Circuit structure for measuring and burning PCB fuse

A circuit structure and fuse technology, applied in the information field, can solve problems such as difficult tracking and waste of manpower, and achieve the effect of liberating manpower, simple structure and reliable design principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

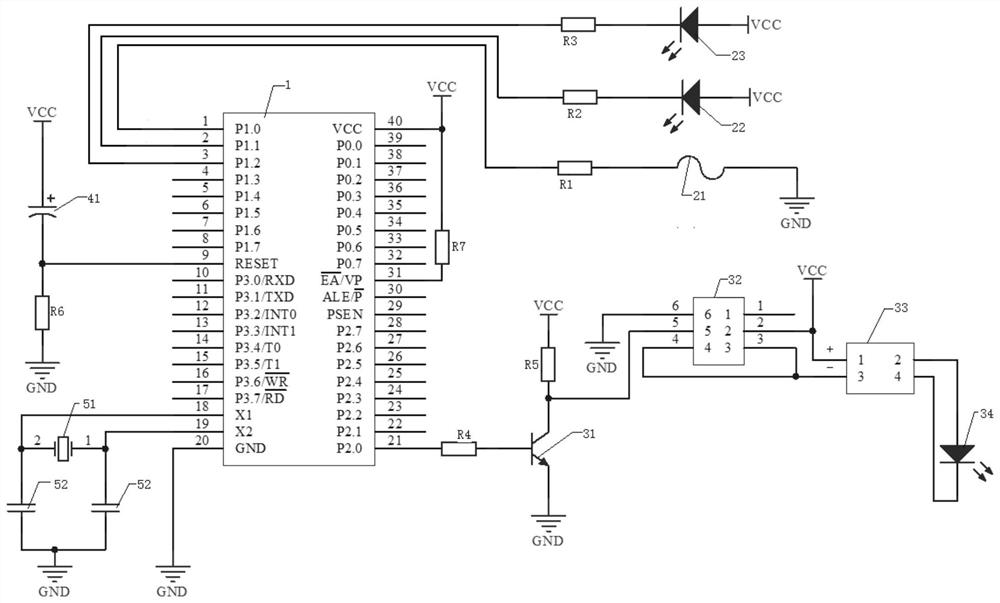

[0030] Such as figure 1 As shown, a circuit structure for PCB fuse measurement and programming includes a control chip 1, a reset circuit, a crystal oscillator circuit, a fuse measurement circuit, and a BIOS programming circuit.

[0031] The reset circuit includes an electrolytic capacitor 41 and a resistor R6, the positive pole of the electrolytic capacitor 41 is connected to the fifth power supply, the negative pole of the electrolytic capacitor 41 is connected to the first end of the resistor R6, and the first end of the resistor R6 is connected to the reset pin of the control chip 1 connected, the second end of the resistor R6 is grounded; the reset circuit is connected to the reset pin of the control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com