A kind of preparation method of gamma-feooh catalyst

A technology of catalyst and iron shavings, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of uneven adhesion of γ-FeOOH, etc., and achieve the effect of high adhesion strength and enhanced removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment prepares iron-based catalysts under laboratory conditions according to the preparation method of the present invention, and the specific steps are as follows:

[0037] (1) Washing of iron shavings: immerse 200g of iron shavings in a sodium hydroxide solution with a concentration of 0.01M for 40 minutes to remove the oil remaining on the surface, then remove and rinse, and then immerse in a sulfuric acid solution with a concentration of 0.01M Etching for 40 minutes to make the surface rough and easy to modify, wash and set aside after etching;

[0038] (2) Immerse the iron shavings treated in step (1) in a mixed solution of 2L of sodium sulfate and ammonium sulfate for 5 minutes, the concentration of sodium sulfate is 0.05M, and the concentration of ammonium sulfate is 0.05M, and the iron shavings are taken out and air-dried for 10 minutes after centrifugal dehydration , repeat the operation for 60 minutes alternately between dry and wet, so that t...

Embodiment 2

[0042] (1) the washing of iron shavings is with embodiment 1;

[0043] (2) Immerse 200g of iron shavings treated according to 1) in a mixed solution of 2L of sodium sulfate (0.05M) and ammonium sulfate (0.05M) for 5 minutes, remove and centrifugal dehydrate, air-dry for 10 minutes, and then repeat the immersion operation for 5 minutes. Repeat the operation for 50 minutes so that the surface is covered with a large area of green embroidery;

[0044] (3) Weigh 200g of the obtained iron shavings covered with green embroidery and immerse them in the solution of (2), then continuously expose oxygen into the solution for 60 minutes using a micro-nano bubble generator; finally remove the iron shavings, rinse them, dry them, Finally, the surface-loaded γ-FeOOH catalyst with iron shavings as the carrier was obtained. The time of using pure oxygen aeration can be slightly less than the air aeration time adopted in Example 2.

