. The method comprises the following steps: knocking out glycerol dehydrogenase genes gdh and 2,3-butanediol dehydrogenase genes budC by taking bacillus licheniformis 10-1-A as an original strain, replacing lactic dehydrogenase genes ldh with NADH oxidase genes nox in Thermococcus profundus DT5432, and constructing a bacillus licheniformis engineered strain capable of being used for producing acetoin; taking glucose as a substrate, biologically fermenting the strain, and preparing the acetoin from fermentation liquor. Experiments prove that the engineered strain disclosed by the invention is capable of producing 82.14g / L of acetoin, and the production efficiency reaches2.28g / L per hour. Moreover, the cost in the production process is low, the yield is high, and the method has excellent application value and considerable economic benefits.

Owner:山东大学深圳研究院 +1

(2R, 3R)-2,3-butanediol dehydrogenase and coding gene and application thereof

The invention discloses (2R, 3R)-2,3-butanediol dehydrogenase from paenibacillus polymyxa ATCC12321 and a coding gene and application thereof. Zymology verifies that the dehydrogenase has new characteristics: (2R, 3R)-2,3-butanediol is catalyzed to generate (R)-acetoin and meso-2,3-butanediol is catalyzed to generate (S)-acetoin by taking NAD+ as coenzyme, and the (R)-acetoin is catalyzed to generate (2R, 3R)-2,3-butanediol, the (S)-acetoin is catalyzed to generate meso-2,3-butanediol, and butanedione is catalyzed to generate (R)-acetoin by taking NADH as coenzyme. Moreover, the dehydrogenasesubstrate has high specificity and wide industrial application prospect.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Meso-2, 3-butanediol dehydrogenase as well as mutant and application thereof

ActiveCN114703156AImprove high temperature resistanceHigh optical purityBacteriaBiofuelsButanediolMutant

The invention discloses meso-2, 3-butanediol dehydrogenase as well as a mutant and application of the meso-2, 3-butanediol dehydrogenase, and the amino acid sequence of the meso-2, 3-butanediol dehydrogenase is as shown in SEQ ID NO. 1. The meso-2, 3-butanediol dehydrogenase with high temperature resistance is found, the meso-2, 3-butanediol dehydrogenase is used as a basis, a product release process is dynamically described through an accelerated sampling molecular dynamics simulation method, the problem that high stability and high activity cannot be considered at the same time is solved, a mutant capable of catalytically preparing meso-2, 3-butanediol is obtained, and the meso-2, 3-butanediol dehydrogenase can be used for preparing the meso-2, 3-butanediol. The mutant has very good high temperature resistance. And after heat treatment at 100 DEG C for 30 minutes, the residual enzyme activity is 23.9%. When the mutant catalyzes acetoin to form meso-2, 3-butanediol, the activity is improved by about 2-5 times. The meso-2, 3-butanediol obtained by the reaction has extremely high optical purity, and a wide application prospect is provided for the production of the meso-2, 3-butanediol through bioconversion.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

