An economical 690mpa high-strength steel plate and its preparation method

A high-strength steel plate, economical technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of surface cracks that are not conducive to the hot delivery of the billet, the performance of the core of the steel plate, and the increase in the cost of the Mn alloy, etc., to achieve The effect of shortening lead time, reducing energy consumption cost, and reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to better explain the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples. The following examples are only illustrative technical solutions of the present invention, and do not limit the present invention in any form . The serial numbers of the following embodiments are for description only, and do not represent the advantages and disadvantages of the embodiments.

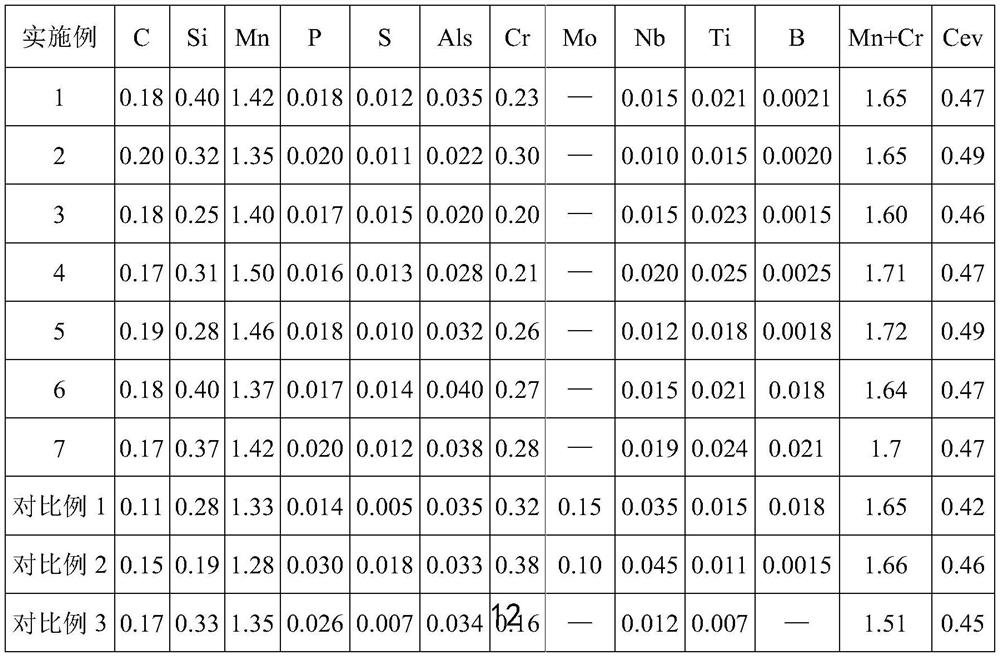

[0060] The following table 1 is a list of chemical composition values of each embodiment of the present invention and comparative examples;

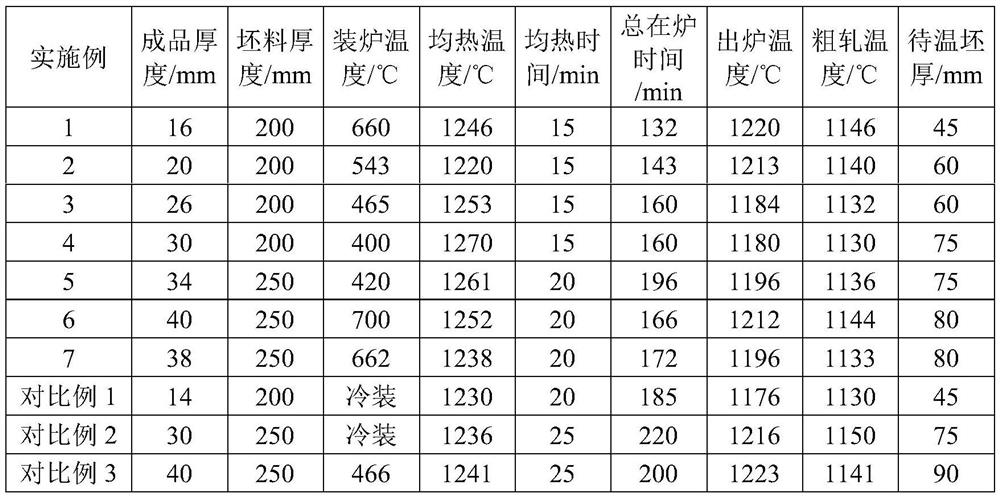

[0061] Table 2 below is the heating and rolling process conditions of each embodiment of the present invention and comparative examples;

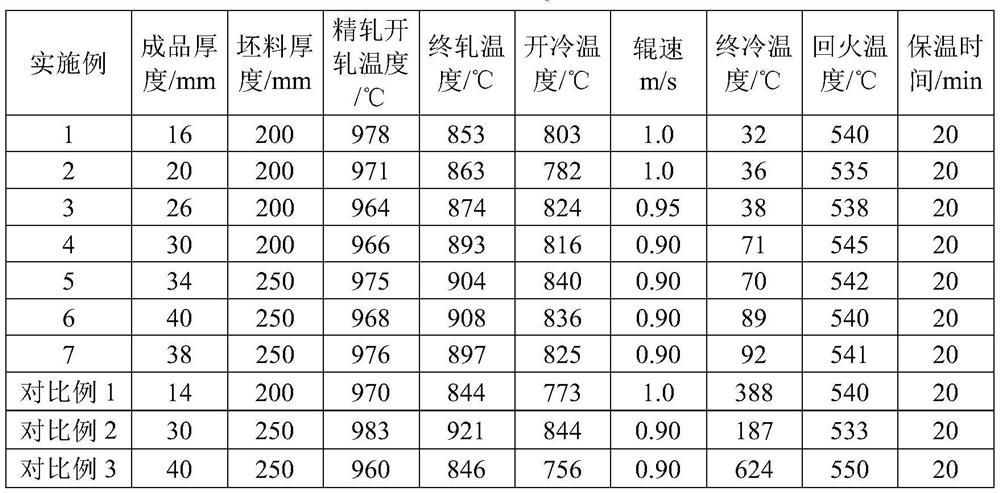

[0062] The following table 3 is the rolling, DQ cooling and heat treatment process conditions of each embodiment of the present invention and comparative examples;

[0063] Table 4 below is a list of the main m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com