Genetically engineering bacterium capable of producing S-3-hydroxy-butanone as well as construction method and application thereof

A technology of genetically engineered bacteria and hydroxybutanone is applied in the field of genetically engineered bacteria and its construction, and can solve the problems of high price of meso-2,3-butanediol, serious environmental pollution, and many reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of Jerusalem artichoke inulin crude extract:

[0039] Fresh Jerusalem artichoke is washed and peeled, blanched to eliminate enzymes (100°C, 15min), cut into thin slices, blown and dried at 70°C, and then crushed through an 80-mesh sieve to obtain coarse powder of Jerusalem artichoke, which is stored in the refrigerator for later use. According to the ratio of 1:6, weigh the coarse powder of Jerusalem artichoke into the water, stir evenly, heat and extract in a water bath at 70°C for 4 hours, adjust the pH to 9 with milk of lime, then keep it warm in a water bath at 80°C for 1 hour, and filter it with gauze to obtain the Jerusalem artichoke. Crude powder extract.

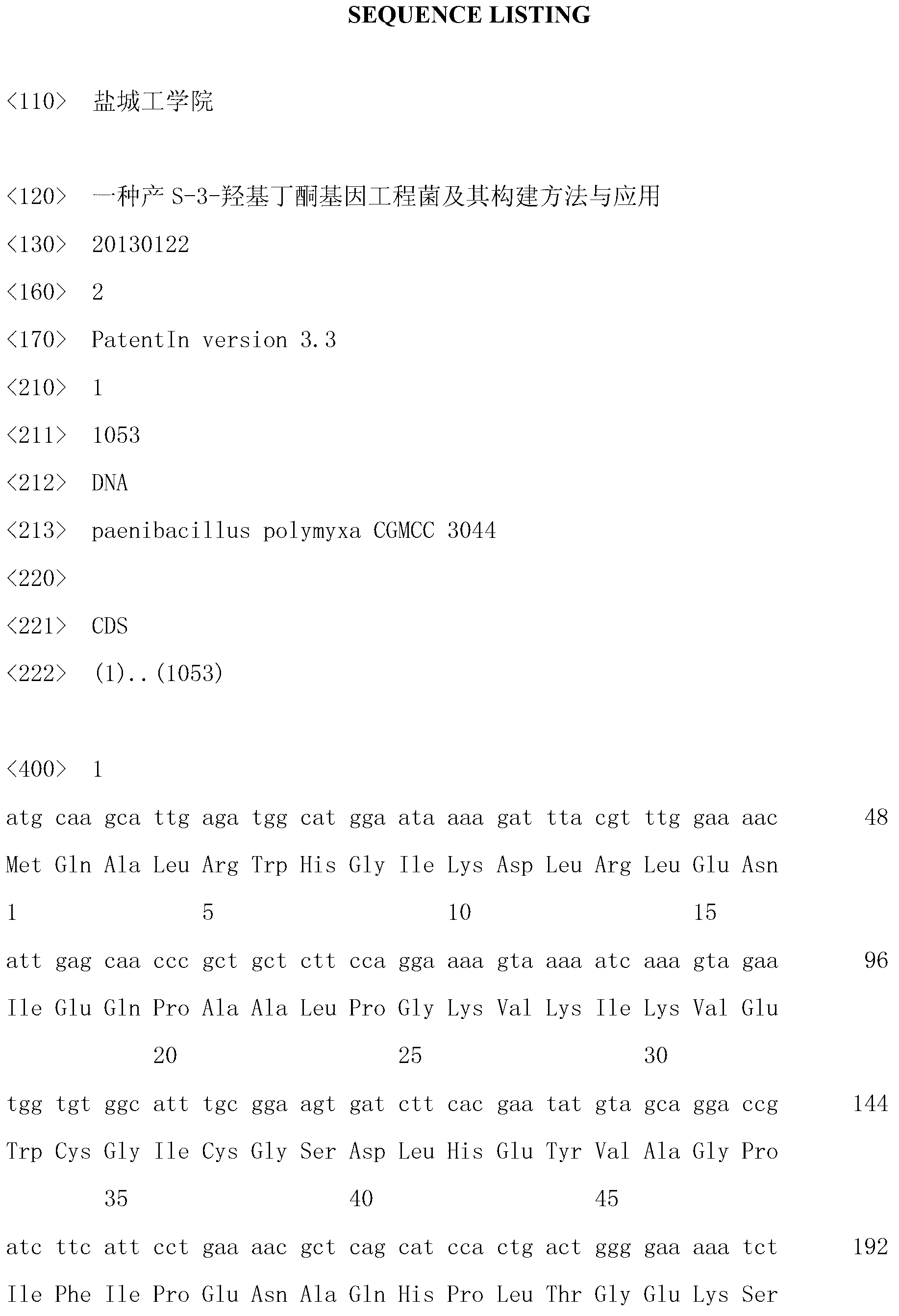

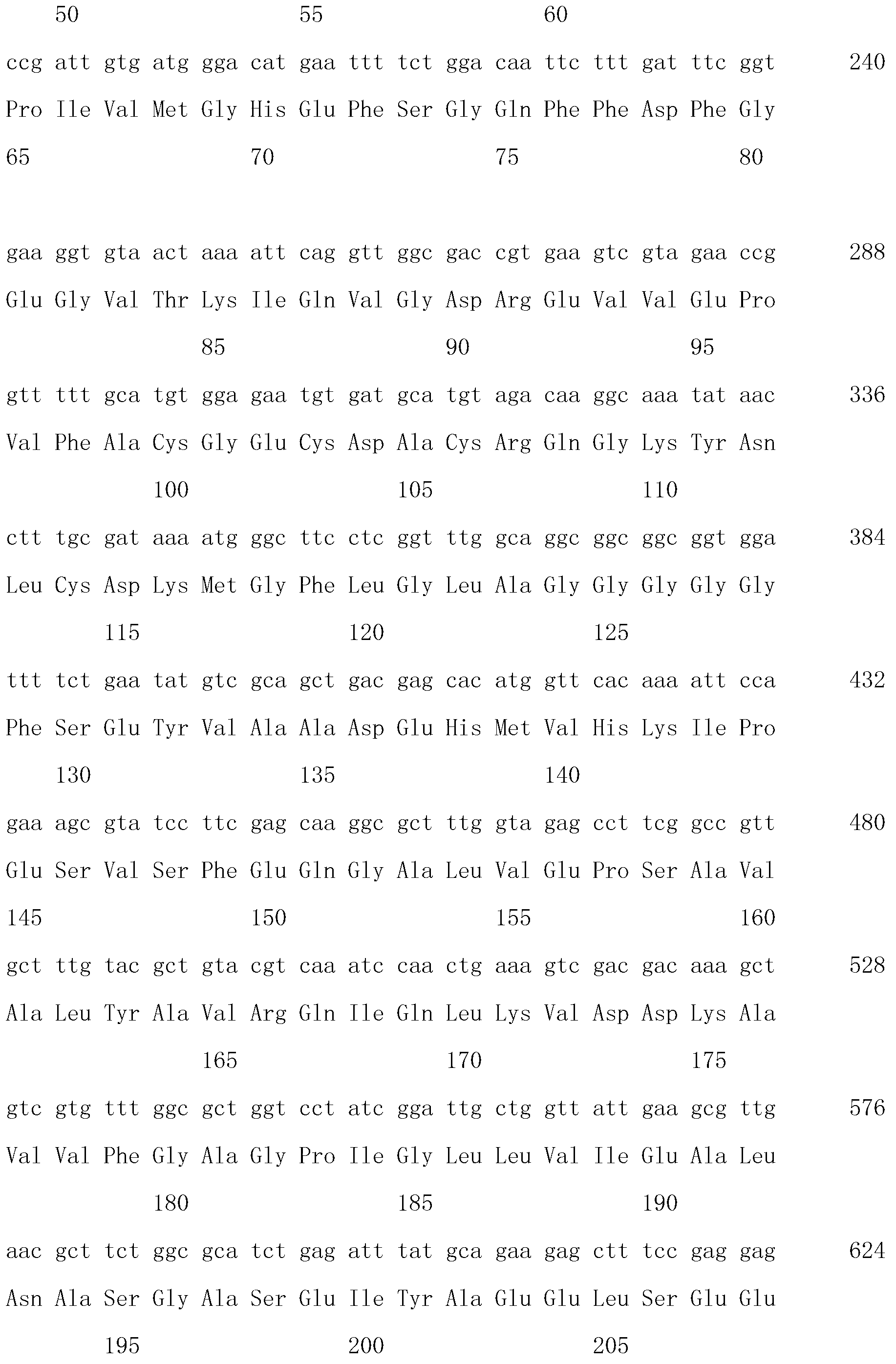

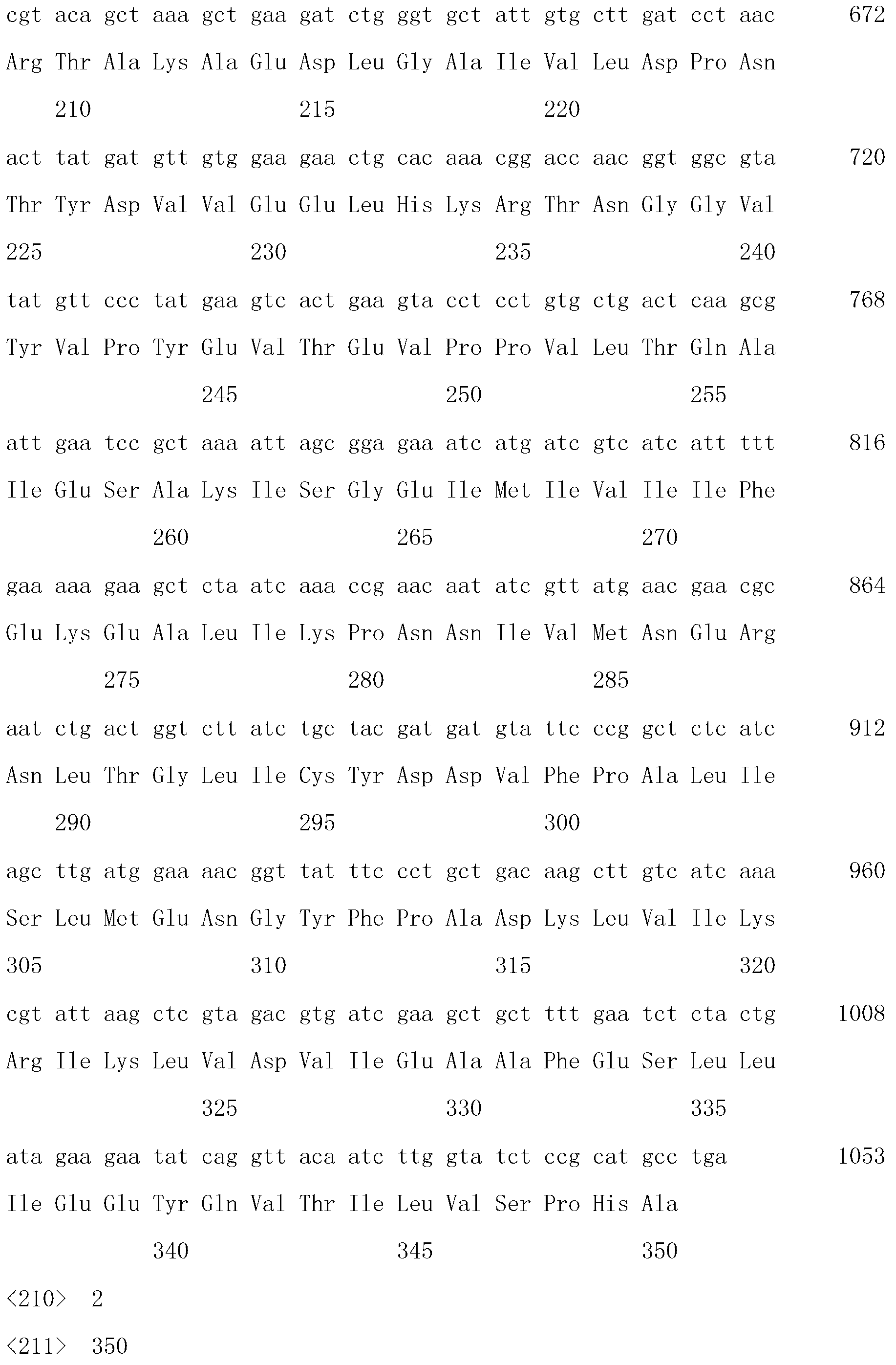

[0040] Embodiment: 2: the cloning of gene Bud A:

[0041] The primers required for synthetic PCR were designed according to the sequence of the Bud A gene in Paenibacillus polymyxa ATCC 12321 published by Genebank:

[0042] P1: 5'-ATGCAAGCATTGAGATGGCA-3'

[0043] P2: 5'-TTAGGCTTTCGGAG...

Embodiment 3

[0045] Example 3: Recombinant cosmid "SuperCos-1 / pIJ790-Bud A homology arm Ⅰ-oriT-Apra R - Construction of Bud A homology arm Ⅱ":

[0046] Introduce EcoR I and Xho I at both ends of the 39bp base sequence at the 5' end of Bud A to obtain the homology arm I of Bud A; introduce Not I at both ends of the approximately 20bp base sequence at the 3' end of Bud A , BamH I, to get the Bud A homology arm II. The oriT replication initiation sequence and the apramycin resistance gene Apramycin were connected to the clone cosmid SuperCos-1 / pIJ790 according to the restriction site R The two ends of the sequence were obtained containing "Bud A homology arm Ⅰ-oriT-Apra R - The recombinant cosmid SuperCos-1 / pIJ790 of the Bud A homology arm II" sequence and the λRed sequence.

Embodiment 4

[0047] Example 4: Recombinant cosmid "SuperCos-1 / pIJ790-Bud A homology arm Ⅰ-oriT-Apra R -Bud A Homology Arm II" was transformed into Paenibacillus polymyxa CGMCC 3044.

[0048] The recombinant cosmid SuperCos-1 / pIJ790-"SuperCos-1 / pIJ790-Bud A homology arm Ⅰ-oriT-Apra R -Bud A Homologous Arm II" was transformed into Paenibacillus polymyxa polymyxa CGMCC 3044, spread on a plate containing 40 μg / mL apramycin, picked positive recombinants, and carried out colony PCR identification to obtain recombinant Paenibacillus polymyxa Bacillus named paenibacillus polymyxa CGMCC 3044-Bud A - .

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com