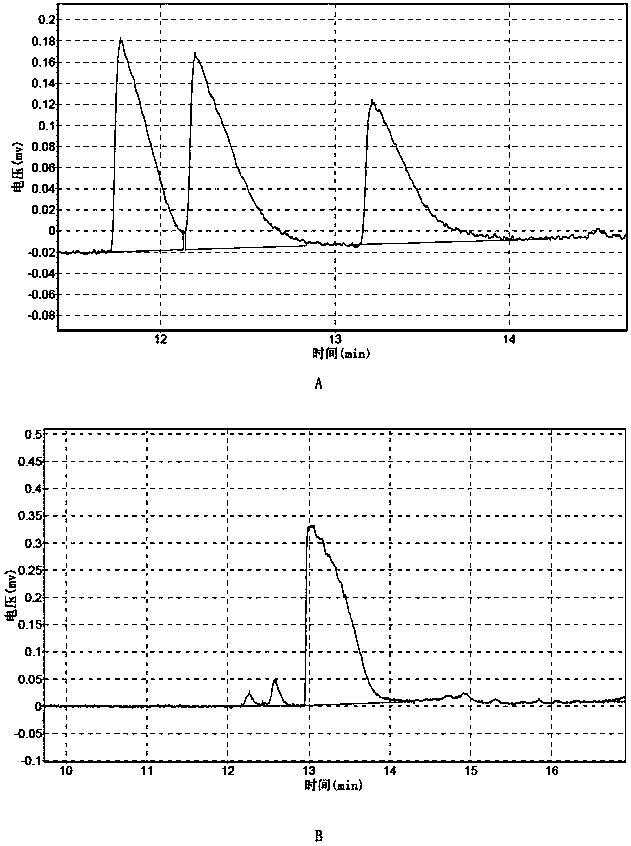

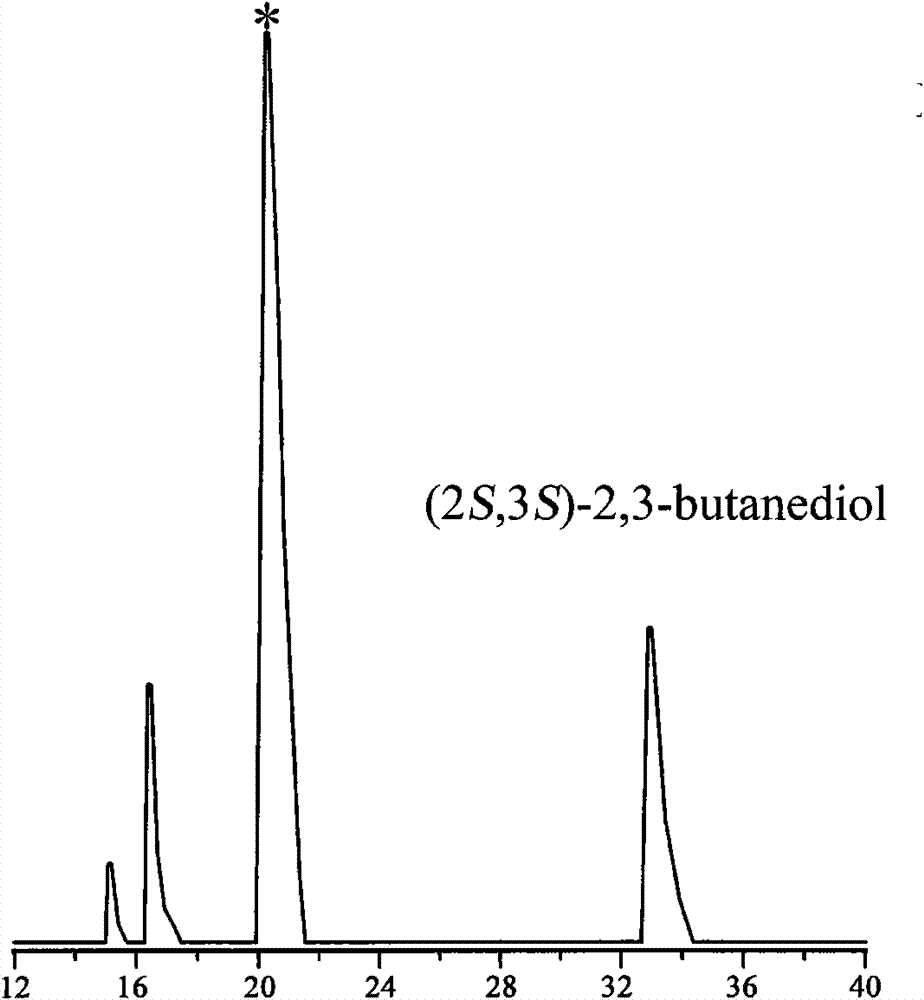

Method for producing chiral pure (2S,3S)-2,3-butanediol

ActiveCN102154384BAchieve regenerationLow costMicroorganism based processesFermentationEscherichia coliRecombinant escherichia coli

The invention discloses a method for producing chiral pure (2S,3S)-2,3-butanediol, which is to express a (2S,3S)-2,3-butanediol dehydrogenase gene in Escherichia coli, and perform the conversion production of chiral pure (2S,3S)-2,3-butanediol by using the recombinant Escherichia coli full cell as a biocatalyst and diacetyl and glucose as a substrate. In the method disclosed by the invention, a culture medium required by the strain is simple and low in cost, and the production process and product separation are convenient. The highest yield of the produced chiral pure (2S,3S)-2,3-butanediol reaches over 26gL<-1>, the ee value is more than 99 percent, and the method has a promotion and application value and can create considerable economic benefit.

Owner:上海肆芃科技有限公司

A 2,3-butanediol dehydrogenase mutant with improved enzyme activity and its construction method

ActiveCN108060145BHigher than vitalityHigh catalytic efficiencyBacteriaMicroorganism based processesBiotechnologyButanediol

The invention discloses an enzyme activity improved 2,3-butanediol dehydrogenase mutant and an establishment method thereof and belongs to the technical field of genetic engineering. According to themutant disclosed by the invention, the 52nd proline is mutated into lysine on the basis of amino acid as shown in SEQ ID No.2. The enzyme activity of the mutant disclosed by the invention is improvedby 68% when being compared with that before mutation, and the industrial application potential of the enzyme is improved.

