Rotary kiln method for recycling red mud technology and rotary kiln

A rotary kiln and resource-based technology, which is applied in waste heat treatment, chemical industry, process efficiency improvement, etc., can solve the problems of pollution hazards, high cost, and high energy consumption of the treatment method, so as to avoid the risk of explosion and reduce the treatment cost. cost and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

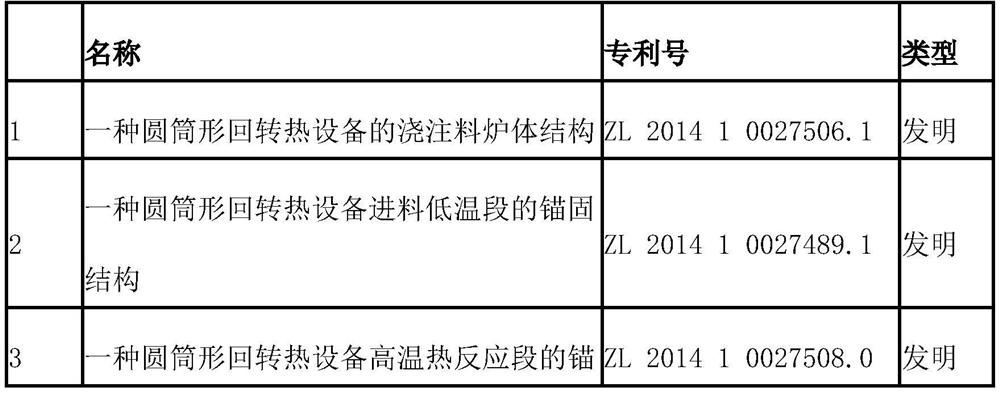

- Application Information

AI Technical Summary

Problems solved by technology

Method used

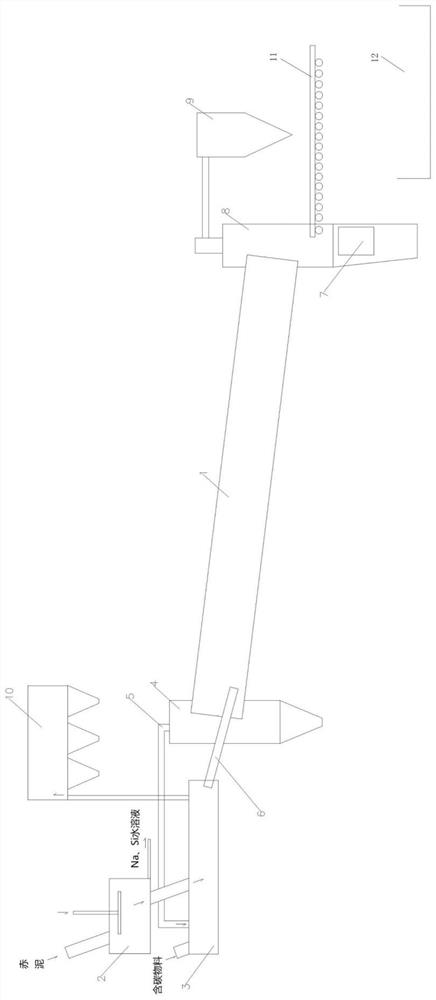

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content, achieved objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments.

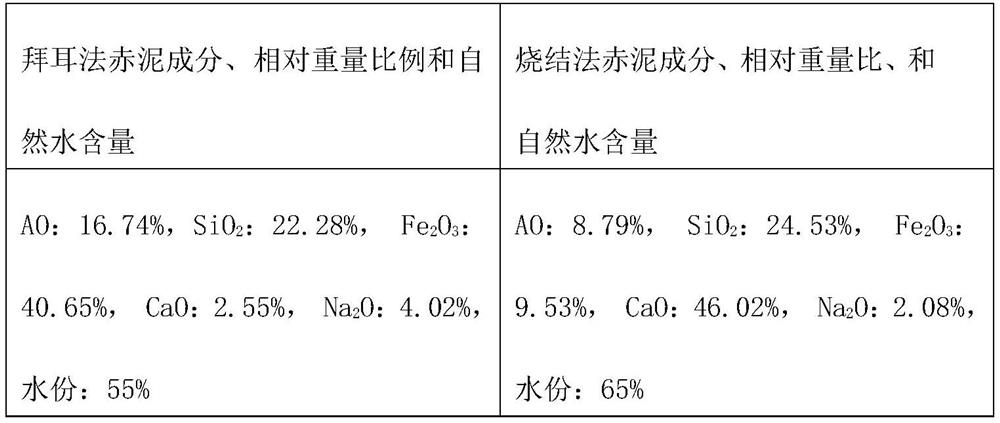

[0039] This embodiment provides a process for recycling red mud by the rotary kiln method. The red mud containing sodium ferrite water glass alkali solution is mixed with carbon-containing materials and mixed with each other. For example, 100 tons of red mud mixed materials are put in at a time. Among them, the carbon-containing material accounts for 50-55% by weight, and the red mud accounts for 45% by weight. A rotary kiln is used as the main equipment for process treatment, and the mixed material is added to the rotary kiln. Through the smelting reaction in the rotary kiln, Different from the conventional smelting process, the red mud is separated and decomposed, and iron, ferrosilicon, high-temperature silica clinker, industrial glass, and sodium salt ultrafine powder and vapor-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com