Method for generating L(+)-acetoin by in-vitro enzyme reaction

A technology of acetoin and in vitro enzyme, which is applied in the field of in vitro enzyme reaction to produce L-acetoin, can solve the problems of many by-products and affect downstream separation, and achieve effective regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

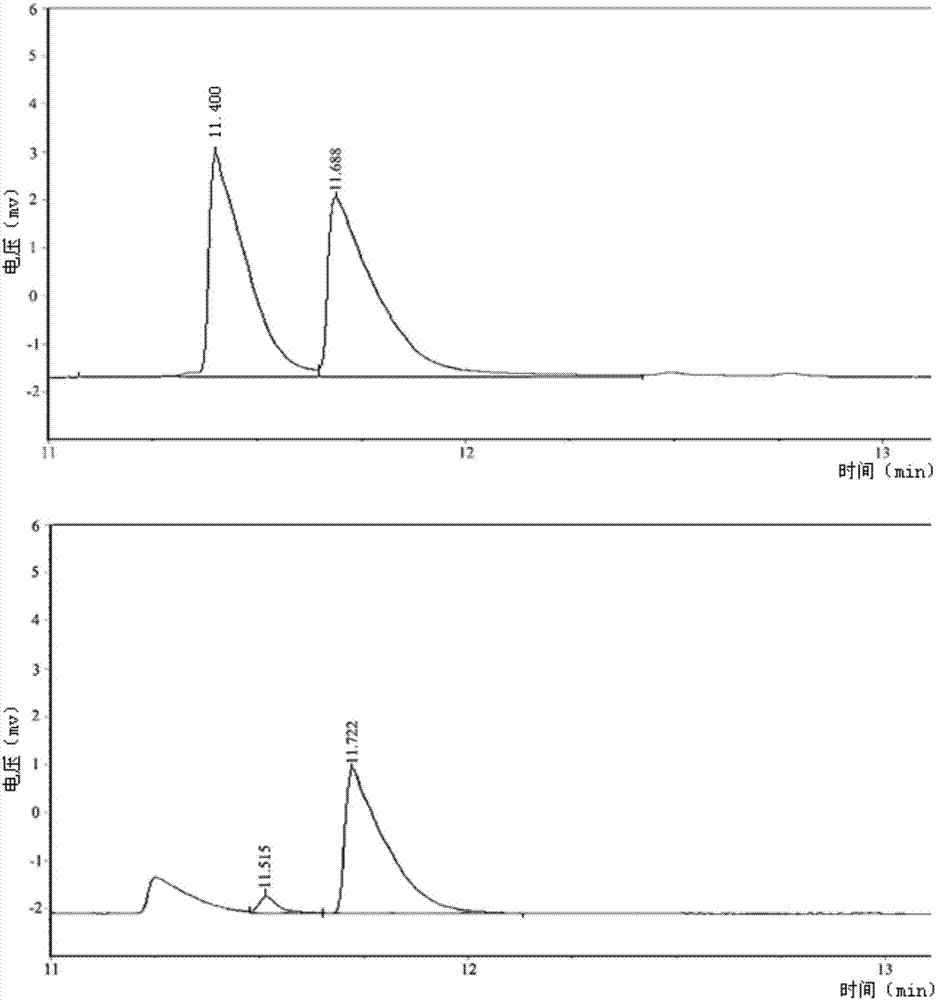

Image

Examples

Embodiment 1

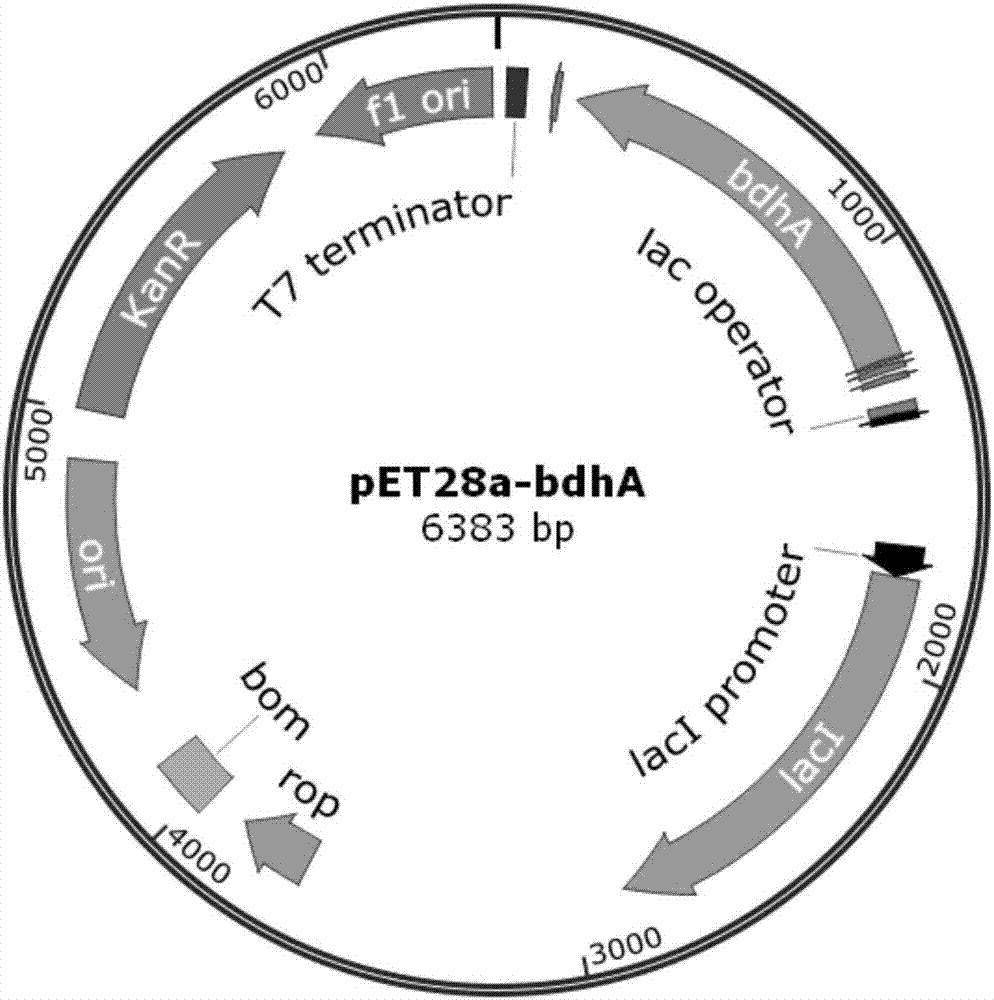

[0027] Example 1 Overexpression of 2,3-butanediol dehydrogenase (bdhA) using commercial protein expression vector pET28a

[0028] Using the Bacillus subtilis B. subtilis 168 genome as a template, primers p-bdhA1 and p-bdhA2 were used to amplify the gene bdhA fragment (about 1.0 kp). The bdhA fragment and the pET28A plasmid were digested with Thermo Fast digest NheI / BamHI, and after ligation and transformation, the expression vector pET28a-bdhA of the bdhA gene was obtained (see figure 1 ), and the sequence detection was correct. The plasmid with the correct sequencing result was transformed into commercially competent E. coli BL21(DE3) by the traditional calcium chloride method to obtain BL21-1 overexpressing 2,3-butanediol dehydrogenase (bdhA).