Owner:JIANGNAN UNIV

A genetically engineered bacterium for realizing high-density fermentation and co-production of 2,3-butanediol, its construction method and application

The invention discloses a genetically engineered bacterium for realizing high-density fermentation and co-production of 2,3-butanediol, and a construction method and application thereof. Key enzyme genes: α-acetolactate synthase encoding gene, α-acetolactate decarboxylase encoding gene and 2,3-butanediol dehydrogenase encoding gene are integrated into the chromosome of Escherichia coli and constructed. The product acetic acid is reduced, so that it can realize high-density fermentation and co-produce high value-added 2,3-butanediol; in addition, the invention also discloses a method for realizing high-density fermentation and co-producing other compounds and 2,3-butanediol. ‑Butanediol genetically engineered bacteria and its application, in addition to high-density fermentation to produce 2,3‑butanediol, it can also co-produce polyhydroxy fatty acid or functional protein, so as to realize polyhydroxy fatty acid or functional protein, and 2,3‑ The low-cost and high-efficiency co-production of butanediol has important industrial application value.

Owner:NANJING TECH UNIV

Construction method and application of genetic engineering strain for producing (r,r)-2,3-butanediol

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

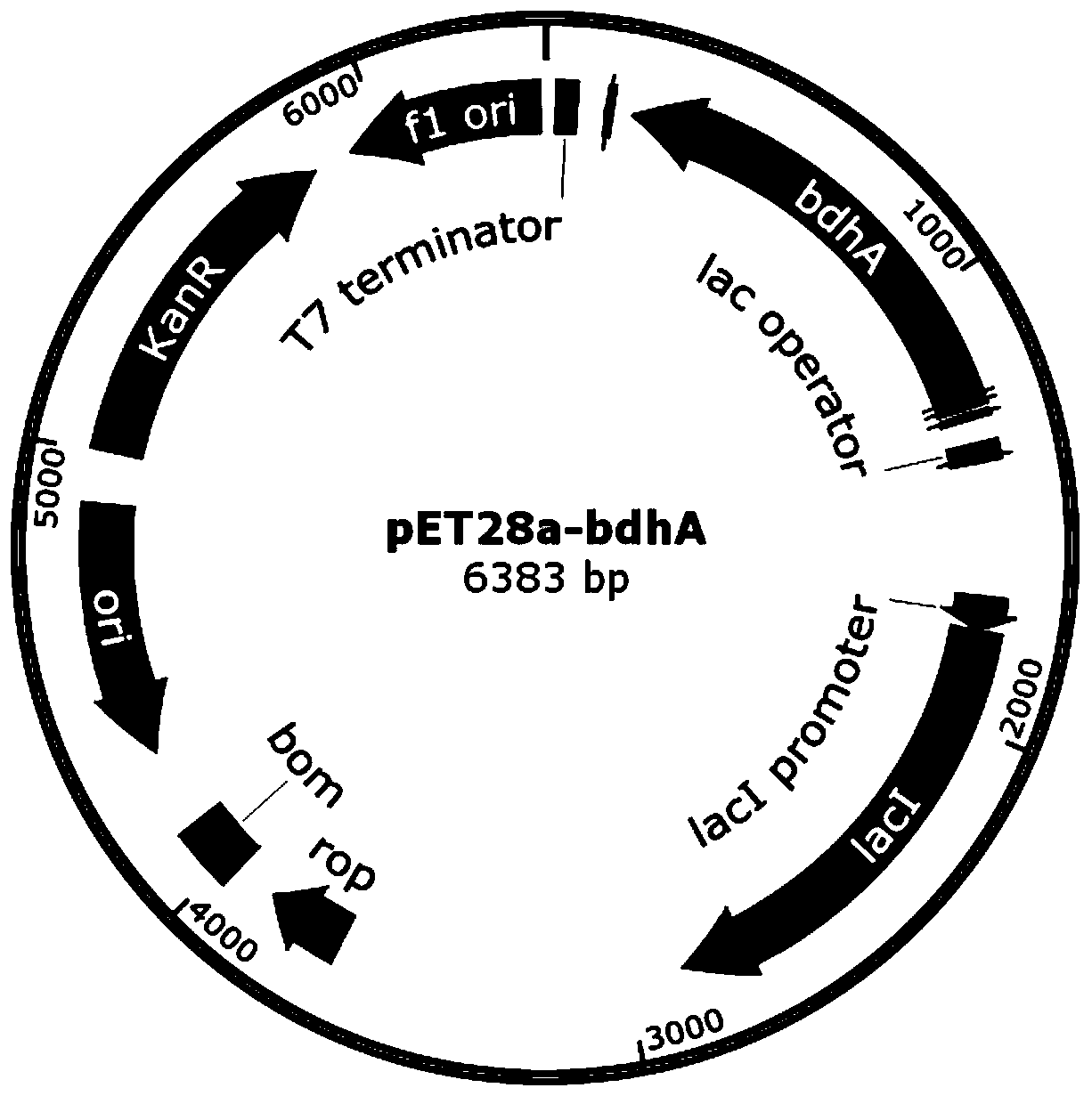

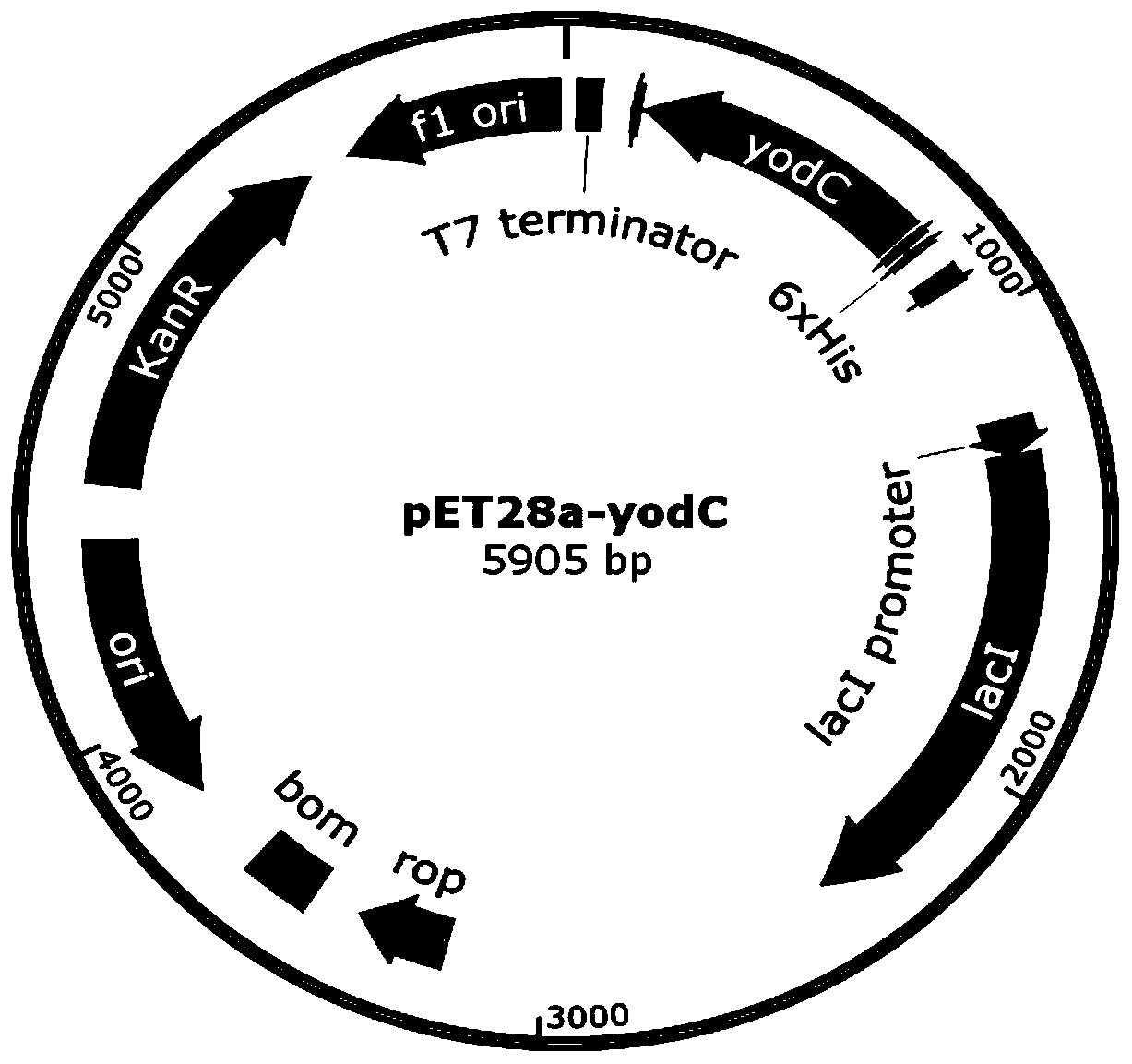

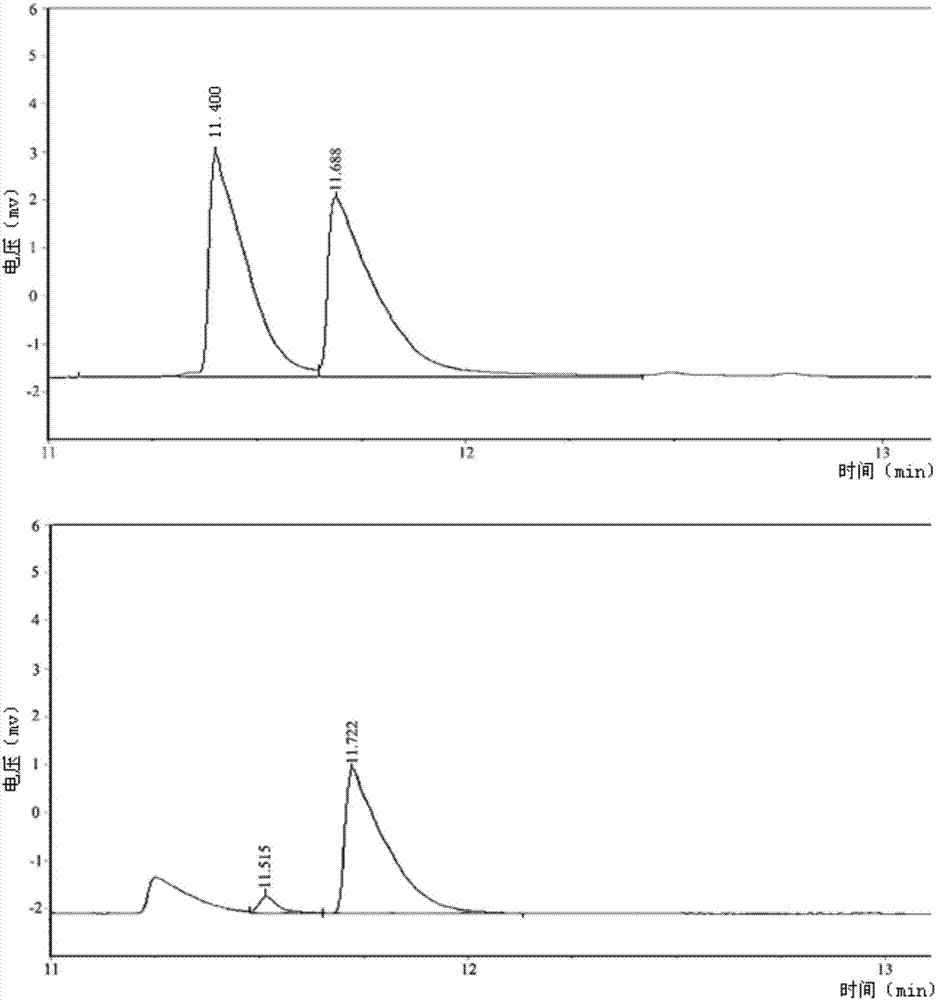

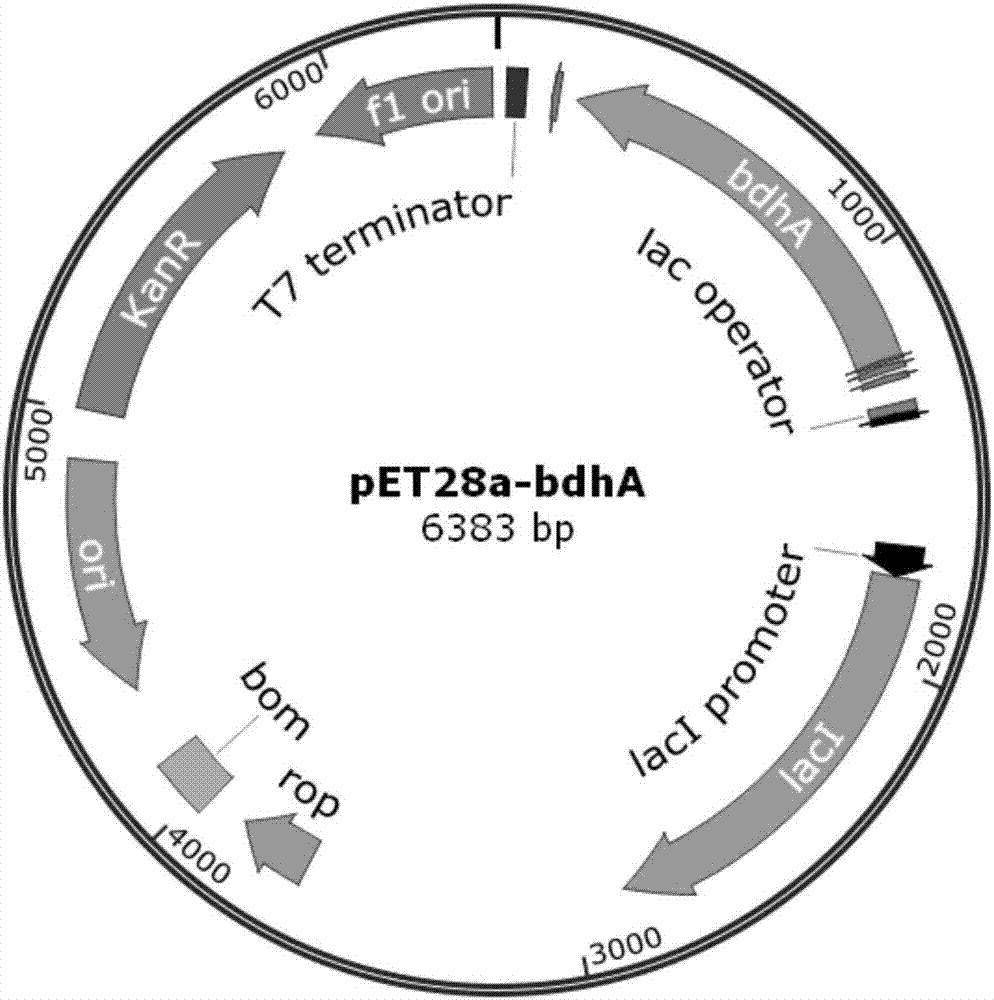

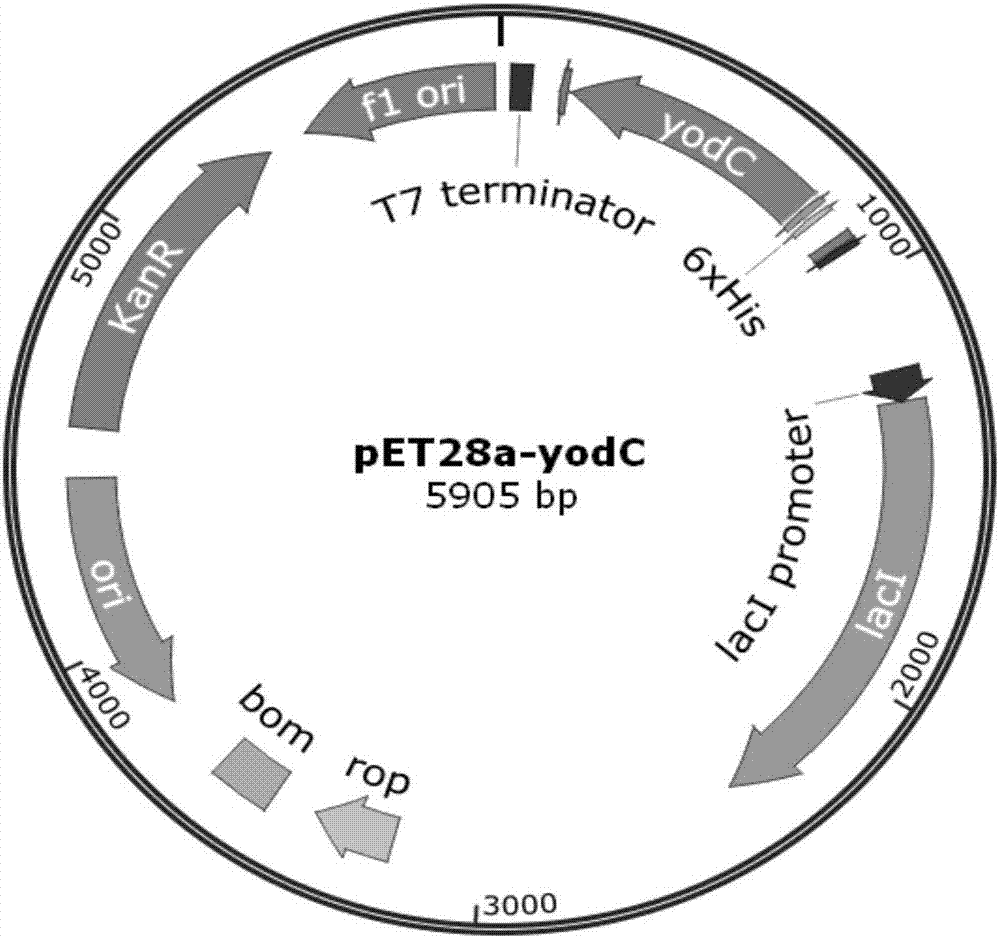

A kind of method for producing l(+)-acetoin by enzymatic reaction in vitro

ActiveCN106967741BAchieve in vitro productionEfficient productionBacteriaMicroorganism based processesEscherichia coliOxidative enzyme

The invention discloses a method for generating L(+)-acetoin by in-vitro enzyme reaction. The method comprises the following steps: (1) connecting a carrier pET28a with 2,3-butanediol dehydrogenase coding gene bdhA to obtain pET28a-bdhA, and importing escherichia coli, fermenting, purifying, and concentrating to obtain 2,3-butanediol dehydrogenase concentrated solution; connecting a carrier pET28a with NADH oxidase coding gene yodC to obtain pET28a-yodC, and importing the escherichia coli, fermenting, purifying, and concentrating to obtain NADH oxidase concentrated