Synchronous motor slip ring surface online repairing device and repairing method

A technology of synchronous motor and repair method, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of long time-consuming repair of the slip ring surface of synchronous motors, and achieve the goals of improving repair efficiency, slowing down vibration, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

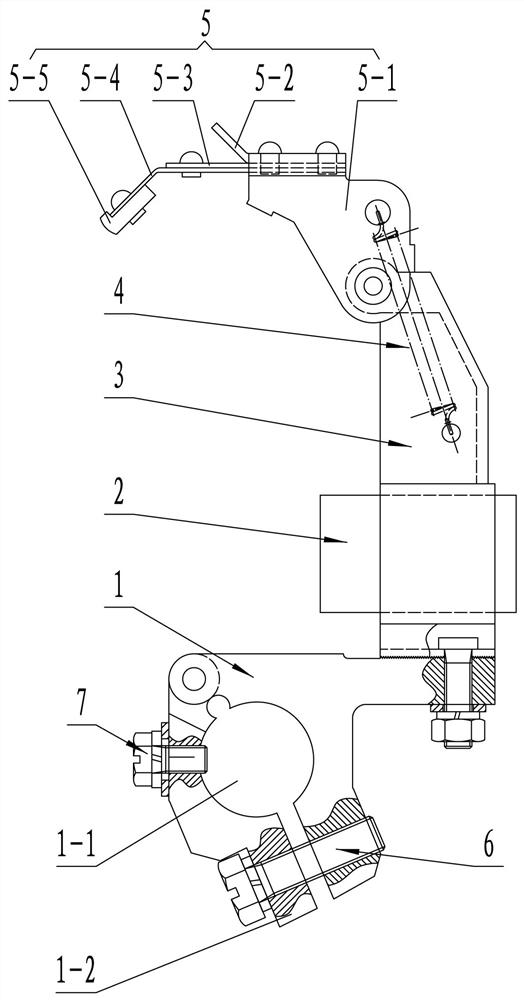

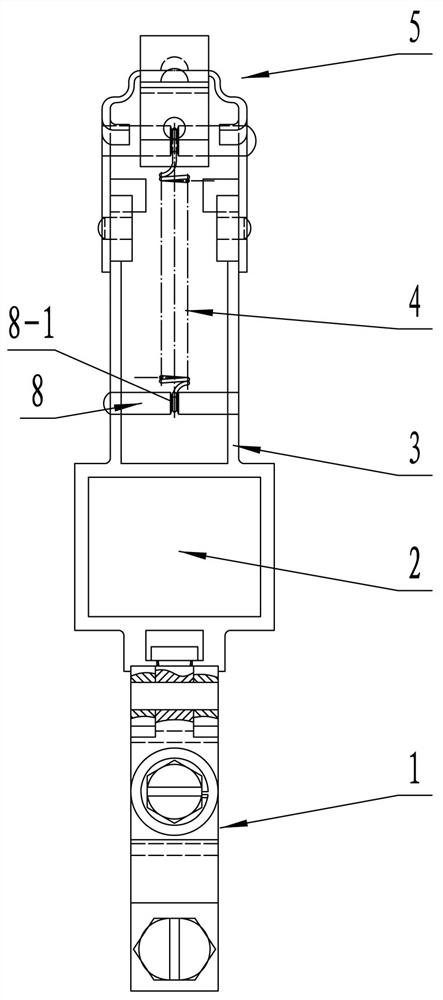

[0032] figure 1 with figure 2 The synchronous motor slip ring surface online repair device shown includes a fixed support 1, a grinding stone 2, a grinding stone installation frame 3, a spring 4 and a grinding stone pressing unit 5, and one end of the grinding stone installation frame 3 is fixed on the fixed support 1 Above, one end of the grinding stone pressing unit 5 is hinged to the other end of the grinding stone mounting frame 3, the grinding stone 2 is mounted on the grinding stone mounting frame 3, and the rotation track of the grinding stone 2 at the end of the grinding stone pressing unit 5 intersects , the spring 4 is connected between the grinding stone mounting frame 3 of the grinding stone pressing unit 5, so as to ensure that when the grinding stone pressing unit 5 is elastically pressed against one end surface of the grinding stone 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com