High-altitude rotation construction method for large-scale venue steel awning

A construction method and technology of steel cover, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of difficult to meet the installation requirements of steel structure projects, heavy weight of rods, large size of components, etc. The effect of high height, heavy weight and large space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In order to improve the construction efficiency and safety factor of the steel cover of large venues, reduce the amount of high-altitude work, to ensure the quality of construction, the present invention provides a high-risk rotation construction method of large venue steel masks, which combines Figure 1-6 And examples describe the specific embodiments of the present scheme.

[0042] High empty rotation construction method of steel cover of large venues, the steps are as follows:

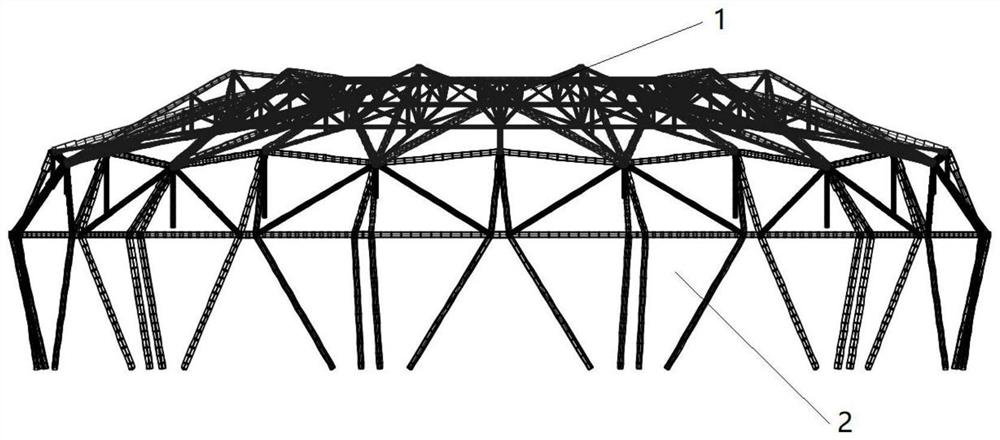

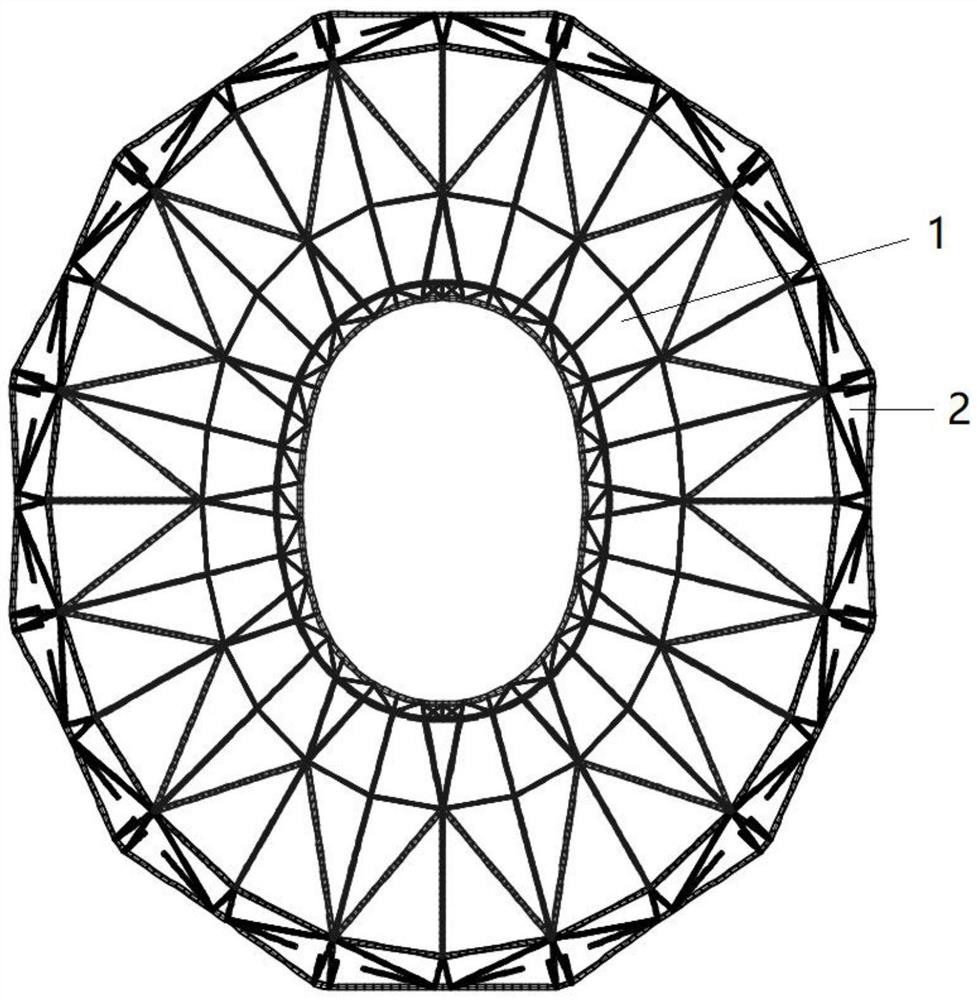

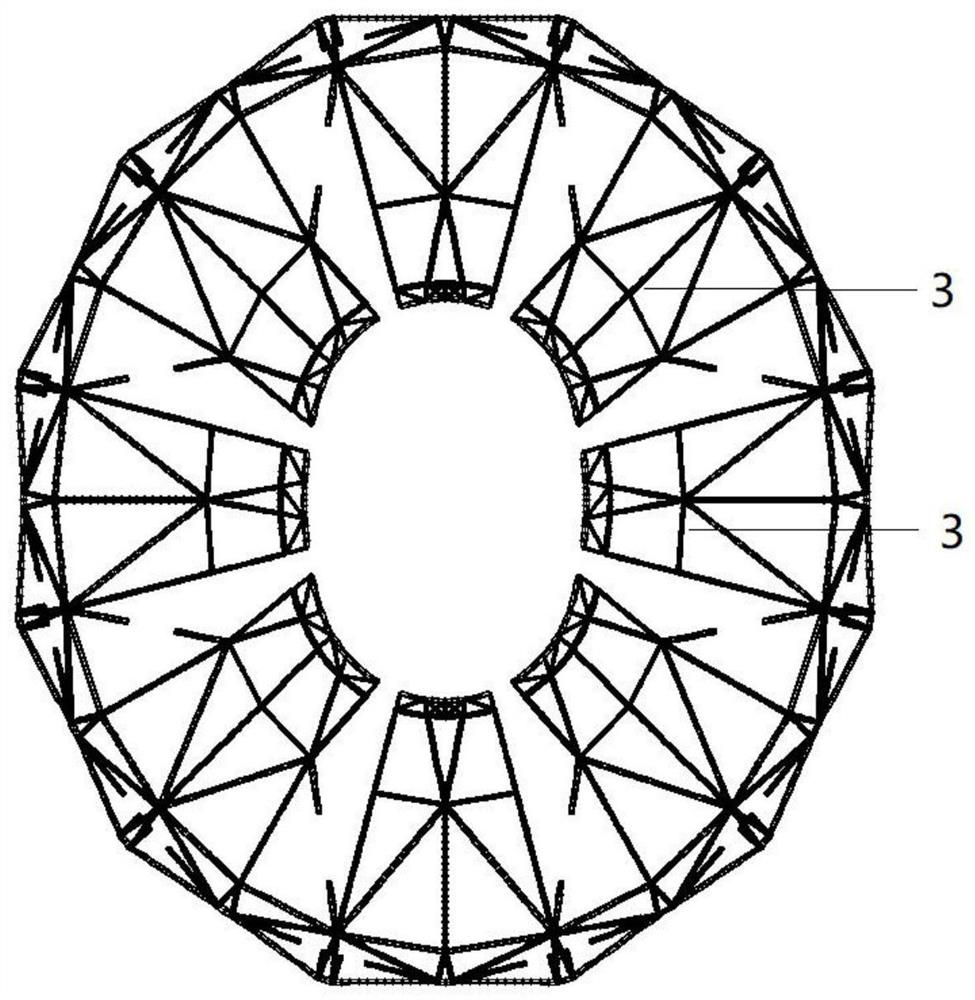

[0043] S1: Figure 1-2 As shown, according to the structural characteristics and functional form of the steel cover, the steel cover is divided into a roofing cover 1 and a facade shed 2; the roofing mask 1 is divided into 8 rotary structural units 3, the divided range of rotation The unit 3 is symmetrically, and ensures that the rotating structure unit 3 is a geometric non-variable system and stabilizes in the plane, and then sequentially numbered the rotating structure unit 3 in the order of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com