Automatic material turning device

An automatic material turning and plate turning technology, which is applied in the field of straw boilers, can solve the problems of long manufacturing and assembly periods, damage to motors and reducers, and high labor costs, and achieve the effects of low production costs, stable operation, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

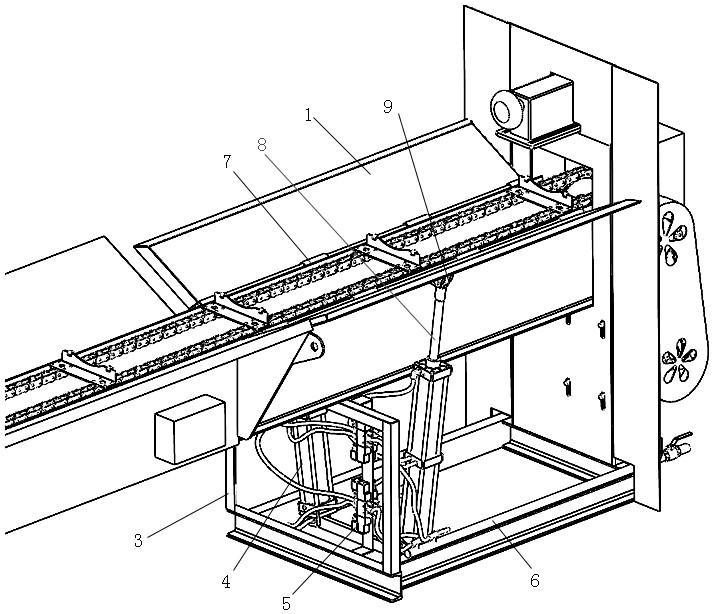

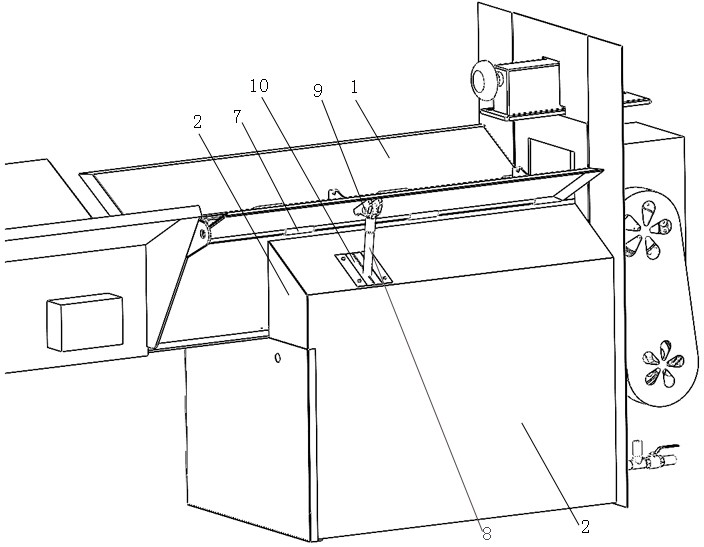

[0021] Such as figure 1 , 2 As shown, the automatic turning device of this embodiment includes a power unit, a turning plate 1, a dust cover 2, a frame 3, a solenoid valve 5, a power source feeding pipe and a PLC control system, and the frame includes a base and a support frame , the base is made of 100° channel steel, the support frame is made of 40° angle steel, and the outside of the frame is provided with a dust cover 2, the dust cover is made of a 1.2mm thick carbon steel plate, and the upper The feeder belt is supported by the frame through the top center of the frame. The power device is a pneumatic device, and the pneumatic device includes two cylinder blocks 4 and a piston rod, and the two cylinder blocks are symmetrically installed on both sides of the conveyor belt of the feeding machine, and there are two flaps, which are symmetrically installed on the top Both sides of the feeder conveyor belt. The cylinder is a double-stroke cylinder, and the double-stroke cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com