Thermal conductive potting composition

A technology of composition and epoxy resin, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that cannot meet the bonding requirements and thermal shock resistance of new energy vehicles at the same time, and cannot meet the thermal management of new energy vehicles Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

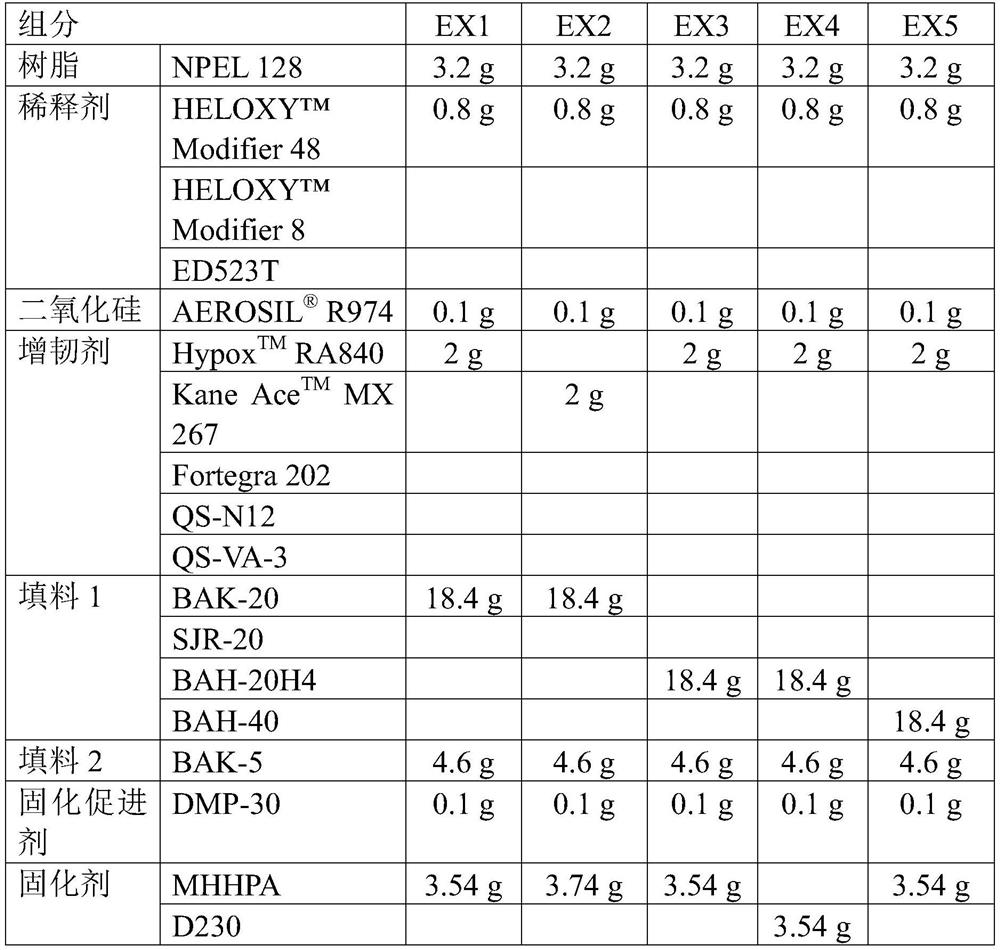

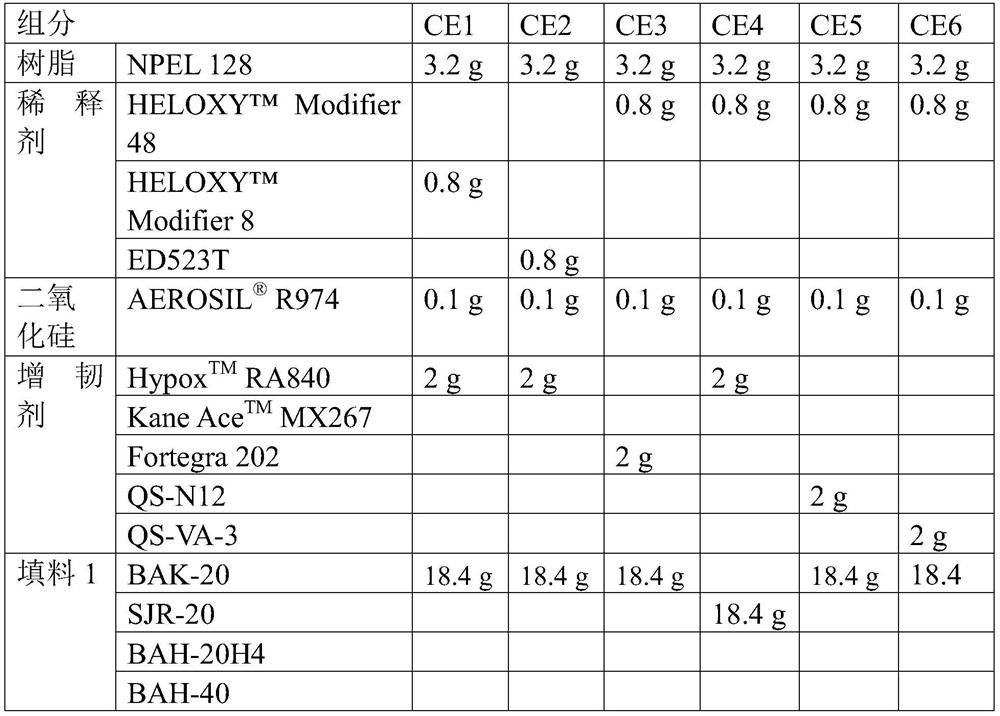

[0134] Example 1 (Ex 1)

[0135] Mix 3.2g of NPEL 128, 0.8g of HELOXY TM Modifier 48 and Hypox 2g TM RA840 was added to Speedmixer DC600 and mixed at 2000rpm for 2 minutes. Then, 4.6g of BAK-5 and 0.1g of R974 was added to the mixer and mixed for 3 minutes at 2000 rpm. Next, 18.4 g of BAK-20 was added to the mixer and mixed at 2000 rpm for 3 minutes. The mixture thus obtained was mixed under vacuum at 2000 rpm for 2 minutes. Then, 0.1 g of DMP 30 and 3.54 g of MHHPA were added to the mixture and mixed. Afterwards, the composition thus obtained is placed in a container for curing.

Embodiment 2

[0136] Example 2 (Ex 2)

