Pultrusion composite material floor for breeding as well as preparation method and mounting structure of pultrusion composite material floor

A composite material board and composite material technology are applied in the field of pultruded composite material floor for aquaculture, a preparation method and an installation structure thereof, which can solve the problems of high replacement panel cost, low installation efficiency, and inability to replace, so as to meet the bearing requirements, Simple installation structure, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] On the other hand, the embodiment of the present invention also discloses a method for preparing a pultruded composite floor for farming, which is used to prepare the pultruded composite floor for farming disclosed in any of the above embodiments, which specifically includes the following steps:

[0087] Step 1: The prepared composite material raw material is heated and formed through the mold, and the pultrusion equipment pulls it from the mold to the cutting equipment, and cuts it into a pultruded composite material plate of a specified length through the cutting equipment;

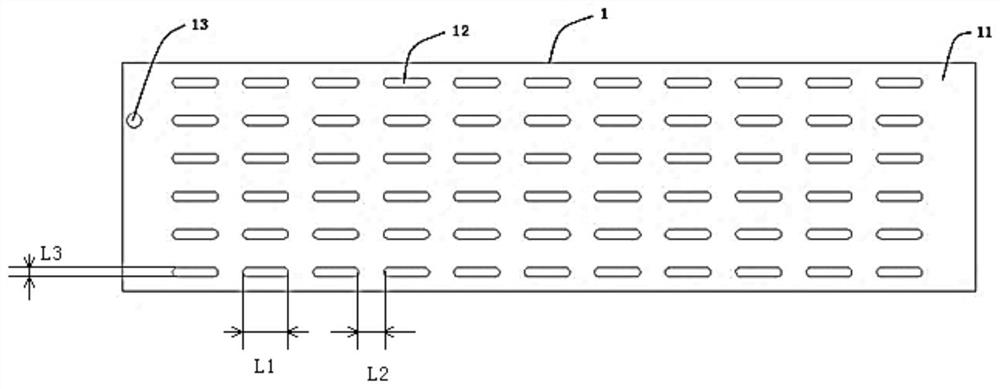

[0088] Step 2: Punch holes on the pultruded composite board body obtained in Step 1 according to the specified interval through the punching equipment, so as to facilitate the drainage of rainwater or excrement;

[0089] Step 3: Roll a layer of adhesive on the surface of the pultruded composite board body obtained in Step 2, spread a wear-resistant sand layer, and after drying, perform two-layer g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com