Device and method for rapidly detecting defects of wide glass

A technology for glass defects and detection methods, applied in image data processing, instrument, character and pattern recognition, etc., can solve the problems of easy detection by external interference, low detection efficiency, and large detection time consumption, so as to solve the problem of rapid detection, High degree of automation and the effect of ensuring full coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

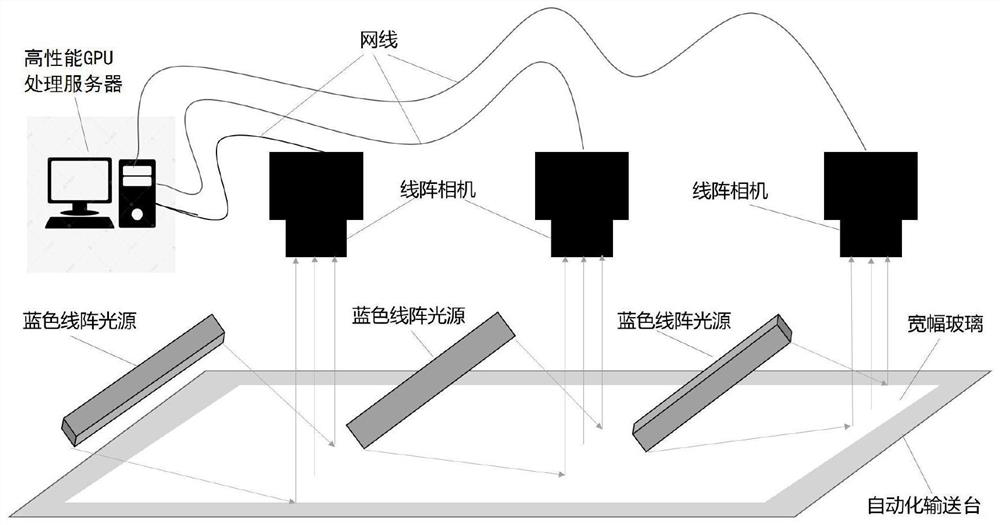

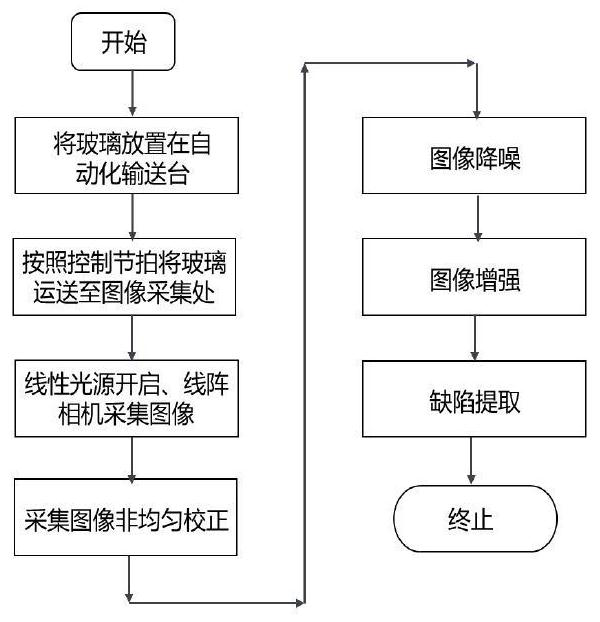

[0020] according to figure 1 , 2 As shown, this embodiment provides a wide-width glass defect rapid detection device and method, including an automatic conveying platform, a line array camera, a blue linear parallel light source and a high-performance GPU processing server, and the automatic conveying platform is used to prevent conveying The detected wide-width glass is controlled by PLC, and moves at a certain control beat speed according to the test requirements. The line array camera is used to collect images of the detected wide-width glass, and the blue linear parallel light source is used to assist the line array The camera fills in light to collect images, and the high-perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com