Genetically engineered bacteria realizing high-density fermentation co-production of 2,3-butanediol as well as construction method and application thereof

A technology of high-density fermentation and genetically engineered bacteria, applied in the field of biochemical industry, can solve the problems of inability to reduce the accumulation of acetic acid, prolong the fermentation cycle, treat the symptoms but not the root cause, and achieve the effects of shortening the production cycle, reducing production costs, and strengthening separation and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

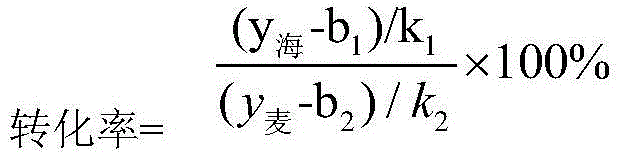

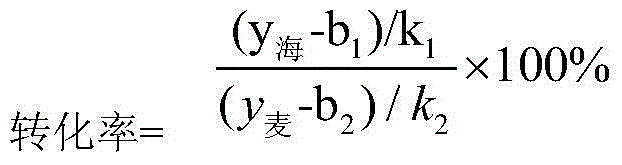

Method used

Image

Examples

Embodiment 1

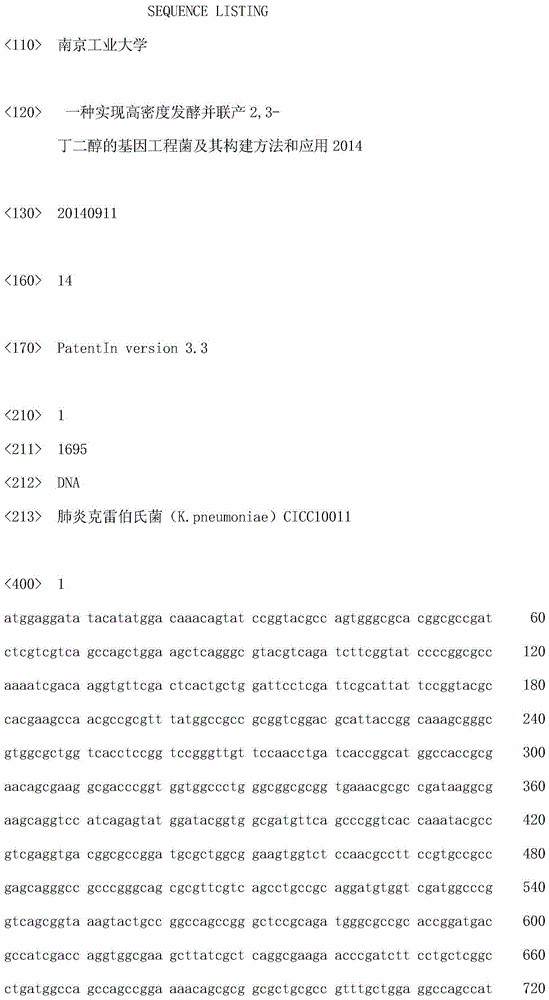

[0040] Example 1 Construction of Genetically Engineered Bacteria Realizing High-Density Fermentation and Co-production of (R,R)-2,3-Butanediol

[0041] 1. Cloning of α-acetolactate synthase gene alsS, α-acetolactate decarboxylase gene budA and (R,R)-2,3-butanediol dehydrogenase gene bdhA

[0042] (1) Cloning of alsS gene encoding α-acetolactate synthase

[0043] Synthetic primers were designed according to the alsS gene sequence in Klebsiella pneumoniae (K.pneumoniae) published by Genebank:

[0044] P1: 5'-GATATGGACAAACAGTATCCGGT-3'

[0045] P2: 5'-GCGTTACAGAATCTGACTCAGAT-3'

[0046] Using the genomic DNA of K.pneumoniae CICC10011 as a template, using primers P1 and P2, Takara high-fidelity enzyme HS (Premix) PCR amplified alsS gene.

[0047] PCR reaction system: HS (Premix) 25 μL, primer P10.3 μL, primer P20.3 μL, K.pneumoniae CICC10011 genome 0.4 μL, ddH 2 O 24 μL.

[0048] PCR reaction conditions: 98°C for 10s, 62°C for 15s, 72°C for 1min45s, cycle 30 times; 72°C f...

Embodiment 2

[0169] Example 2 High-density fermentation implementation of the genetically engineered bacteria-recombinant Escherichia coli LG-R in Example 1 to produce (R,R)-2,3-butanediol strains: Escherichia coli MG1655, Escherichia coli LG-R;

[0170] Seed medium (g / L): peptone 10; yeast extract 5; NaCl 10.

[0171] Fermentation medium (g / L): glucose 80; K 2 HPO 4 ·3H 2 O 13.7; KH 2 PO 4 2.0; (NH 4 ) 2 HPO 4 3.3; (NH 4 ) 2 SO 4 6.6; MgSO 4 ·7H 2 O 0.25; FeSO 4 ·7H 2 O 0.05; ZnSO 4 ·7H 2 O 0.01; MnSO 4 ·H 2 O 0.01; CaCl 2 0.01; EDTA 0.05.

[0172] Fermentation conditions:

[0173] Preparation of seed solution: transfer the strains preserved in glycerol tubes to fresh LB liquid medium, activate at 37°C and 200rpm for 16h; connect 1 ring of activated strains to LB solid medium with corresponding antibiotics, and culture at 37°C for 12h Pick a single bacterium colony from the fresh flat plate in the 250mL Erlenmeyer flask that 50mL seed medium is housed, cultivate 12...

example 3

[0179] Example 3 realizes high-density fermentation and co-production of meso-2, the construction of genetically engineered bacteria of 3-butanediol

[0180] 1. Amplify the operon gene fragment alsSbudAbudC of the gene encoding α-acetolactate synthase, the gene encoding α-acetolactate decarboxylase and the gene encoding meso-2,3-butanediol dehydrogenase

[0181] Using the genomic DNA of K.pneumoniae CICC10011 as a template, using primers P15 and P16, Takara high-fidelity enzyme HS (Premix) was used for PCR amplification, and the amplified fragments included: promoter, RBS site, alsS, budA, budC and terminator.

[0182] P15: 5'-ACCTATTGACAATTAAAGGCTAAAATGCTATAATTCCACAAATCGGAGGATATACATATGAATCATTCTGCTGAATG-3'

[0183] P16: 5'-AAAAGGCCATCCGTCAGGATGGCCTTCTTTAGTTAAATACCATCCCGC-3'

[0184] PCR reaction system: HS (Premix) 25μL, primer P150.3μL, primer P160.3μL, K.pneumoniae CICC10011 genome 0.4μL, ddH 2 O 24 μL.

[0185] PCR reaction conditions: 98°C for 10s, 58°C for 15s, 72°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com