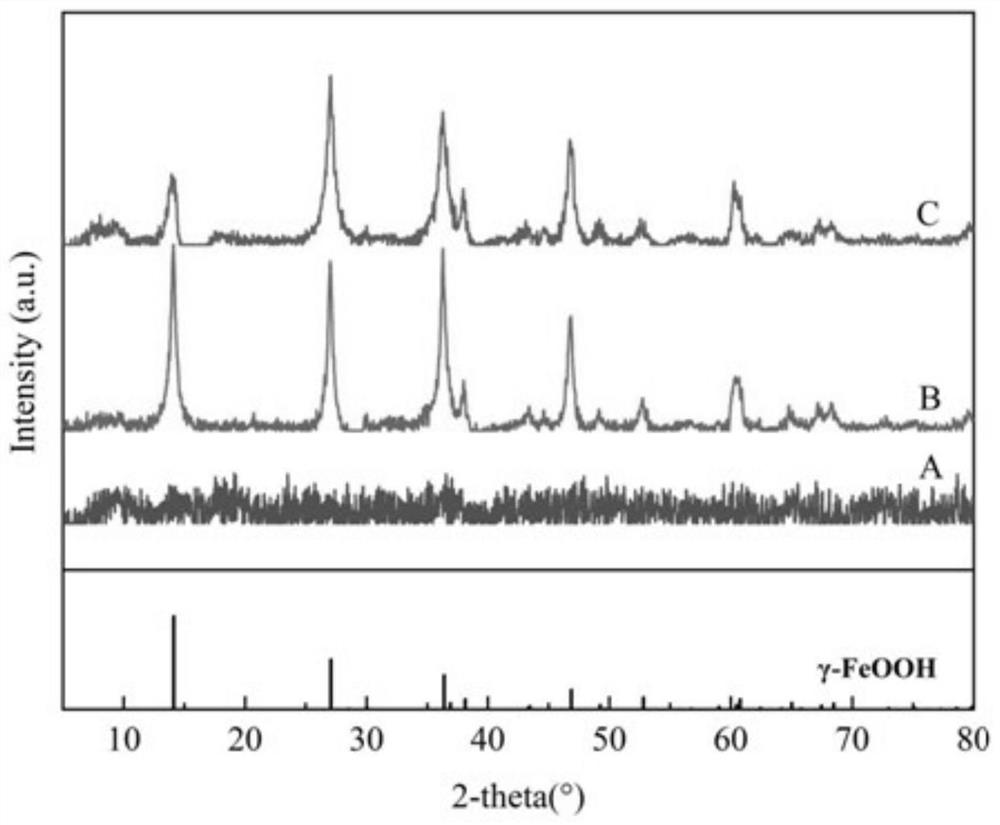

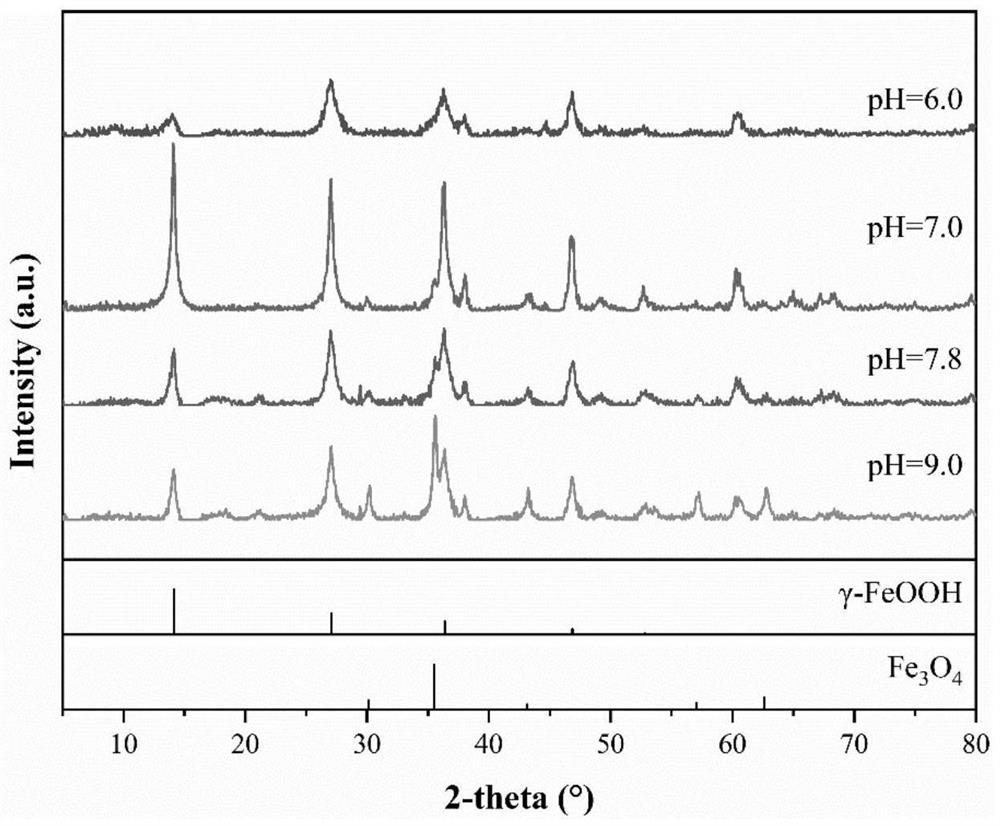

[0045] Such as figure 1 as shown in figure 1 The XRD a...

Embodiment 3

[0047] In this embodiment, the conditions for uniform generation of surface green rust of iron shavings by alternating drying and wetting are specifically described.

[0048] 1) the washing of iron shavings is with embodiment 1;

[0049] The first group immerses 200g of iron shavings treated according to step (1) in 2L of a mixed solution of sodium sulfate and ammonium sulfate for 5 minutes, wherein the concentration of sodium sulfate is 0.05M, and the concentration of ammonium sulfate is 0.05M, and the iron shavings are taken out and air-dried after centrifugal dehydration 10 minutes, then repeat the immersion operation for 5 minutes, and repeat the operation for 50 minutes so that the surface is covered with a large area of green embroidery; during the experiment, observe the formation of green rust on the surface of the iron shavings;

[0050] In the second group, 200 g of iron shavings treated according to step (1) were immersed in 2L of a mixed solution of sodium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com