Apple peeling equipment used for canned food processing

A technology for canned food and apples, applied in the field of apple peeling equipment for canned food processing, can solve the problems of wasting pulp, difficult to control the peeling depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

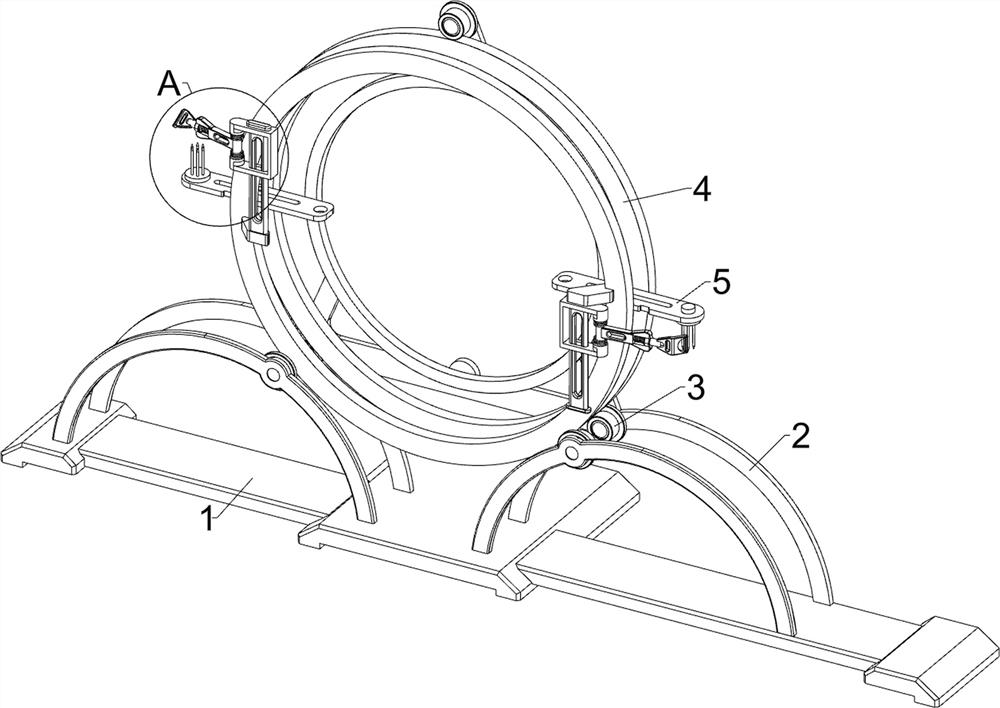

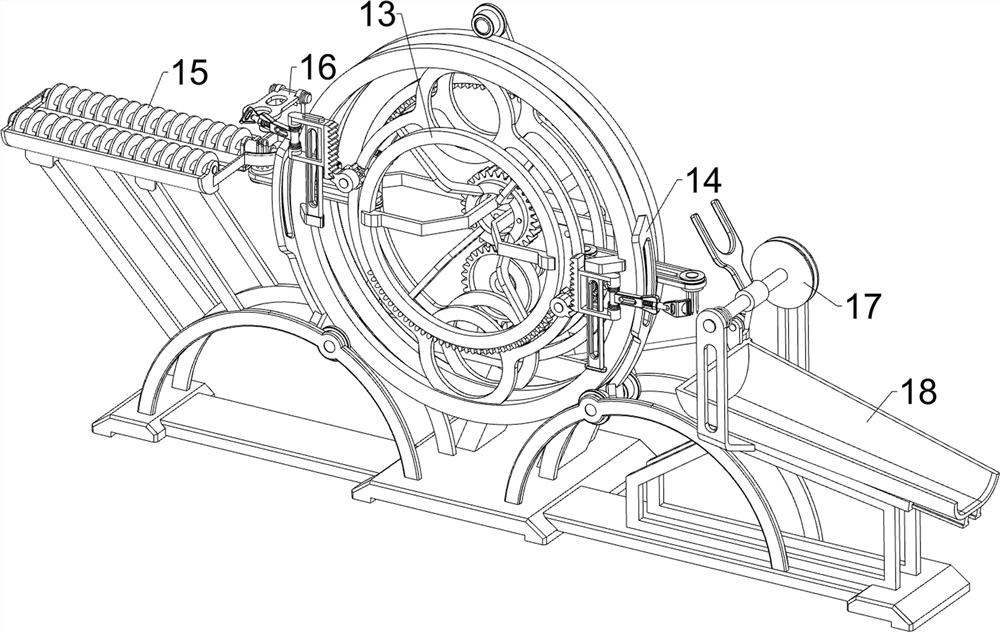

[0027] A kind of apple peeling equipment for canned food processing, refer to figure 1 , figure 2 and image 3 As shown, it includes a base plate 1, a first support frame 2, a limit wheel 3, a first mounting ring 4, a second mounting plate 5, a first slide rail 6, a third mounting block 7, a fourth mounting block 8, a A torsion spring 9, a cutter head 10, a second torsion spring 11, a steel needle socket 12, a rotating mechanism 13 and a moving mechanism 14, the top of the base plate 1 is provided with a first support frame 2, and the first support frame 2 is provided with five limiters. The position wheel 3 and the limit wheel 3 are divided into the front two and the rear three. The limit wheels 3 on the front and rear sides are connected with the first installation ring 4 in a rotational manner, and the first installation ring 4 is symmetrically connected with the second installation ring. plate 5, the second mounting plate 5 is equipped with a steel needle socket 12 in a...

Embodiment 2

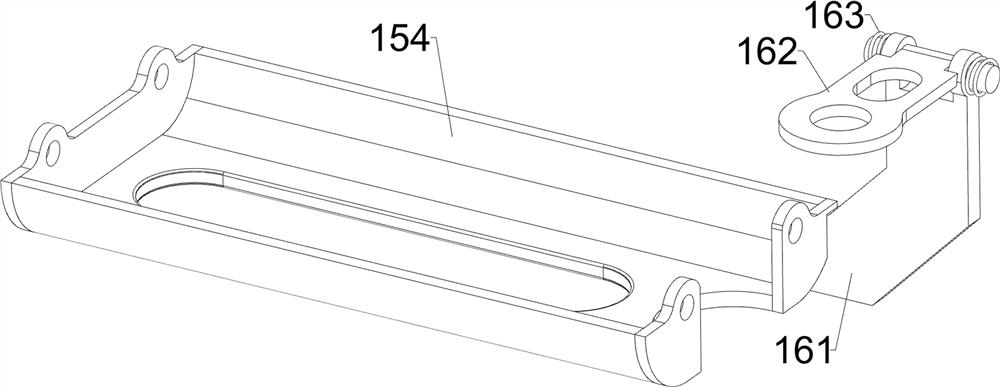

[0032] On the basis of embodiment 1, refer to Figure 7 and Figure 8 As shown, also includes feeding mechanism 15, and feeding mechanism 15 includes toothed ring 151, the 3rd gear 152, worm screw 153, mounting groove 154, the second belt 155, the first baffle plate 156, the 3rd supporting frame 157 and Limiting plate 158, gear ring 151 is arranged on the first installation ring 4 on the rear side, a plurality of third support frames 157 are uniformly arranged on the left side of the first support frame 2, and installation grooves 154 are connected between the tops of the third support frames 157 On the installation groove 154, a worm screw 153 is arranged in a forward and backward symmetrical rotation type, and a third gear 152 is arranged on the right side of the rear side worm screw 153, and the third gear 152 meshes with the ring gear 151, and a second belt 155 is connected between the left side of the worm screw 153, The middle part of the installation slot 154 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com