Steamed bun steaming system and steaming method

A steamed bun and steaming technology, which is applied to a steamed bun steaming system and its steaming field, can solve the problems of poor steaming effect, waste of resources, deformation of trays, etc., so as to improve the utilization rate of resources, ensure the steaming effect, and prevent deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

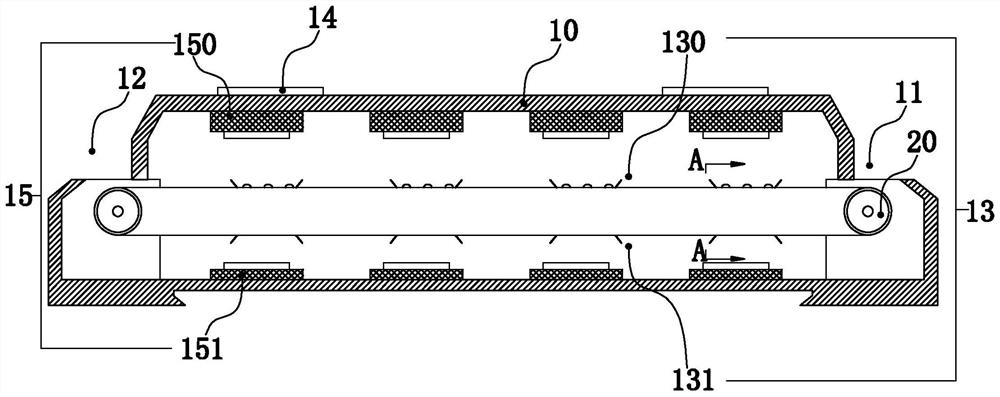

[0049] Such as Figure 1-Figure 4 As shown, the present invention discloses a system for steaming steamed buns, which includes an oven body 10, a baking channel 13 provided in the oven body 10 and having a discharge port 11 and a discharge port 12, and a baking channel 13 provided in the oven body 10. The humidity adjustment door 14 on the top, the heating module 15 provided in the baking channel 13 and the conveying device 20 provided in the baking channel 13 and used to transport the baked goods. In a specific embodiment of the present invention, the conveying The device 20 divides the baking tunnel 13 into a baking zone 130 and a preheating zone 131;

[0050] The heating module 15 includes a plurality of heating parts 150 arranged in the baking area 130 and arranged at intervals in the conveying direction of the conveying device 20 to heat the baked goods, and a plurality of heating parts 150 arranged in the preheating area 131 and The preheating section 151 arranged at in...