[0137] 3.2g of NPEL 128, 0.8g of HELOXY TM Kane Ace with Modifier 48 and 2g TM MX267 was added to Speedmixer DC600 and mixed at 2000rpm for 2 minutes. Then, 4.6g of BAK-5 and 0.1g of R974 was added to the mixer and mixed for 3 minutes at 2000 rpm. Next, 18.4 g of BAK-20 was added to the mixer and mixed at 2000 rpm for 3 minutes. The mixture thus obtained was mixed under vacuum at 2000 rpm for 2 minutes. Then, 0.1 g of DMP 30 and 3.74 g of MHHPA were added to the mixture and mixed. Afterwards, the composition thus obtained is placed in a container for curing.

Embodiment 3

[0138] Example 3 (Ex 3)

[0139] Mix 3.2g of NPEL 128, 0.8g of HELOXY TM Modifier 48 and Hypox 2g TM RA840 was added to Speedmixer DC600 and mixed at 2000rpm for 2 minutes. Then, 4.6g of BAK-5 and 0.1g of R974 was added to the mixer and mixed for 3 minutes at 2000 rpm. Next, 18.4 g of BAH-20H4 was added to the mixer and mixed at 2000 rpm for 3 minutes. The mixture thus obtained was mixed under vacuum at 2000 rpm for 2 minutes. Then, 0.1 g of DMP 30 and 3.54 g of MHHPA were added to the mixture and mixed. Afterwards, the composition thus obtained is placed in a container for curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com