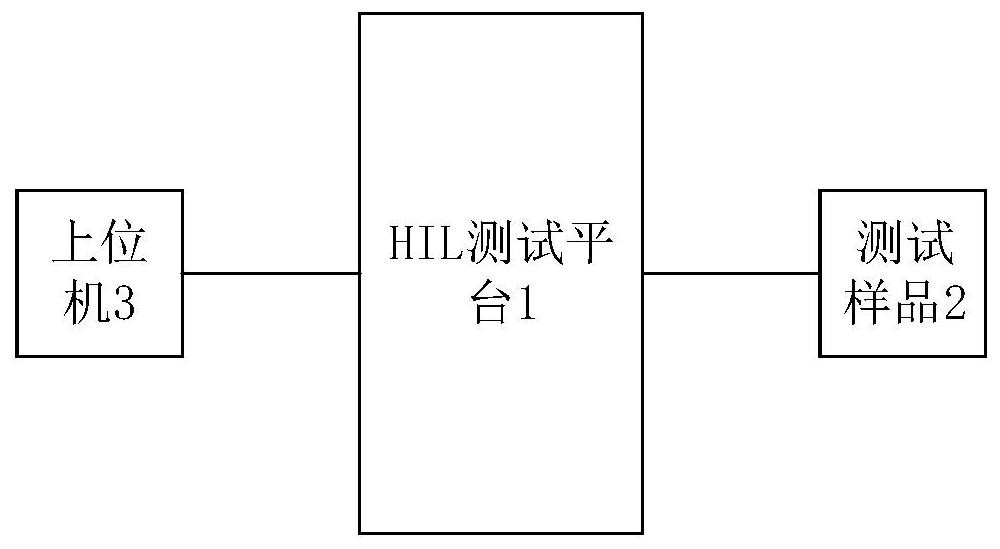

Hardware-in-loop closed-loop test method and system for battery management system

A technology of battery management system and test method, which is applied in the direction of electrical test/monitoring, general control system, control/regulation system, etc. It can solve the problems of low closed-loop test coverage and insufficient closed-loop degree, so as to improve product design and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 comprises the following steps:

[0055] S1, connect the BMU slave control unit and the HIL test platform 1;

[0056] S2. Use dSPACE's ConfigurationDesk to configure the real-time external hardware interface, which is used to manage the signal path between the BMU slave control unit and the model; set the I / O and monitoring, and the model of the controlled object based on dSPACE;

[0057]S3. Generate codes for the I / O, monitoring, and controlled object models set in step S3, and download them to the HIL test platform 1 through dSPACE's ControlDesk for signal interaction testing, and record experimental data.

[0058] The model includes: a battery model, including parameter information such as the voltage, temperature, and balanced current of a single or module battery. The battery model adopts a second-order circuit model, and the model is integrated in the HIL test platform 1;

[0059] The interface model between the BMU slave control unit and the SCU: CAN...

Embodiment 2

[0062] Embodiment 2 comprises the following steps:

[0063] S1, connecting the SCU host control unit and the HIL test platform 1;

[0064] S2. Use dSPACE's ConfigurationDesk to configure the real-time external hardware interface, which is used to manage the signal path between the SCU host control unit and the model; set the I / O and monitoring, and the model of the controlled object based on dSPACE;

[0065] S3. Generate codes for the I / O, monitoring, and controlled object models set in step S3, and download them to the HIL test platform 1 through dSPACE's ControlDesk for signal interaction testing, and record experimental data.

[0066] The models include:

[0067] SCU host control unit and high voltage relay, loop interlock I / O interface model, said model is integrated in HIL test platform 1;

[0068] The communication interface model between the SCU host control unit and n BMUs: CAN communication establishes a communication model by importing DBC files; the daisy chain is...