Embodiment 2

[0060] Embodiment 2, the difference with embodiment 1 is that

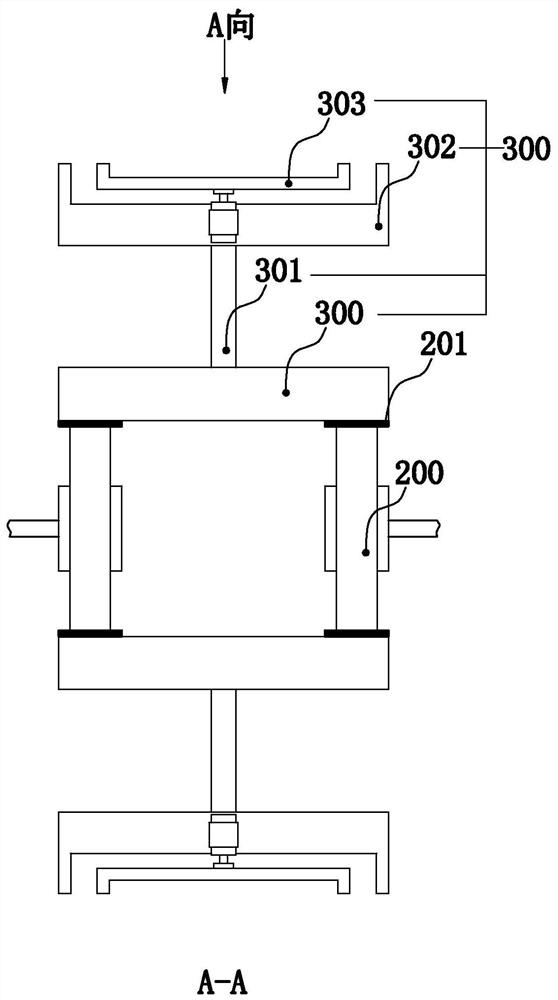

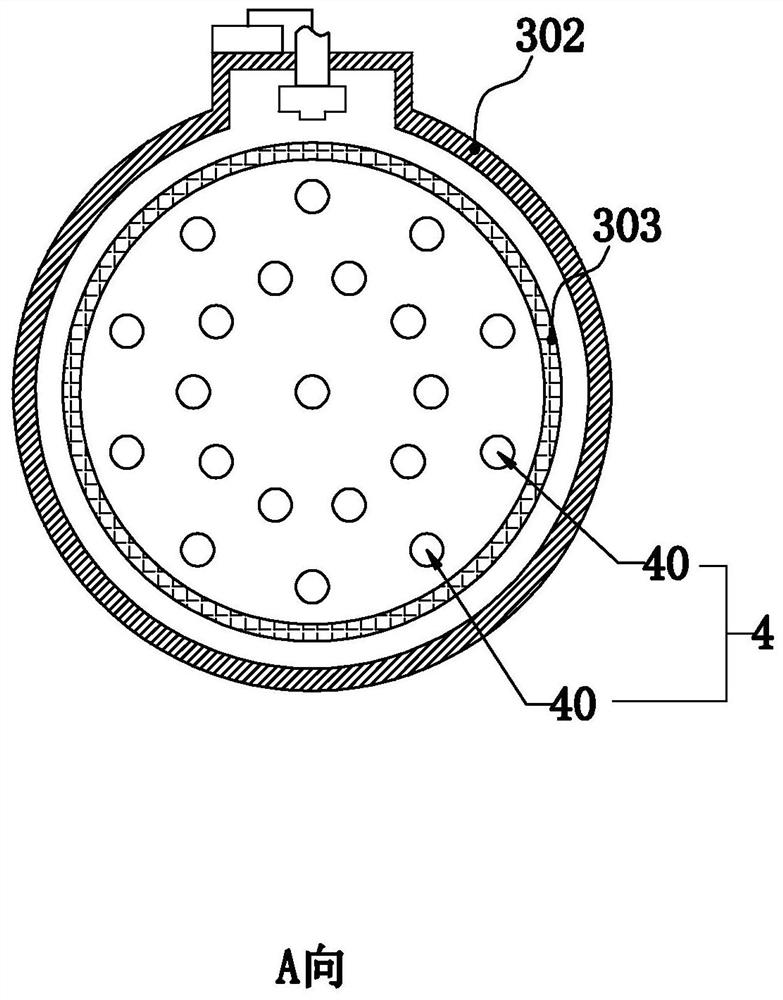

[0061] Such as Figure 5-Figure 7 As shown, in the specific embodiment of the present invention, the base plate 300 is also provided with a first air supply part 50; the first air supply part 50 includes at least three The center of the substrate 300 is equidistantly spaced around the center and is driven by a transmission wheel 501 driven by a plc motor 500, a transmission belt 502 connected to the transmission wheel 501, and several fixedly connected transmission belts 502 located adjacent to the transmission wheel 501. The first air pipe 503 extending radially between them and several slide rails 504 installed on the base plate 300 and between the adjacent transmission wheels 501, the first air pipe 503 is provided with several air holes 505 and is connected with The sliding rail 504 is slidably connected, and a first air source 506 is installed on the base plate 300 for supplying air to the first air pipe 503...

Embodiment 3

[0081] Embodiment 3, the difference with embodiment 2 is that

[0082] Such as Figure 8-Figure 12 As shown, in the specific embodiment of the present invention, the second split body 3022 on each tray device 30 is provided with an exhaust port 3022a, and the substrate 300 of the adjacent tray device 30 passes through the frame body 70 and the conveyor belt 201 connected, the substrate 300 on each tray device 30 is slidingly connected to the inner wall of the frame body 70, and is arranged symmetrically with the center of the frame body 70 so that the adjacent tray devices 30 form an integrated mutual heating system 30a; wherein, the frame body 70 includes a rectangular frame body 700, an active area 701 provided inside the frame body 700 for the substrate 300 to move, a first sliding port 702 and a second sliding port 702 arranged longitudinally on the same outer wall of the frame body 700 The second sliding port 703, the first rack 705 matched with the first sliding port 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com