Prefabricated component lightweight steel mold table of integrated maintenance system and using method of prefabricated component lightweight steel mold table

A technology of prefabricated components and maintenance system, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of vacancy of mold table equipment, high input cost, difficult transportation, etc., to shorten the production line takt, enhance the maintenance effect, and avoid pollution. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

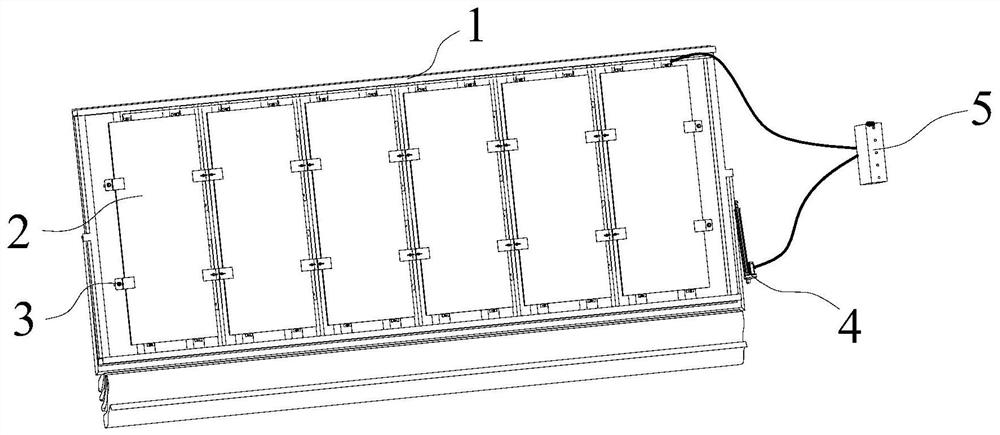

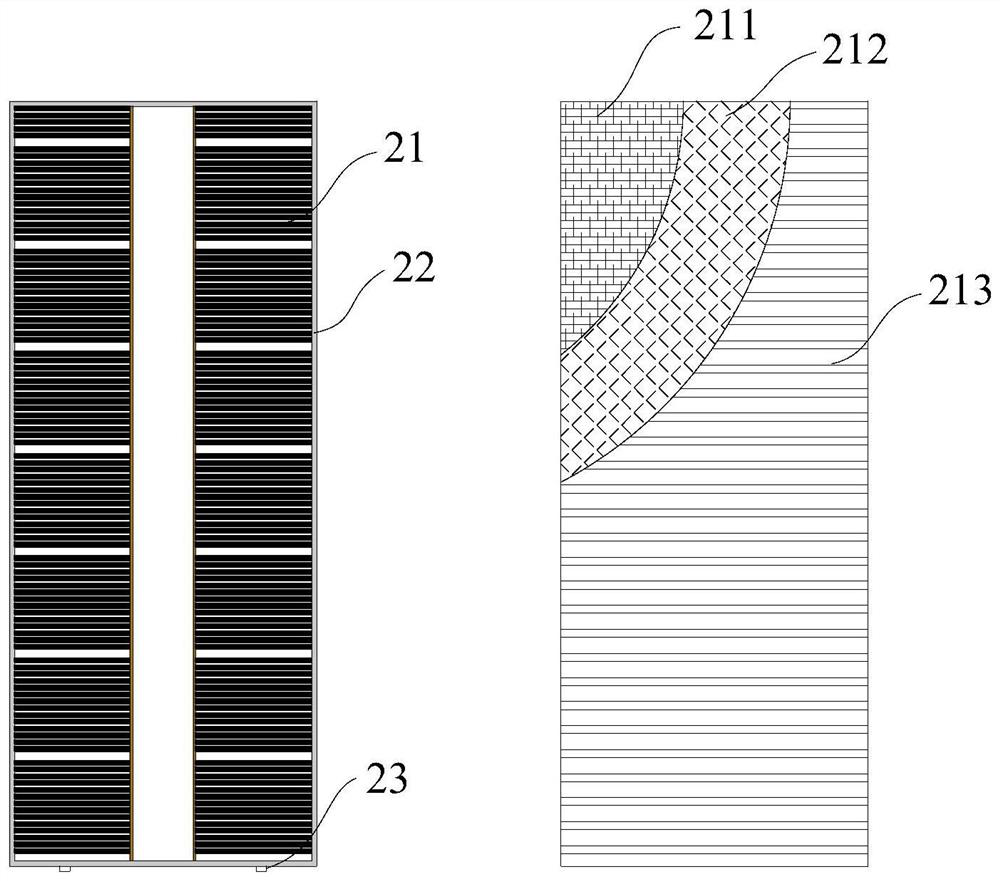

[0035] Such as Figure 1-6 As shown, this embodiment introduces a prefabricated component lightweight steel formwork platform with an integrated maintenance system, including a lightweight formwork platform 1, and an electric heating maintenance module 2 installed under the lightweight formwork platform, which is used to convert the electric heating maintenance module 2 An integrated isolation component 3 fixed under the lightweight mold table 1 and forming an air chamber, an automatic cloth covering mechanism 4 for enhancing the maintenance effect, and an electrical control cabinet 5 for realizing electrical control.

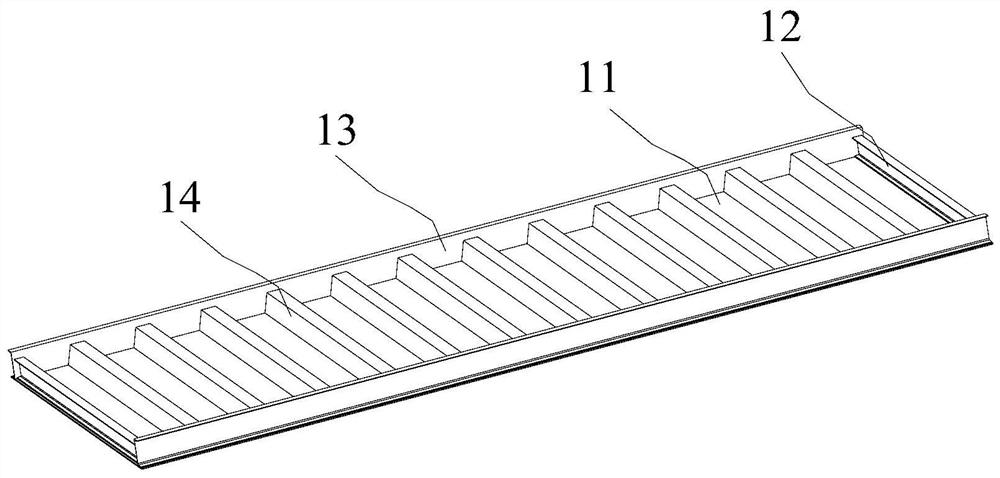

[0036] The lightweight mold table 1 includes a panel 11 , an end support 12 , an edge support 13 , and a bottom ladder support 14 . The lightweight mold table 1 is a common mold table with a width of 3.5 meters and a length of 9 meters. For the convenience of production and processing, the end supports 12 and the side supports 13 are standard profiles, and the ...

Embodiment 2

[0041] Such as Image 6 As shown, this embodiment provides a method for using a lightweight steel formwork platform for prefabricated components integrated with the maintenance system. Including the following steps:

[0042] Step 1, the electric heating maintenance module 2 is integrated with the lightweight mold table 1 through the integrated isolation component 3, the automatic cloth covering mechanism 5 is integrated into the lightweight mold table 1, and the wiring of each electrical control part and the electrical control cabinet 5 is completed.

[0043] Step 2, transport the processed prefabricated component steel formwork table with maintenance system to the fixed formwork production line or the nomadic production line for installation and fixation, and electrify the electrical control cabinet 5 .

[0044] Step 3: Complete the series of prefabricated component production operations on the panel 11 such as cleaning the formwork, assembling the mold, binding steel bars, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com