Embodiment 2

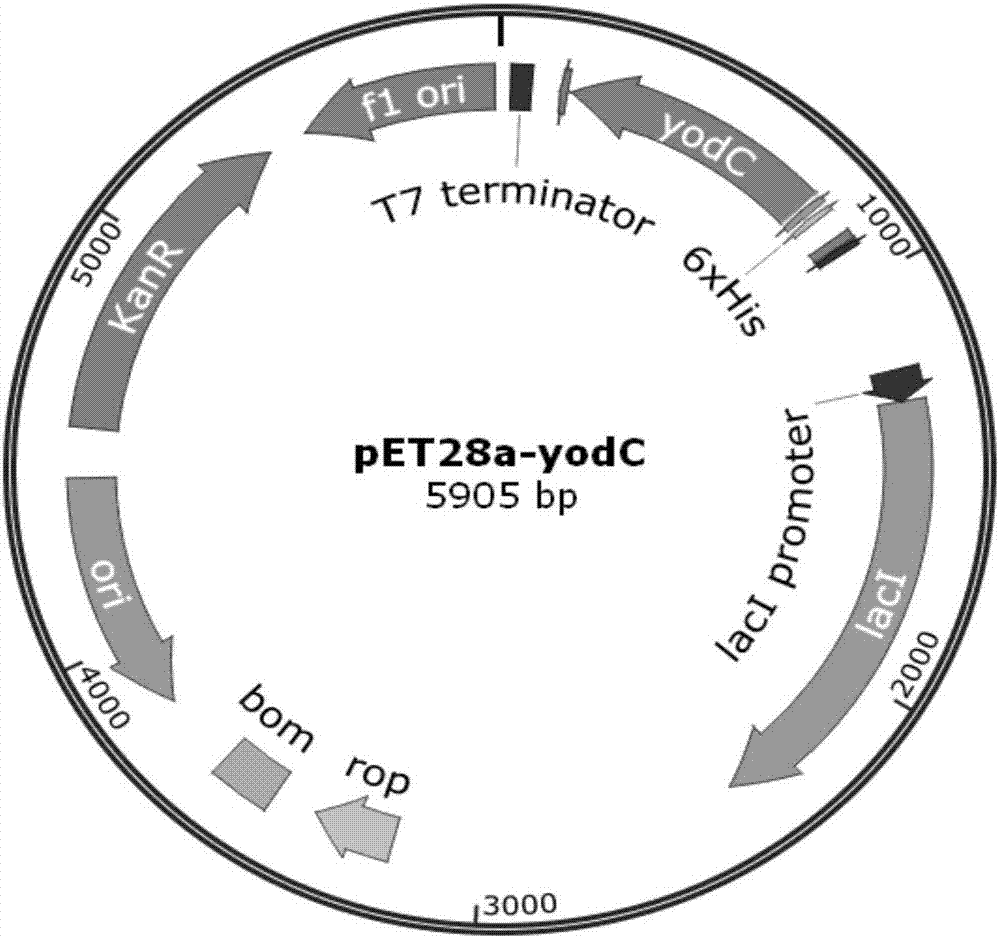

[0029] Example 2 Overexpression of NADH oxidase (yodC) using commercialized protein expression vector pET28a

[0030] Using the Bacillus subtilis B. subtilis 168 genome as a template, primers p-yodC1 and p-yodC2 were used to amplify the gene yodC fragment (609bp). Then the yodC fragment and the pET28a plasmid were digested with Thermo Fast digest NdeI / XhoI, and after ligation and transformation, the expression vector pET28a-yodC of the yodC gene was obtained (see figure 2 ), and the sequence detection was correct. The plasmid with the correct sequencing result was transformed into commercially competent E. coli BL21(DE3) by the traditional calcium chloride method to obtain BL21-2 overexpressing NADH oxidase (yodC).

[0031] Table 1 Primer sequences used for strain construction

[0032]

Embodiment 3

[0033] Example 3 Purification and concentration of 2,3-butanediol dehydrogenase and NADH oxidase

[0034] 1. The specific steps for the purification and concentration of 2,3-butanediol dehydrogenase are:

[0035] 1) Inoculate Escherichia coli BL21-1 into 400mL LB medium, culture on a shaker at 37°C, 220rpm until the OD600 is 0.6, add the inducer IPTG to a final concentration of 0.5mM, culture at 16°C for 12h, centrifuge at 4°C, 4200rpm for 20min Collect the cells and suspend them with 20mL buffer A.

[0036] 2) Collect the suspension of BL21-1 obtained in step 1), break the cells under the action of a high-pressure cell breaker, at 4°C, 1200bar, oil pressure 18Kg / cm 3 Treated 3 times under the same conditions, centrifuged at 4°C and 8000rpm for 30min after crushing, and collected the supernatant to obtain the crude enzyme solution.

[0037] 3) Using the crude enzyme solution obtained in step 2) to purify the protein by using a gravity nickel column purification method. At 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com