A gear processing surface grinding device

A surface processing and smoothing technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, metal processing equipment, etc., can solve the problems of simple structure, inconvenient use, cumbersome process of fixing and dismounting, etc., so as to improve the convenience performance, the effect of improving the speed of reclaiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

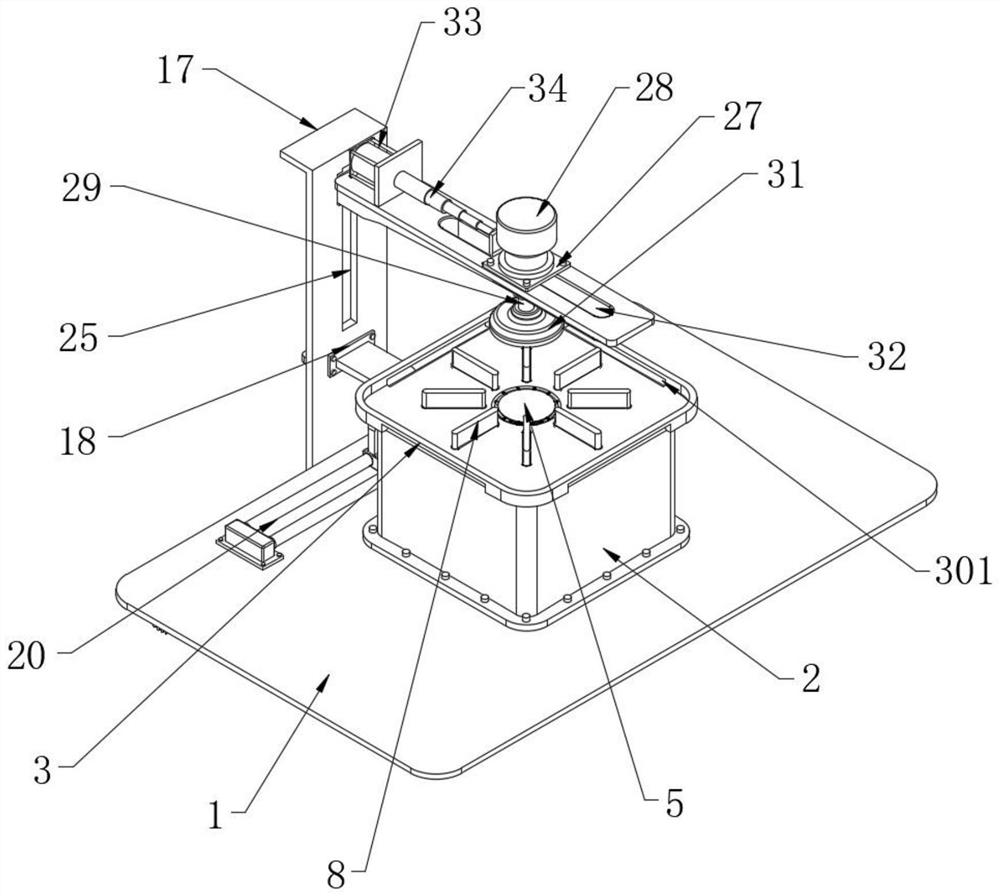

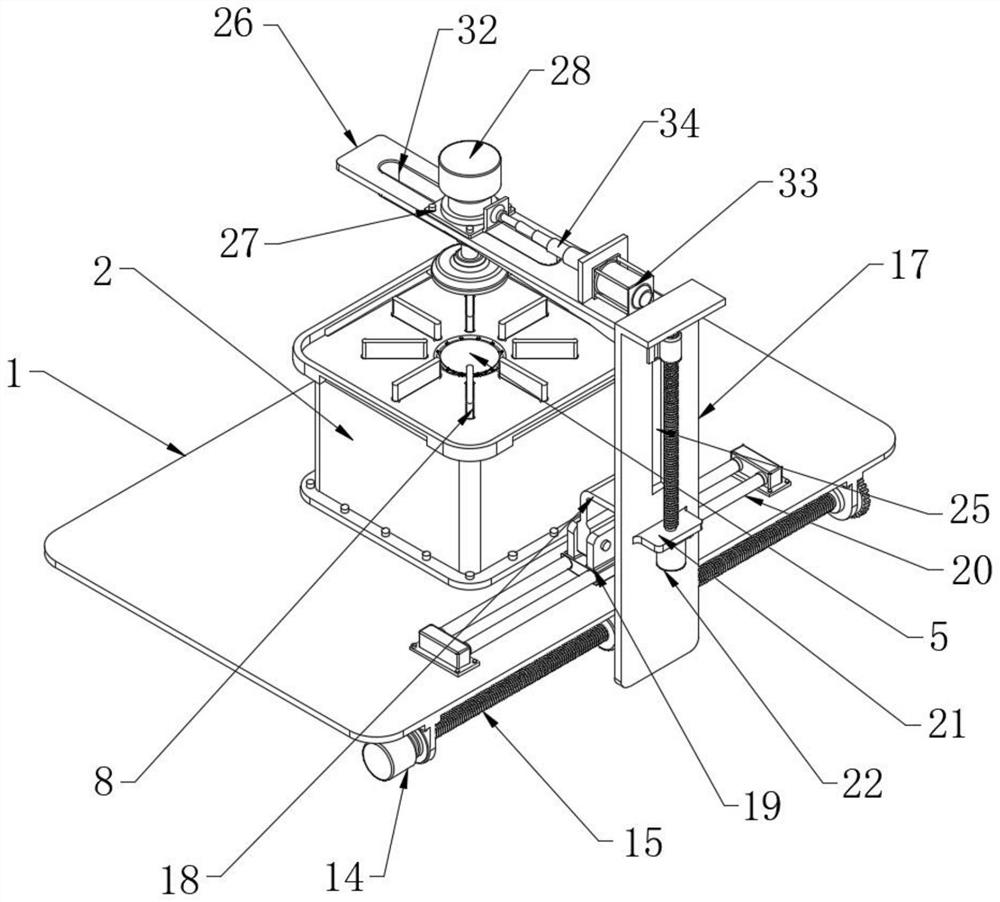

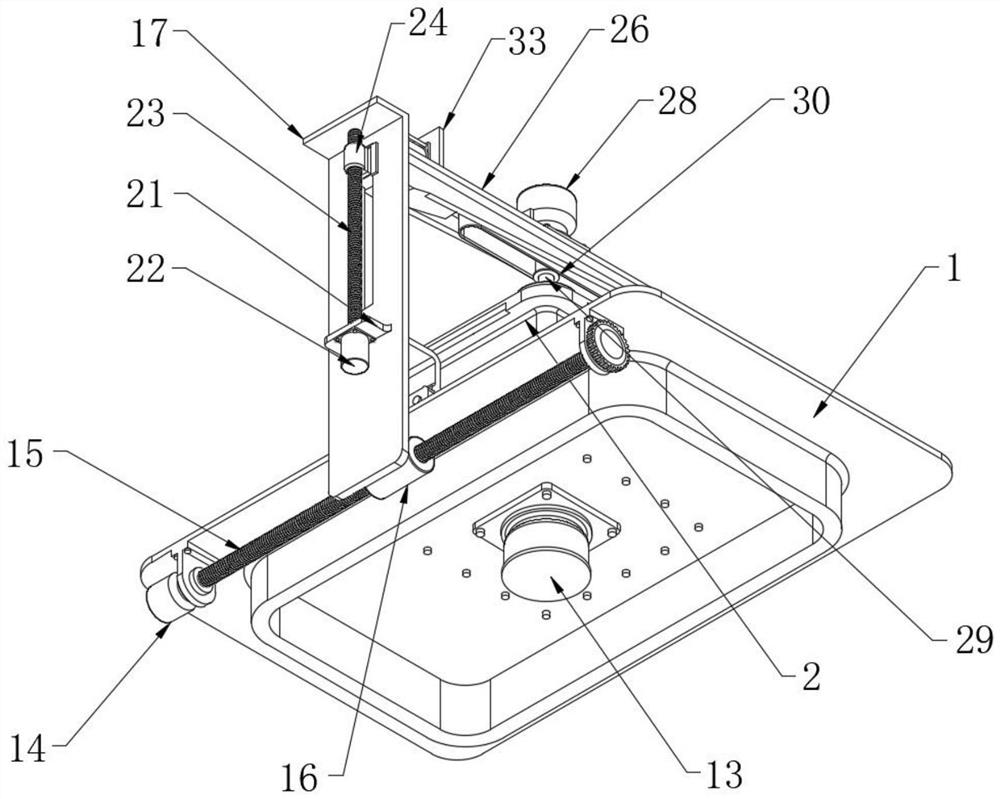

[0033] Please refer to Figure 1 to Figure 11Shown, it has shown the concrete structure of the preferred embodiment of the present invention, a kind of gear processing surface grinding device, comprises bottom plate 1 and top cover 5, and the top of described bottom plate 1 is equipped with top shell 2, and top shell 2 and the center line of the bottom plate 1 are on the same vertical line; the top of the top shell 2 is provided with a processing groove 3, and the inner center of the processing groove 3 is provided with a top groove 4; the top cover 5 is set Inside the top groove 4, and the bottom of the top cover 5 is equipped with a push rod 6, and the center line of the push rod 6, the center line of the top groove 4 and the center line of the top cover 5 are all on the same vertical straight line; the top cover 5 includes a first fixed ring 501 and a second fixed ring 505, the first fixed ring 501 is arranged on the upper part of the second fixed ring 505, and the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com