Double-roller type crushing device for paraformaldehyde production

A paraformaldehyde, roller-type technology, which is applied in the field of double-roll crushing devices for paraformaldehyde production, can solve the problems of reducing the sufficiency of raw material crushing and reducing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

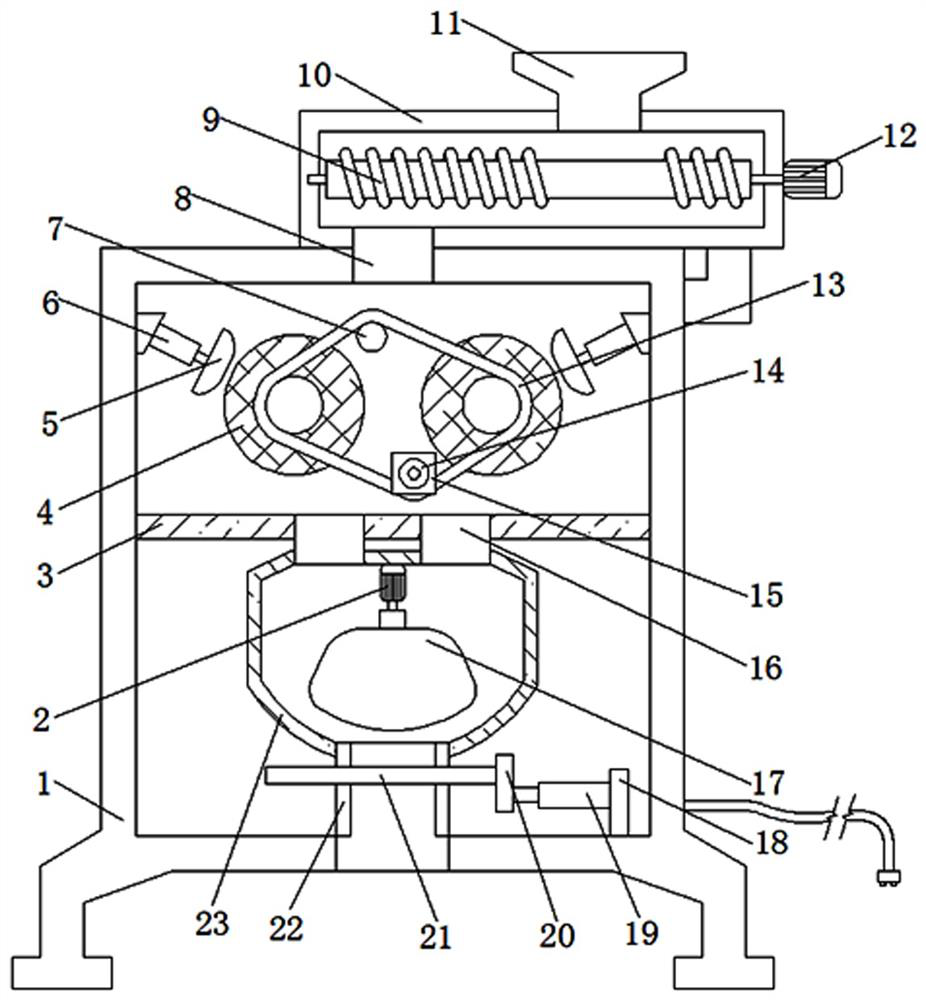

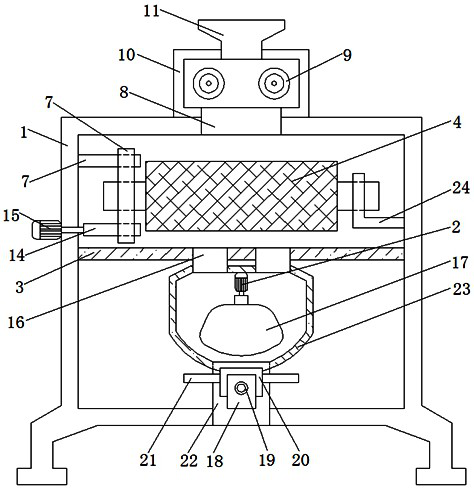

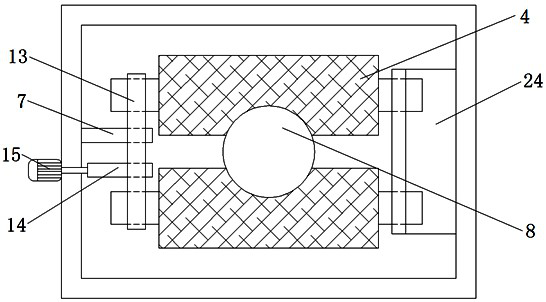

[0029] Example: refer to Figure 1-7 , a pair of roller crushing devices for paraformaldehyde production, the upper side of the crushing machine 1 is provided with a feed port 8, and the feed port 8 and the outlet provided at the bottom of the injection shell 10 are connected to each other, and the injection shell The inside of 10 is provided with material guide roller 9, and the outer bolt of injection shell 10 is fixed with second motor 12, and the output end of second motor 12 is connected with material guide roller 9 through shaft coupling, and the inside of injection shell 10 is set There are two material guide rollers 9 parallel to each other, and the material guide roller 9 includes a spiral part and a polished rod part, the polished rod part is placed between the threaded parts, and the upper side of the injection shell 10 is provided with a through hole flange to fix the feed pipe 11 ;

[0030] Wherein, inside the crushing machine 1, a pair of crushing rollers 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com