Embodiment 3

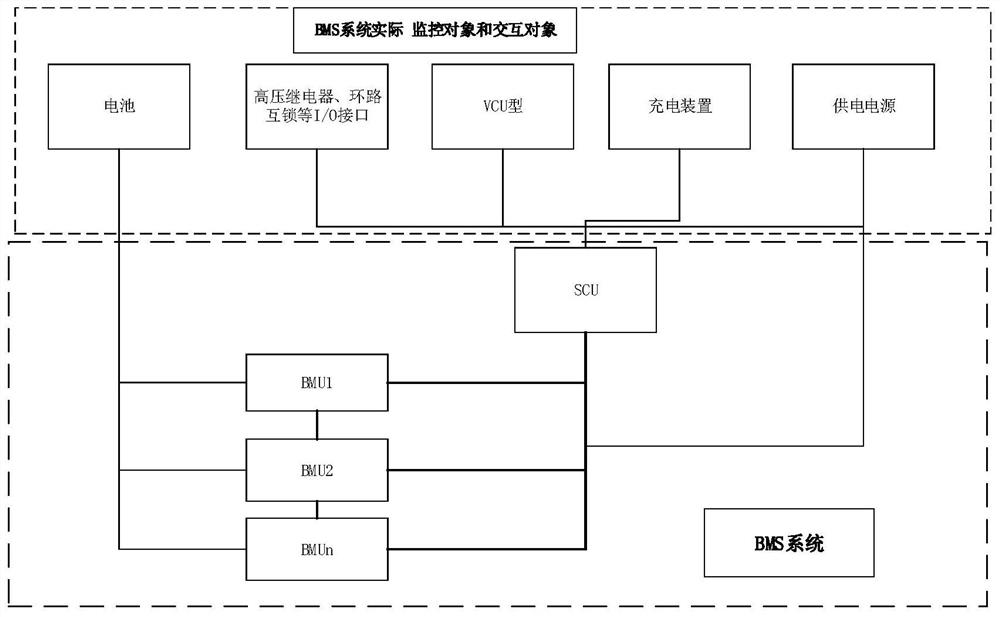

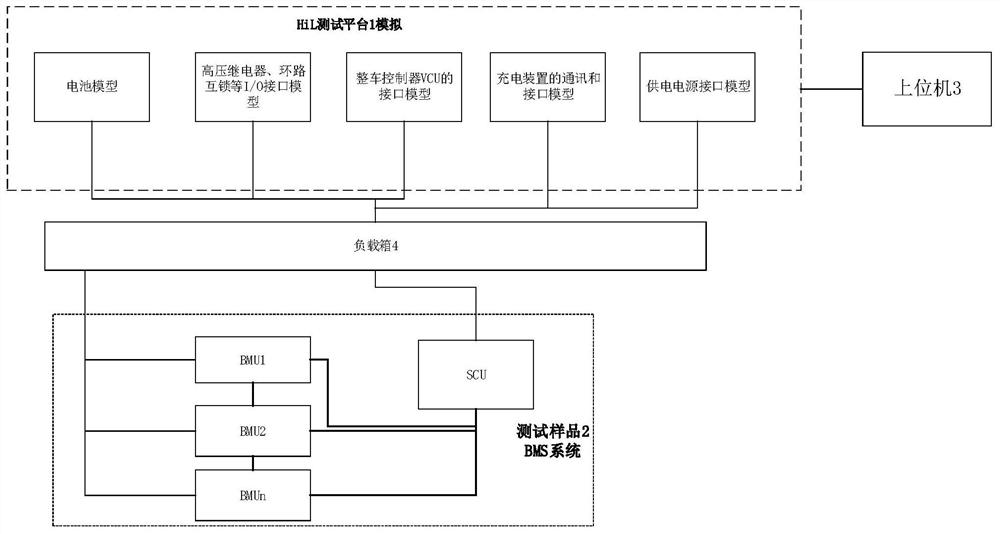

[0073] Embodiment 3 comprises the following steps:

[0074] S1, connect the BMS system and the HIL test platform 1;

[0075] S2. Use dSPACE's ConfigurationDesk to configure the real-time external hardware interface to manage the signal path between the BMS system and the model; set the I / O and monitoring, and the model of the controlled object based on dSPACE;

[0076] S3. Generate codes for the I / O, monitoring, and controlled object models set in step S3, and download them to the HIL test platform 1 through dSPACE's ControlDesk for signal interaction testing, and record experimental data.

[0077] The models include:

[0078] The battery model includes parameter information such as the voltage, temperature, and balanced current of a single or module battery. The battery model adopts a second-order circuit model, and the model is integrated in the HIL test platform 1;

[0079] The model includes: a battery model, including parameter information such as the voltage, temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com