solution; and (2) uniformly mixing the 2,3-butanediol dehydrogenase concentrated solution, the NADH oxidase concentrated solution, meso-2,3-butanediol, NAD+ and FAD+, reacting to obtain the L(+)-acetoin. The method is capable of using the cheap meso-2,3-butanediol as a substrate, and realizing the in-vitro generation of the L(+)-acetoin with high added value. The yield and purity are high.

Owner:TIANJIN UNIV

Enzyme activity improved 2,3-butanediol dehydrogenase mutant and establishment method thereof

ActiveCN108060145AHigher than vitalityHigh catalytic efficiencyBacteriaMicroorganism based processesMutantGenetic engineering

The invention discloses an enzyme activity improved 2,3-butanediol dehydrogenase mutant and an establishment method thereof and belongs to the technical field of genetic engineering. According to themutant disclosed by the invention, the 52nd proline is mutated into lysine on the basis of amino acid as shown in SEQ ID No.2. The enzyme activity of the mutant disclosed by the invention is improvedby 68% when being compared with that before mutation, and the industrial application potential of the enzyme is improved.

Owner:JIANGNAN UNIV

Construction method and application of optically pure meso-2,3-butanediol high-yield engineering strain

The invention discloses construction of a high-yield engineering strain for optically pure meso-2,3-butanediol. A construction method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and a meso-2,3-butanediol dehydrogenase gene, afterwards, splicing to obtain a gene cluster containing the three genes, then introducing the gene cluster into an expression vector to obtain a polycistronic recombinant plasmid, and finally introducing the recombinant plasmid into a host bacterium E. coli again, so that a high-yield engineering bacterium is obtained. Synthesis raw materials used by the bacterium are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield, high in production efficiency and good in stability, has the highest yield which can reach 91.5g / L and the optical purity which can reach 99 percent or above. The invention discloses application of the high-yield engineering strain to the production of the optically pure meso-2,3-butanediol by utilizing cheap cassava meal as a carbon source and utilizing cottonseed protein powder, soybean pulp powder, soybean cake powder or peanut protein powder as a nitrogen source at the same time. The production cost is lowered.

Owner:GUANGXI ACAD OF SCI

A method for fermenting and producing acetoin by using Bacillus licheniformis engineered strains

ActiveCN109486871BReduce outputIncrease productionBacteriaMicroorganism based processesBiotechnologyLactate dehydrogenase

The invention discloses a method for fermenting and producing acetoin by using Bacillus licheniformis engineering strains, which uses Bacillus licheniformis 10-1-A as the starting bacteria to knock out its glycerol dehydrogenase gdh gene and 2,3 -Butanediol dehydrogenase gene budC and replace the lactate dehydrogenase gene ldh with the NADH oxidase gene nox from Thermococcus profundus DT5432 to construct an engineered strain of Bacillus licheniformis that can be used to produce acetoin, and then use glucose as the base The bacteria are biologically fermented, and acetoin is obtained from the fermentation broth. Experiments have confirmed that the engineering bacteria of the present invention can produce 82.14 g / L of acetoin, and the production efficiency reaches 2.28 g / L / hour, and the production process has low cost and high yield, and has good application value and considerable economic benefits.

Owner:山东大学深圳研究院 +1

Method for generating L(+)-acetoin by in-vitro enzyme reaction

ActiveCN106967741AAchieve in vitro productionEfficient productionBacteriaMicroorganism based processesEscherichia coliButanediol

The invention discloses a method for generating L(+)-acetoin by in-vitro enzyme reaction. The method comprises the following steps: (1) connecting a carrier pET28a with 2,3-butanediol dehydrogenase coding gene bdhA to obtain pET28a-bdhA, and importing escherichia coli, fermenting, purifying, and concentrating to obtain 2,3-butanediol dehydrogenase concentrated solution; connecting a carrier pET28a with NADH oxidase coding gene yodC to obtain pET28a-yodC, and importing the escherichia coli, fermenting, purifying, and concentrating to obtain NADH oxidase concentrated solution; and (2) uniformly mixing the 2,3-butanediol dehydrogenase concentrated solution, the NADH oxidase concentrated solution, meso-2,3-butanediol, NAD+ and FAD+, reacting to obtain the L(+)-acetoin. The method is capable of using the cheap meso-2,3-butanediol as a substrate, and realizing the in-vitro generation of the L(+)-acetoin with high added value. The yield and purity are high.

Owner:TIANJIN UNIV

Bacillus subtilis strain for producing high-purity chiral meso-2,3-butanediol as well as construction method and application of strain

ActiveCN103451141BIncrease productionHigh yieldBacteriaMicroorganism based processesAcetic acidAcetoin reductase

The invention discloses a bacillus subtilis strain for producing high-purity chiral meso-2,3-butanediol as well as a construction method and application of the strain. The construction method comprises the steps of knocking out an acoA gene of a direct substrate of 2,3-butanediol, acetoin in a degradation pathway, from bacillus subtilis, knocking out an acetoin reductase coding gene bdhA, knocking out a pta gene in a byproduct acetic acid formation path and knocking out a 1dh gene in a byproduct lactic acid formation path, over-expressing a synthesis branch a1sSD promoter through a P43 strong promoter, over-expressing meso-2,3-butanediol dehydrogenase coding gene budC through a P43 strong promoter, and over-expressing a transhydrogenase coding gene udhA in a reducing force equilibrium process through a P43 strong promoter. The constructed bacillus subtilis engineering strain is safe and harmless, and can produce meso-2,3-butanediol with chiral purity greater than 99% by taking glucose as a substrate.

Owner:TIANJIN UNIV

Mutant strain for increasing content of ethanol produced by fermentation of synthesis gas and application of mutant strain

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

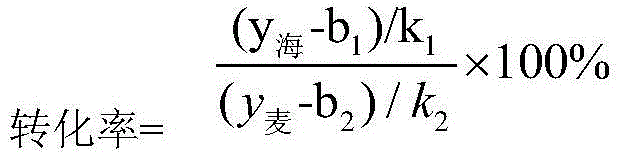

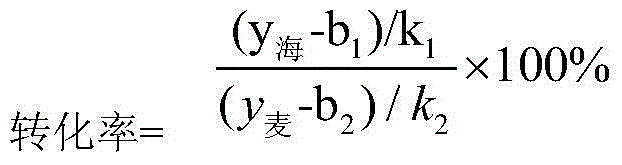

Genetically engineered bacterium for efficiently producing (2S, 3S)-2, 3-butanediol, construction method and application thereof

PendingCN114075526AIncrease concentrationIncrease productionBacteriaMicroorganism based processesStaphylococcus aureusButanediol

The invention relates to a genetically engineered bacterium for efficiently producing (2S, 3S)-2, 3-butanediol, a construction method and application thereof. According to the invention, based on escherichia coli, a new genetically engineered bacterium is constructed, and simultaneously expresses 2, 3-butanediol dehydrogenase in staphylococcus aureus and klebsiella pneumoniae, or simultaneously expresses 2, 3-butanediol dehydrogenase in staphylococcus aureus and corynebacterium glutamicum, or simultaneously expresses 2, 3-butanediol dehydrogenase in klebsiella pneumoniae and corynebacterium glutamicum; and through the synergistic effect of the double enzymes, accumulation of diacetyl in cells is reduced, and conversion of the diacetyl into the (2S, 3S)-2, 3-butanediol is enhanced, so that the concentration of a substrate is increased, and the conversion rate of the substrate is increased so as to increase the yield of the (2S, 3S)-2, 3-butanediol, wherein the yield reaches 7.85 g / L.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com